How to Print TPU with Creality 3D Printers

PU filament's rubbery consistency offers some unique advantages over PLA, ABS, and other rigid 3D printing materials, but its flexibility requires some special considerations for 3D printing. In this guide, we'll show you how to successfully print TPU with a Creality 3D printer, including recommend slicer settings for specific models such as the Creality Ender 3. We'll also give you our recommendations for printer upgrades to improve TPU printing performance.

Note: Creality Experts receives a commission for items you purchase from this page, at no additional cost to you. For more information, please see our affiliate link policy.

TPU Filament

The specific TPU filament you use, and how well you have taken care of it, has a much greater impact on printing than it does for most other filament types. By making the right choice when buying TPU and storing it properly, you can significantly improve your printing results.

Choosing TPU Filament

TPU filament comes in a variety of shore hardness levels, which is a measure of how flexible the filament is. A lower shore hardness TPU is more flexible, but also harder to 3D print.

To choose the best TPU filament for 3D printing, you should consider how flexible you need your prints to be. TPU filament varies by how flexible it is, which is measured in shore hardness. A lower shore hardness value corresponds to a more flexible filament, while a filament with a higher shore hardness value is less flexible. In addition to the effects it has on the material properties of the completed part, shore hardness also directly affects how difficult the TPU filament is to print--a higher shore hardness TPU will be easier to print because the filament will be less flexible and behave more like PLA or ABS.

For 3D printing, you will often find shore hardness values between 85A (similar hardness to a shoe heel) and 100A (not very flexible, more similar to rigid filament types). A shore hardness of 95A is common for TPU filament, and has a consistency similar to a skateboard wheel. As you shop for TPU filament, it's important to look at the shore hardness value to make sure the filament you are buying will have the material properties you need.

A few of our favorite TPU filaments include the following (all links point to Amazon):

Storing TPU Filament

It's important to store TPU filament in a cool, dry location. Compared to other filament types, TPU absorbs moisture much more readily, and will not print well if it has high moisture content. Many TPU filament manufacturers ship their filament in a special resealable plastic bag, which you should always use when storing the filament.

If you live in a humid climate, cannot store TPU in a sealed container, or want to maximize the quality of your TPU prints, you should consider using a filament dryer. This is a small device that heats up a spool of filament just enough to remove the moisture. Although some people do this in an oven at very low temperatures, we don't recommend putting 3D printing filament in an oven you use for cooking food - its very easy to accidentally overheat the filament and ruin the filament or your oven. There are many of these filament dryers on Amazon, such as the Sunlu S2.

General Guidelines for 3D Printing TPU

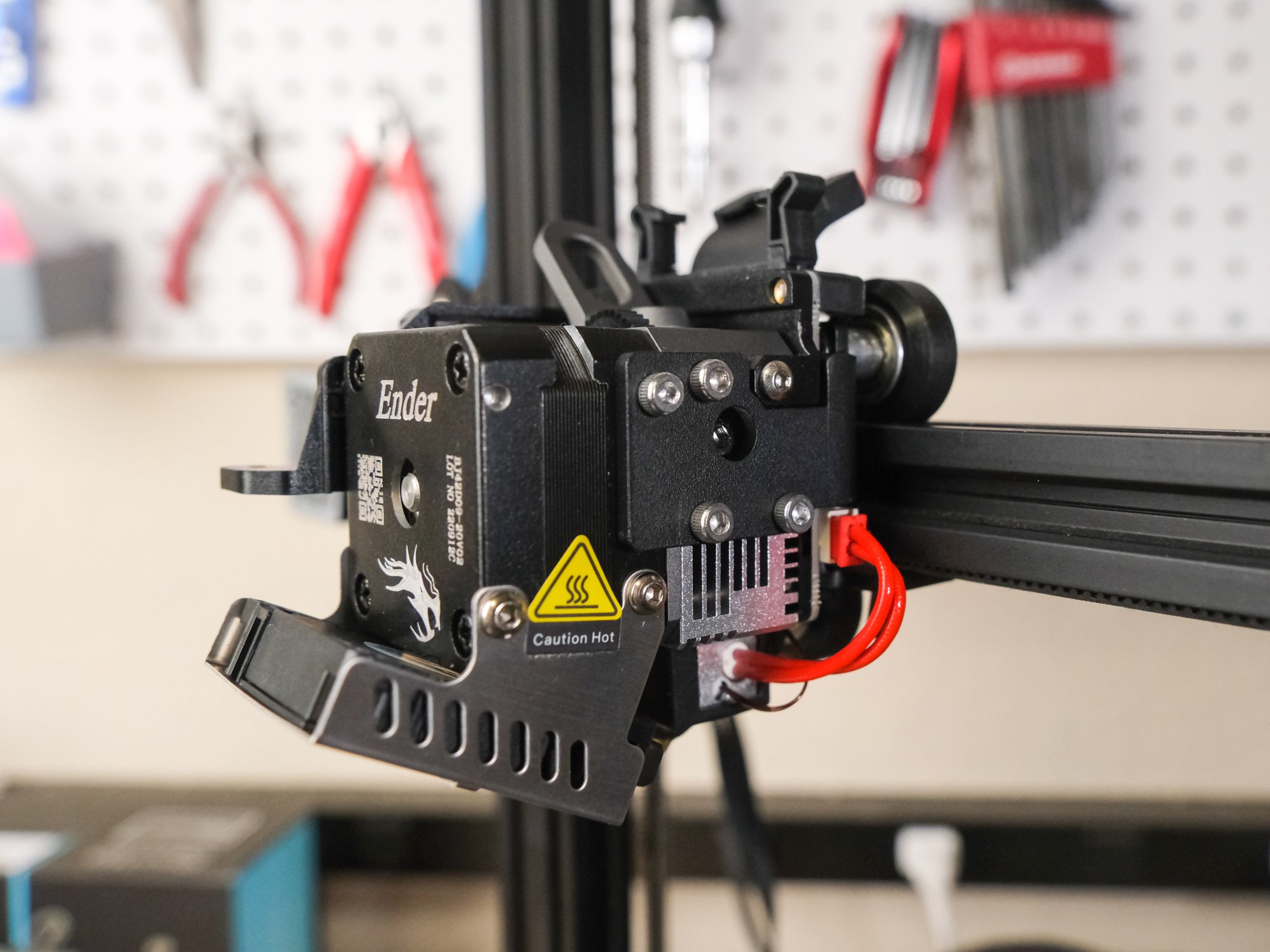

A printer with a direct-drive extruder such as this Ender 3 S1, can print TPU at high quality without much reduction in print speed.

Printing Speed

The most important aspect of 3D printing TPU filament is to print slowly. Because the filament is flexible, the extruder drive gear cannot apply as much pressure to the filament as with more rigid materials. Too much pressure can result in a jam, or on printers that do not fully enclose the filament path after the drive gear, the filament can bend outward from the extruder body and fail to even reach the hotend. As far as how much you need to slow down the printing speed, it depends on a few factors.

First, a higher shore hardness TPU can be printed at higher speeds. For example, if you're using 100A shore hardness TPU, you can probably print at nearly the same speed you use for PLA with no issue. On the other hand, if you're using 95A or 85A TPU, you'll likely need to slow down to 2/3rds or even half of your normal printing speed to ensure reliable printing. You’ll need to experiment to find the highest speed you can use without issue.

Second, the extruder type you're using heavily affects how fast you can print TPU. On a Bowden extruder, you'll have to print significantly slower because the filament path from the extruder to hotend is very long and gives the filament more opportunity to stretch and compress during printing. On the other hand, with a direct-drive extruder you will be able to print closer to the speeds you use for rigid filaments because the overall filament path is much shorter.

Retraction

You will also need to adjust your retraction settings for printing TPU. Since retraction often involves fast movements, it's subject to the same issues as printing too fast. You'll likely find that you need to slow down the retraction speed significantly, and in some cases (such as with a Bowden extruder) you may be better off completely disabling retraction. If you do choose to disable retraction, you will likely need to spend more time clipping strings and blobs on the finished print, but on some Creality 3D printers this may be the only way to reliably print TPU.

Slicer Settings for Printing TPU on Creality 3D Printers

To give you a starting point on slicer settings, we've collected the most important settings that you should change when printing with TPU.

A Bowden extruder will require much slower printing speeds than a direct-drive extruder to avoid jams.

Bowden Extruders (Ender 3, CR-10S Pro V2, CR-10 Max, etc.)

For these 3D printers, you will need to make some fairly extreme changes to retraction and print speeds due to the Bowden extruder. We have successfully printed TPU on these machines with the following settings:

Print speed: 15-25 mm/s

Retraction amount: Disabled completely (no retraction distance, and no extra length on restart)

Hotend temperature: 210-220° C

Bed temperature: 55° C

Part cooling fan: Disabled

Prints with these settings will be time-consuming and may require more cleanup after printing since there is no retraction, but the printing process itself should be reliable and give you good results with TPU.

A direct-drive extruder can print TPU faster and can use retraction, resulting in cleaner prints.

Direct-Drive Extruders (Ender 3 S1, Ender 5 S1, K1, etc.)

On these printers, you can print much faster and can use retraction as long as you slow down the retraction speed.

Print speed: 30-40 mm/s

Retraction amount: 0.6mm retraction distance, 0.00mm extra length on restart, 50 mm/s speed

Hotend temperature: 210-220° C

Bed temperature: 55° C

Part cooling fan: Disabled

In general, we've had great results printing TPU on Creality 3D printers with direct-drive extruders. The above settings should give you a good starting point, although you will likely need to adjust them for your specific brand of TPU based on the results you get from a test print.

Printer Upgrades to Improve TPU Printing

Although Creality 3D printers are capable of printing TPU with no additional modifications, you may be able to improve your TPU printing capabilities by upgrading the extruder on your machine or even upgrading to a different 3D printer entirely. If you find yourself commonly printing TPU parts, you may benefit from one of these upgrades.

Direct-Drive Extruder Upgrade

Recommendation: Sprite Extruder Pro Upgrade Kit (Amazon)

If your 3D printer uses a bowden extruder, the single best upgrade you can make to your existing Creality 3D printer for printing TPU is to add a direct-drive extruder such as Creality's Sprite upgrade kit. A direct-drive extruder will allow you to print TPU more quickly and lessens the chance of print failures. It also allows you to use retraction during printing, which will reduce the amount of cleanup required after printing.

The Creality Ender 3 S1 is a great choice for printing TPU, with its direct-drive extruder and overall reliability.

Although there are multiple direct-drive extruders available for Creality 3D printers, we highly recommend the Creality Sprite Extruder Pro upgrade kit on Amazon. We've had excellent results with this extruder on several of our own machines, and it's compatible with the Ender 3, Ender 3 V2, and other printers in the Ender series. Take a look at the installation guide for the Sprite to get an idea what the process looks like for installing this upgrade.

Recommended 3D Printers for Printing with TPU

Our Recommendation: Creality Ender 3 S1

If you are looking to buy a new 3D printer for use with flexible filaments, we strongly recommend purchasing a printer with a direct-drive extruder. Creality currently offers several printers with direct-drive, and any of them will give you a greatly improved TPU printing experience over a machine with a Bowden extruder. However, our top recommendation is the Creality Ender 3 S1. This printer offers a respectable build volume without taking up much desk space, it's affordable, and importantly, it has the Sprite direct-drive extruder. Our Ender 3 S1 has been one of the most reliable Creality 3D printers we've ever used, and it has shown excellent results when printing TPU. If you find yourself printing TPU frequently, this is a printer that will serve you well.