Creality Ender 3 S1 Pro vs Prusa MK3S+: Detailed Printer Comparison

Does Creality’s new Ender 3 S1 Pro match up against the venerable Prusa MK3S+?

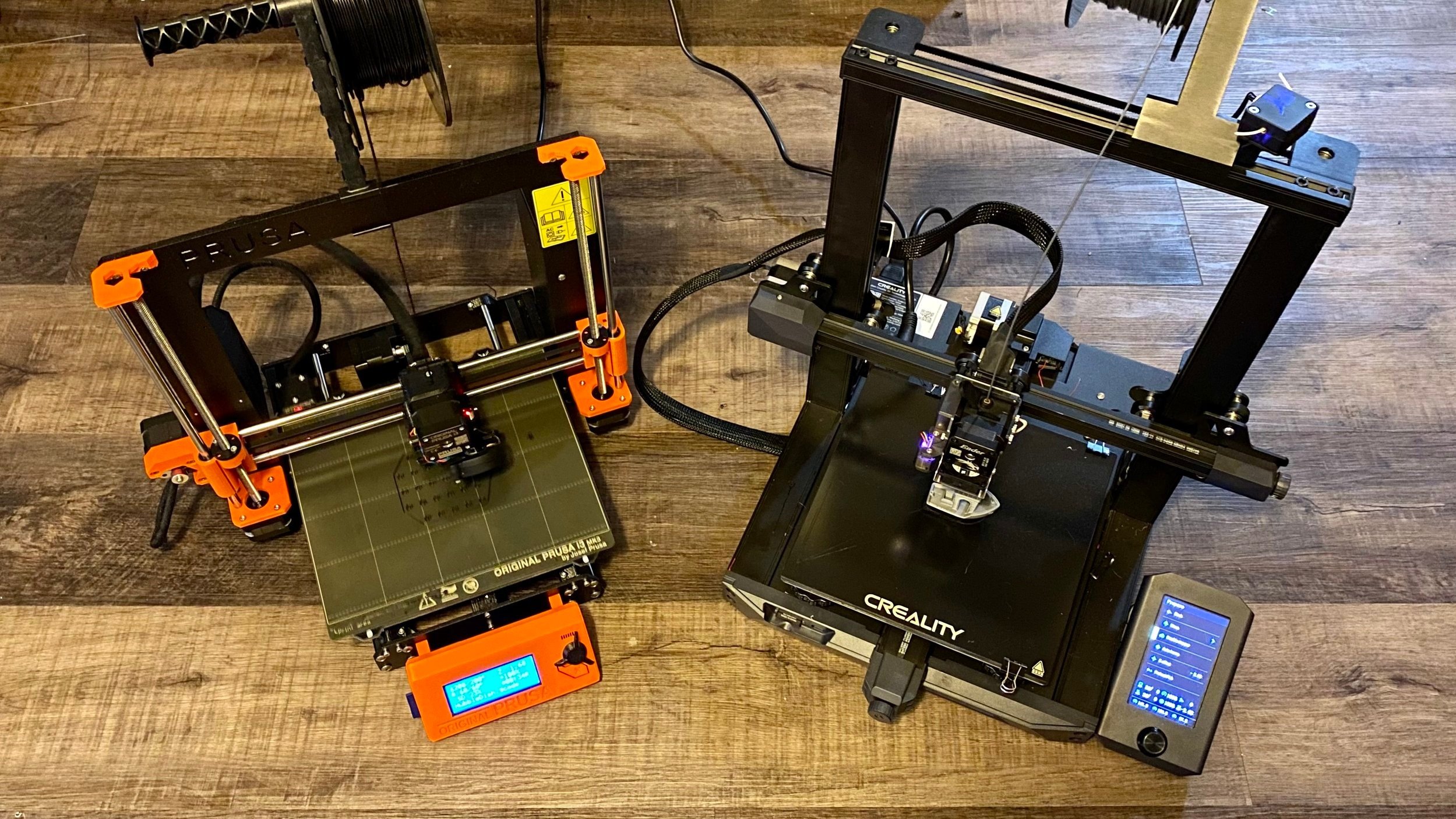

The Creality Ender 3 S1 Pro in many ways feels like Creality’s answer to the very popular Prusa MK3S+, since it includes many of the features that have differentiated Prusa from Creality in the past. Historically, lower-cost Creality 3D Printers did not have many of the major features of Prusa Research’s flagship printer, such as automatic bed leveling and a direct drive extruder. However, Creality has quickly closed this gap with the Ender 3 S1 series, and specifically the Ender 3 S1 Pro, which matches nearly all of the major selling points of the Prusa.

Note: Creality Experts receives a commission for items you purchase from this page, at no additional cost to you. For more information, please see our affiliate link policy.

While we are more familiar with Creality than Prusa, we wanted to see for ourselves how the Ender 3 S1 Pro (View on Amazon) compared the Prusa MK3S+ (View on prusa3d.com), so we purchased an assembled Prusa MK3S+ printer to compare the machines as accurately as possible. After putting the Prusa 3D printer through a lot of test prints and orders for our 3D printing business, we are confident we can give you an accurate comparison against Creality’s machines. First, we’ll take a more detailed look at the feature sets, since there are more differences than initially meet the eye. Next, we’ll look at some other factors that are worth considering when choosing one of these printers beyond the feature set. Finally, we’ll give our recommendations on how to decide which of these 3D printers would be your best choice.

Feature Comparison

Build Volume

Creality is known for its large-format 3D printers, and the Ender 3 S1 Pro has the slight edge here with a 220 x 220 x 270 mm build volume, while the Prusa MK3S+ has a volume of 210 x 210 x 250 mm. This size difference is small enough that it won’t make a significant difference, but Creality does offer many larger printers in their product line, up to 450 x 450 x450 mm. The MK3S+ is currently the largest printer from Prusa, however they will be releasing a larger printer, the Prusa XL, in Q3 2022. The Prusa XL will have a build volume of 360 x 360 x 360 mm.

For the purposes of the Ender 3 S1 Pro vs Prusa MK3S+ comparison, we don’t feel that the build volume is different enough to favor either printer.

Auto Bed Leveling

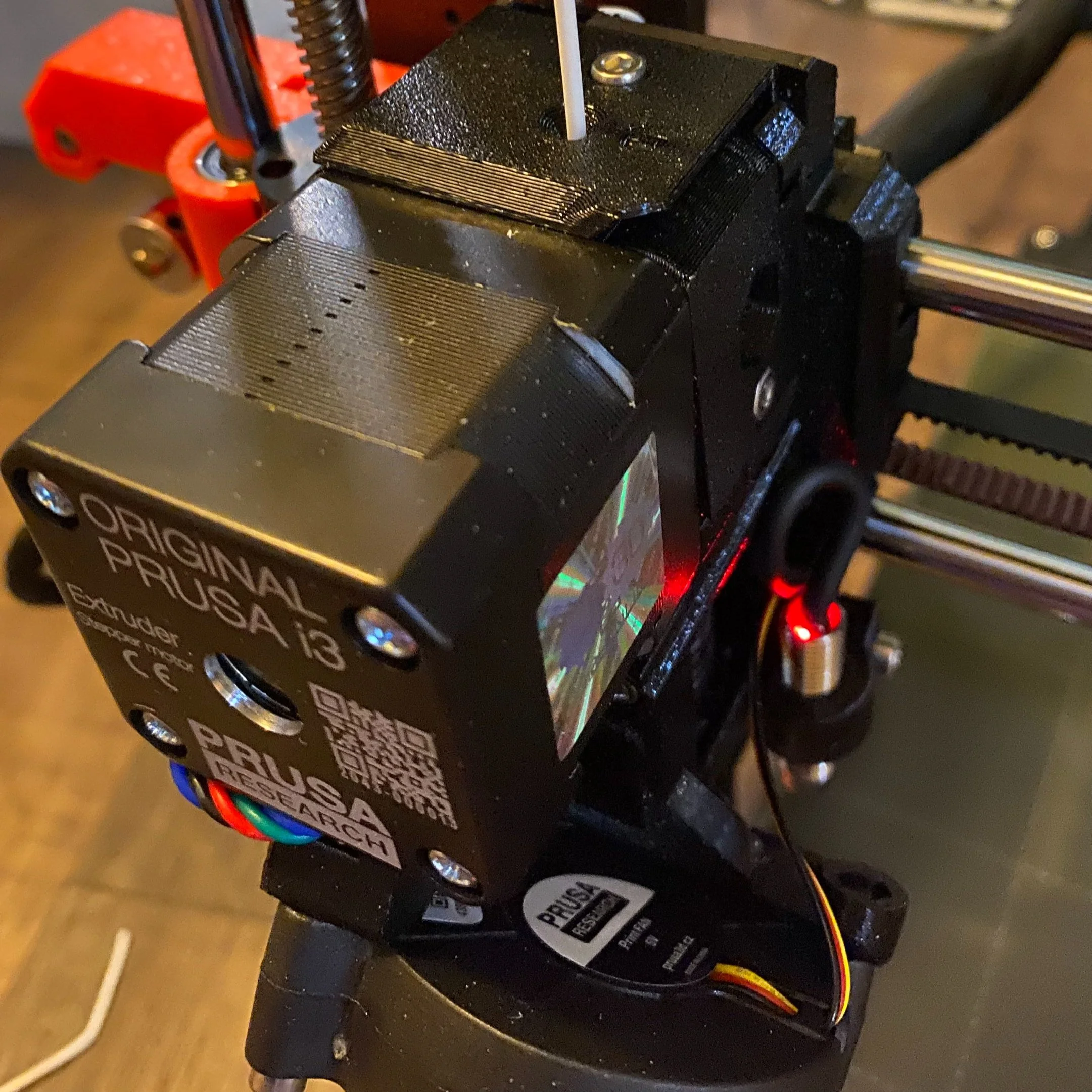

The Prusa MK3S+ uses an inductive probe for auto-bed leveling, mounted to the side of the assembly (see the red LED).

Both the Ender 3 S1 Pro and the Prusa MK3S+ come standard with auto bed leveling, but they use differing methods to achieve the same results. The S1 Pro uses a CR-Touch probe, which uses a moving probe to detect the position of the bed, while the MK3S+ uses a superPINDA inductive sensor. We have had negative experiences in the past with inductive sensors, but we have had great results with the superPINDA probe, and think it is overall a better leveling technology. It does not have any moving parts, which makes it less likely to get damaged by a failed print and less likely to fail over time. As an added bonus, the inductive probe is much faster, so the full mesh bed leveling takes only 15 seconds in comparison to 1-2 minutes on the Ender 3 S1.

While both printers provide capable auto bed leveling systems, the Prusa has a clear advantage here.

Extruder and Part Cooling

Both 3D printers use a direct drive extruder, where the extruder gears and motor are mounted directly above the hot end. Most other Creality machines use a Bowden extruder setup, where the extruder is mounted on the side of the printer and feeds filament to the nozzle using a long tube. Creality designed a new direct drive extruder specifically for the Ender 3 S1 series (branded the Sprite extruder), which has many similarities to the Prusa extruder. This extruder is a major reason we think the S1 series is Creality’s answer to the Prusa MK3S+.

In addition to using direct drive, both extruders use a front mounted part cooling fan, however the fan on the Prusa is a substantially larger blower-style fan that provides more airflow. The improved airflow gives the Prusa an edge on performance when printing steep overhangs without support material.

Both the Ender 3 S1 Pro and the MK3S+ feature an all-metal hot end, which allows printing of higher temperature materials. The standard hot end on most of Creality’s other 3D printers uses PTFE tube to insulate the filament until it reaches the nozzle. While PTFE works well as an insulator, it begins to degrade at high temperatures, so it cannot be used for all materials.

Creality’s Sprite extruder on the S1 Pro includes a spring arm to allow you to manually load and unload filament, while the Prusa is unloaded using an option on the printer interface. We like to be able to load the filament by hand, but using the interface for loading is more beginner friendly.

While both printers include a filament runout sensor, the S1 Pro’s sensor is separate from the extruder on the top bar, requiring you to pass filament through it before feeding it into the extruder. We prefer the Prusa implementation where the filament sensor is integrated into the extruder.

Motion System

While both 3D printers have dual Z motors to ensure the extruder remains stable across the gantry, the Prusa MK3S+ also features linear rails on all axes, which minimizes wobble and other unwanted motion. While we did not see a substantial difference in print quality based on these linear rails, we do expect that they will minimize the maintenance required. On the Ender 3 S1 and other Creality machines, the motion is stabilized using pulleys which roll along the frame, which can occasionally wear over time and require manual adjustment.

Like other Creality 3D printers, the Ender 3 S1 uses a set of 3 pulleys to stabilize each of the axes.

The Prusa Mk3S+ uses linear rails to ensure all axes are very rigid. We didn’t notice a quality difference due to the linear rails, but we expect them to require less maintenance over time.

The Ender S1 has a few features that we like over the Prusa, including built-in belt tensioners on each axis to ensure the belts remain tight, and an alignment belt which physically connects the two Z motors to ensure that they stay in sync and the gantry remains level.

Bed Construction

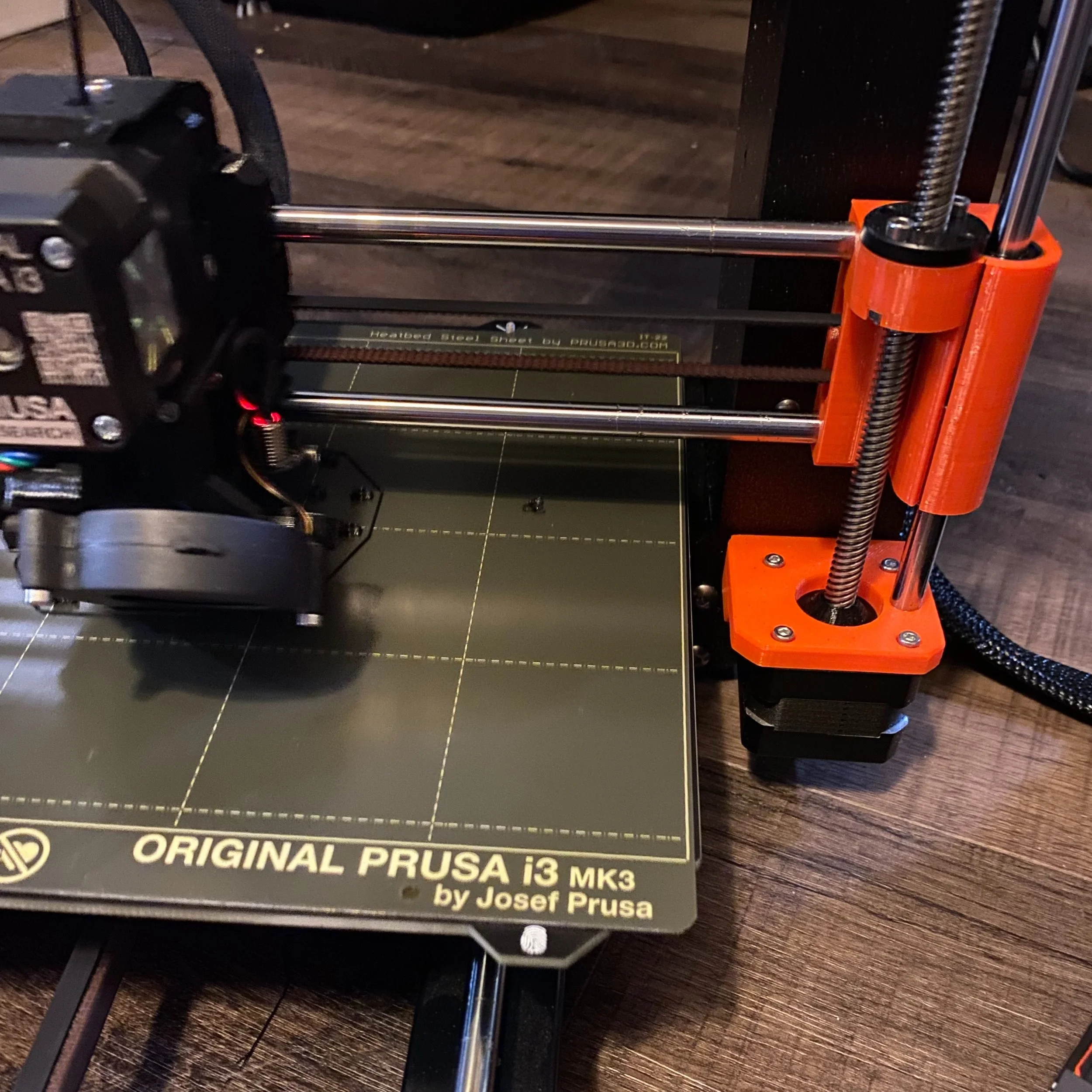

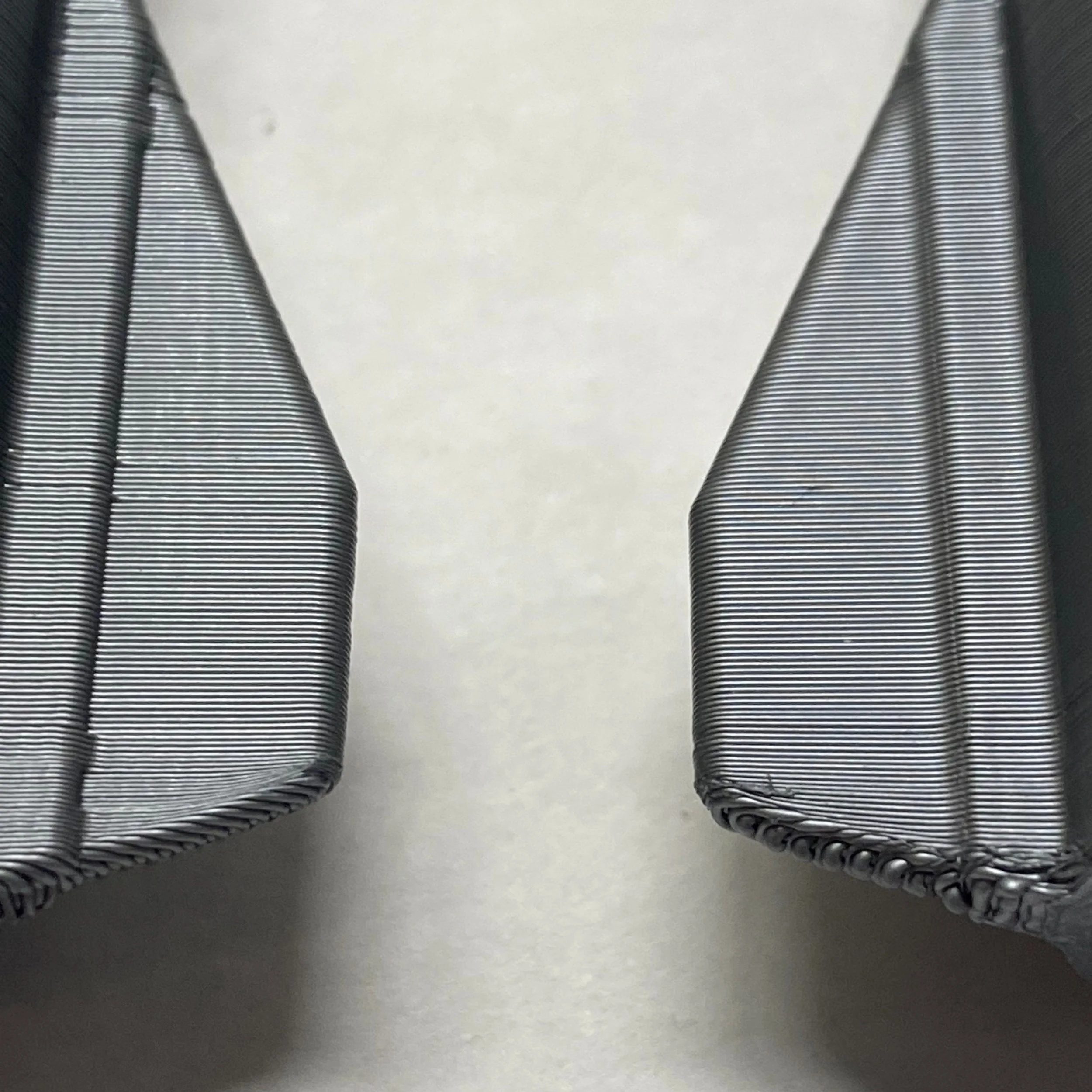

We were happy with the adhesion of Prusa’s PEI bed; it is able to handle small parts without adhesion issues.

Both the Prusa MK3S+ and Ender 3 S1 Pro use a flexible magnetic build plate coated with PEI, which we have found to be a very effective build surface. We typically use glass heat beds with hairspray, but the PEI beds have very good adhesion without the need for any additional coating when printing standard materials. We found that the bed material starts to lose its effectiveness after about 20-30 uses, but it can be quickly restored by cleaning it with acetone. The bed has a smooth surface and leaves a nice glossy base to the prints, and has good adhesion even with small parts.

Note that the Ender 3 S1 (non-Pro) does not use this bed material, and instead uses a magnetic sheet coated with PC, which has very good adhesion, but can be damaged if the nozzle ever contacts it due to an error in calibration.

Both beds can be heated to up to 110C, which is sufficient for all materials.

User Interface

The Prusa MK3S+ uses a simple 4 line LCD screen which offers limited capabilities, but the interface is designed well and we did not feel like it detracted much from the printing experience. The Ender S1 Pro interface uses a more modern graphical interface with a touch screen, which feels more modern and allows for faster navigation. This is an improvement over the Ender 3 S1, which used a control knob with a standard screen.

Getting Started Experience

Ordering and Shipping

Like other Creality 3D printers, the Ender 3 S1 Pro is available at many 3D printer resellers in addition to Amazon.com. You’ll be able to order the printer and receive it fairly quickly—in as little as 2 days with Amazon Prime’s free shipping. Since all Prusa machines currently ship from Prusa Research headquarters in Prague, shipping can take quite a bit of time, typically 1-2 weeks. Additionally, the printers are frequently on backorder, and can take 3-4 weeks for processing. You’ll also want to make sure you include shipping costs in your budget, since shipping is not free and can be a substantial cost if you are outside Europe. We paid around $100 for shipping for our assembled Prusa MK3S+. The kit version does ship in a smaller box, making it less expensive to ship.

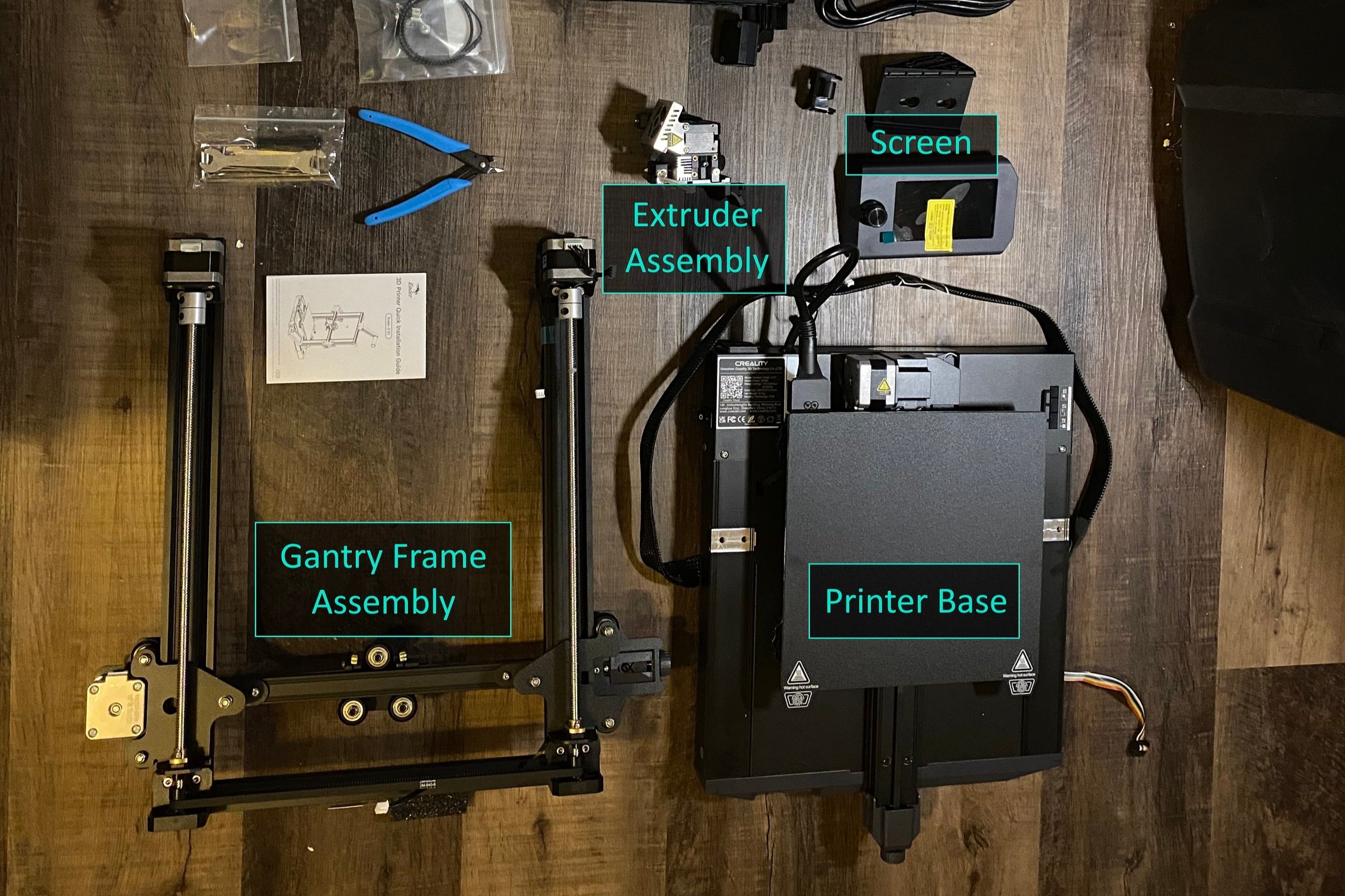

Assembly

Most Creality 3D printers are partially assembled to varying degrees, and the Ender 3 S1 series is one of the easier models to assemble. It takes only 15-20 minutes to assemble the printer. This entails attaching the major frame pieces with screws using the included tools and connecting cabling for some of the electronics. Check out our Ender 3 S1 assembly guide for a detailed look at this process.

The Prusa MK3S+ can be purchased as a kit or as a fully assembled printer for an additional cost. We opted for the assembled version, which as advertised was fully assembled and ready to print out of the box. On the other hand, if you opt for the kit, you will be assembling almost everything, which typically takes about 8 hours to complete.

Initial Setup

When starting up the Prusa MK3S+, it was clear that a lot of thought went into the getting started experience. The printer started with a walkthrough on the LCD that explained each step of loading filament, calibrating the leveling, and starting a test print, which is very helpful if you are new to 3D printing.

For the Ender 3 S1 Pro, getting started is also straightforward and only requires that you load filament and level the bed, which is explained in the user manual. However, the process is not quite as intuitive and may cause some frustration for a new user.

Print Quality

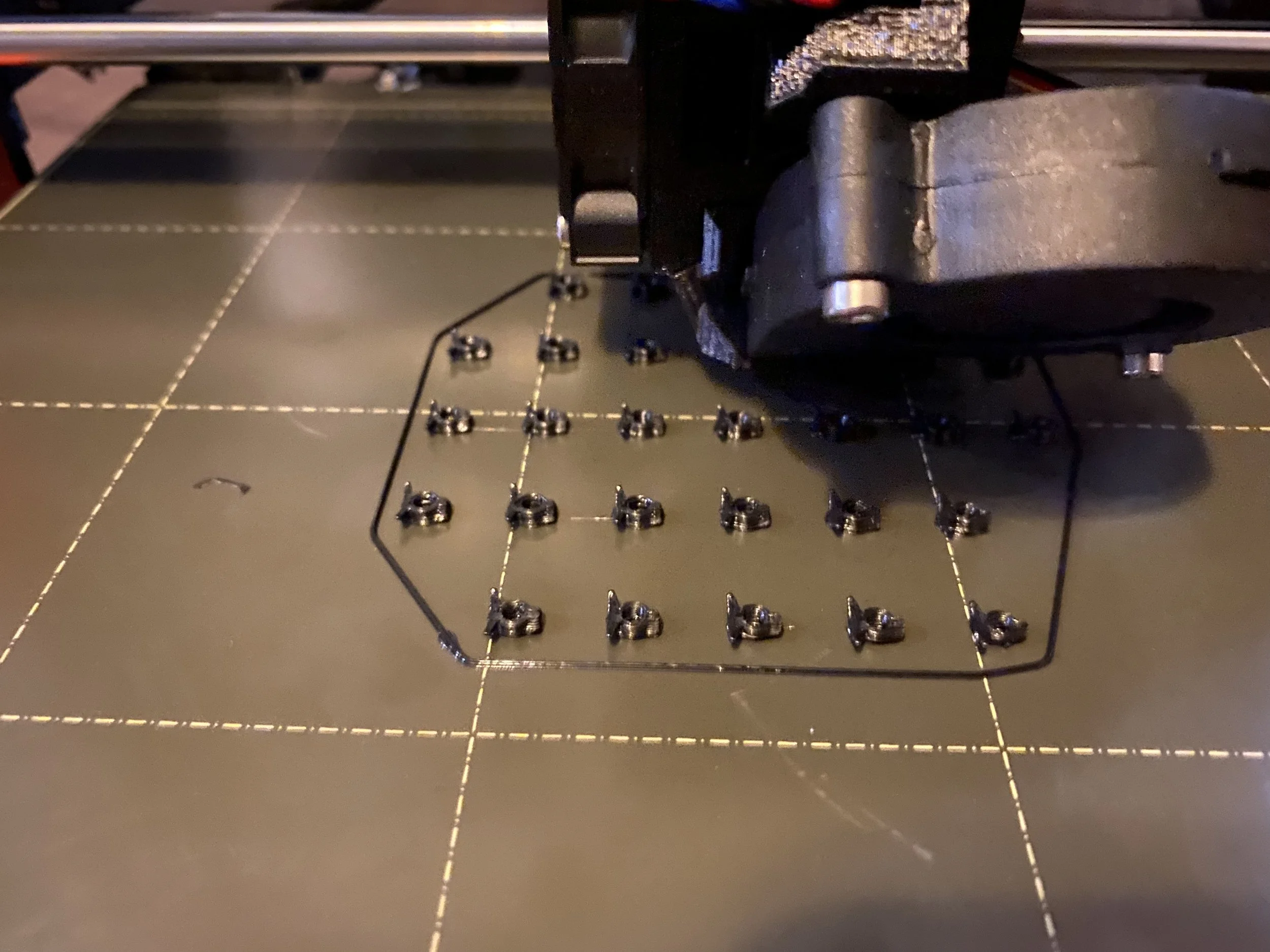

Now that we have examined the features of each of these printers, let’s take a look at how they perform when actually printing. Overall, we found that the quality of prints from both machines was very similar, and we did not notice a significant difference in overall quality. However, there are a few differences that are worth mentioning.

To make the comparison as fair as possible, all of our test prints were printed using the same PLA filament that was included with the Prusa MK3S+ and were sliced using the Prusaslicer software.

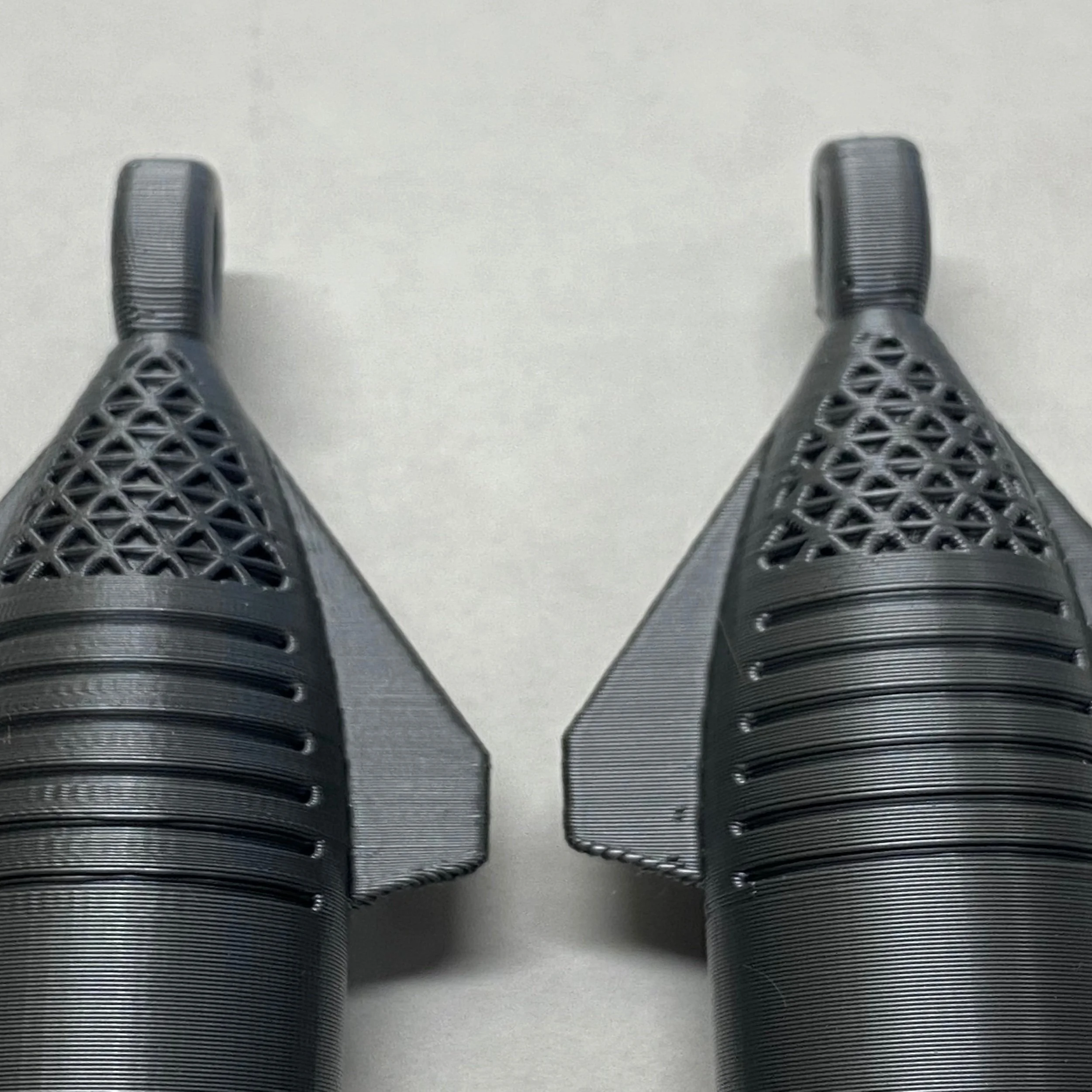

The Prusa MK3S+(left) and Ender 3 S1 (right) both produced very good quality prints. The Prusa print had a bit more stringing, but this is likely easily solvable by calibrating retraction.

This starship model is a good test of overhang performance and the print alignment across layers. Both printers excelled at Z alignment, and the Prusa MK3S+(left) did a bit better with the overhangs than the Ender 3 S1 Pro (right).

Overhang Performance

The Prusa MK3S+ uses a larger blower-style fan for part cooling, and it clearly improves the quality of overhangs. While both printers are able to print steep overhangs, the overhang quality was superior on the Prusa.

Comparing Cost

Though these 3D printers are similar in features and print quality, the Prusa MK3S+ comes at a substantially higher price tag than the Creality Ender 3 S1 Pro. While cost isn’t everything, it is definitely an important factor to consider when purchasing. The Ender 3 S1 Pro is priced in the $500-550 price range (Check the current price on Amazon), and includes free shipping from Amazon (or most other vendors). The Prusa$ MK3S+ starts at the $800-850 price point for the unassembled kit, and is over $1000 for the assembled version (Check prices on prusa3d.com). Shipping is not free, and will add $50-100 to the price tag depending on whether you purchase the kit or the fully assembled version.

There are a number of reasons that explain the large difference in price.

Manufacturing Differences

Creality 3D printers are manufactured in China, while Prusa Research is located in the Czech Republic. Due to lower costs of labor and easier access to other manufactured parts, 3D printers manufactured in China cost less to produce and can support a lower price point. In addition, the Prusa MK3S+ uses 3D printed parts in the construction of the printer. This has a number of advantages for Prusa, such as the ability to iterate quickly on part updates, and is a way for Prusa to extensively test their printers when manufacturing these parts. However, 3D printing at scale is more expensive than traditional manufacturing methods such as injection molding.

For parts that they do not 3D print, Prusa focuses primarily on part quality with cost as a secondary consideration. For example, Prusa uses premium parts for the linear rail system and name-brand Bondtech and E3D components for the extruder and hot end. Creality takes a more balanced approach with the Ender 3 S1 Pro, and reduces cost by producing parts themselves, such as the CR-touch leveling sensor and a Creality branded power supply. Creality has historically focused on cost first, but we have seen that the higher-end printers like the Ender 3 S1 Pro do strike a good balance between quality and cost savings.

Quality Control

It is clear from the moment you open the MK3S+ that Prusa puts a lot of effort into testing and quality control. For our assembled unit, a checklist and test results sheet were included which showed all of the testing that they performed before shipping the unit. Additionally, the printer shipped with a completed test print on the bed, indicating that they run an actual print test on each unit they produce. Creality printers do not go through as rigorous of testing, and in some cases there will be small issues that require adjustment. In our experience of purchasing over 30 Creality printers at retail, we have noticed small QC issues on 10-15% of the printers.

Improved quality control is not free, and is likely a contributing factor in Prusa’s higher price point. The bottom line is that if you prefer to pay more to get a machine that will almost certainly work out of the box without any defects, the Prusa MK3S+ is more geared toward you.

Support

In a similar vein, Prusa provides a much better support experience than Creality. After purchasing a printer, it is easy to get in touch with Prusa’s dedicated support team through their site, since you are buying directly from the manufacturer. With Creality, getting support is more difficult since you will be purchasing through a 3rd party like Amazon. If there are major defects with the printer, Amazon is very good about providing replacement units, however you will not be able to get assistance in repairing issues, and needing to do a full replacement can be a frustrating experience.

That said, since Creality printers are so prevalent, there are many resources available to help you investigate issues on your own (such as our site), and an active online community as well.

The Bottom Line

Before we make our recommendations, take a look at this side-by-side comparison to recap what we have covered so far:

Which Printer is Best?

Our answer is a potentially frustrating “It depends what is most important to you”. While these 3D printers both are comparable in their features, they are targeted at different audiences. Prusa Research is focused on producing the best possible machine without much concern for cost, while Creality tries to balance cost and quality in their higher-end Ender S1 series.

Looking at the printers without considering cost, the Prusa MK3S+ is the better printer, since it matches all of the features and quality of the Ender 3 S1 Pro while also offering superior quality control and a better getting started experience. The Creality Ender 3 S1 Pro (View on Amazon) provides a slightly larger build volume and a better user interface, but these are minor differences. However, the question is whether these benefits are worth the additional cost of the MK3S+, and that answer is very dependent on the user.

For users like us, where we need to have many 3D printers to fulfill orders and are comfortable performing minor repairs on them, Creality is a better choice due to the cost. Looking beyond the Ender 3 Pro S1, Creality has the clear advantage if you are looking to print larger items. Even the Prusa XL (currently in pre-release) with its 360 x 360 x 360 mm build volume cannot compete with Creality’s largest printers such as the CR-10 Max (View on Amazon) that offer up to 450 x 450 x 450 mm of build volume.

However, for a newer user who is looking to purchase a single printer for hobby use and is not as concerned about cost, the Prusa MK3S+ is a solid choice due to the superior getting started experience and the focus on quality above all else.