Sunlu FilaDryer S4 Review: Are Filament Dryers Worth It?

Note: Creality Experts receives a commission for items you purchase from this page, at no additional cost to you. For more information, please see our affiliate link policy.

Filament dryers are a 3D printing accessory with strong adherents as well as big skeptics. We've always been curious about what impact they have on the quality of 3D prints, and whether it's worth using a filament dryer as part of our workflow. In this article, we'll be reviewing the new Sunlu FilaDryer S4 to see whether drying filament really does make a difference, and whether the FilaDryer S4 is a good filament dryer to consider. The FilaDryer S4 is currently on Kickstarter here.

Note: Sunlu sent us a pre-release version of the FilaDryer S4 for review. In accordance with our review policies, we have received no compensation for this review, and Sunlu did not have the opportunity to review our article before publishing. We stand behind our reviews and always strive to give you our best insight into the pros and cons of the products we review.

Why Use a Filament Dryer?

The purpose of a filament dryer, sometimes known as a dehydrator, is to remove moisture from the filament to improve the 3D printing process. When filament is stored in an environment with any humidity, it absorbs the humidity as moisture. Then, when you print with the filament, the moisture expands as it's heated and affects how consistently the filament extrudes from the nozzle. If you've ever heard a popping or crackling sound during printing, or noticed that the extruded plastic appears bumpy, these are strong indications that the filament you're using contains too much moisture.

While moisture affects all 3D printing filament types, it has a much greater affect on TPU and nylon-based filaments. These filament types absorb moisture much more readily that standard filament such as PLA. We always recommend storing TPU and nylon spools in a resealable plastic bag or other airtight container, but even with that precaution, you're still likely to end up encountering moisture-related issues with these filament types.

A filament dryer has a heated chamber that holds one or more spools of filament. As it heats up, it dries out the filament, removing moisture from the plastic to ensure consistent 3D prints. You can either dry the filament before printing, or in some cases, can even feed the end of the spool out of the dryer and straight into your printer.

Overview of the Sunlu FilaDryer S4

Most of the filament dryers we've seen are sized to hold one or two filament spools. In comparison, the FilaDryer S4 is a much larger and more capable dryer, able to hold up to 4 standard-sized filament spools at a time. This makes it a fairly large unit, at 18” wide, 8.75”deep, and 12” tall (457 x 222 x 305 mm). You load filament into the dryer from the top, with two separate doors that swing upward. Then, you can plug in the dryer and use the controls on the front to set your desired temperature, humidity, and run time for the drying process.

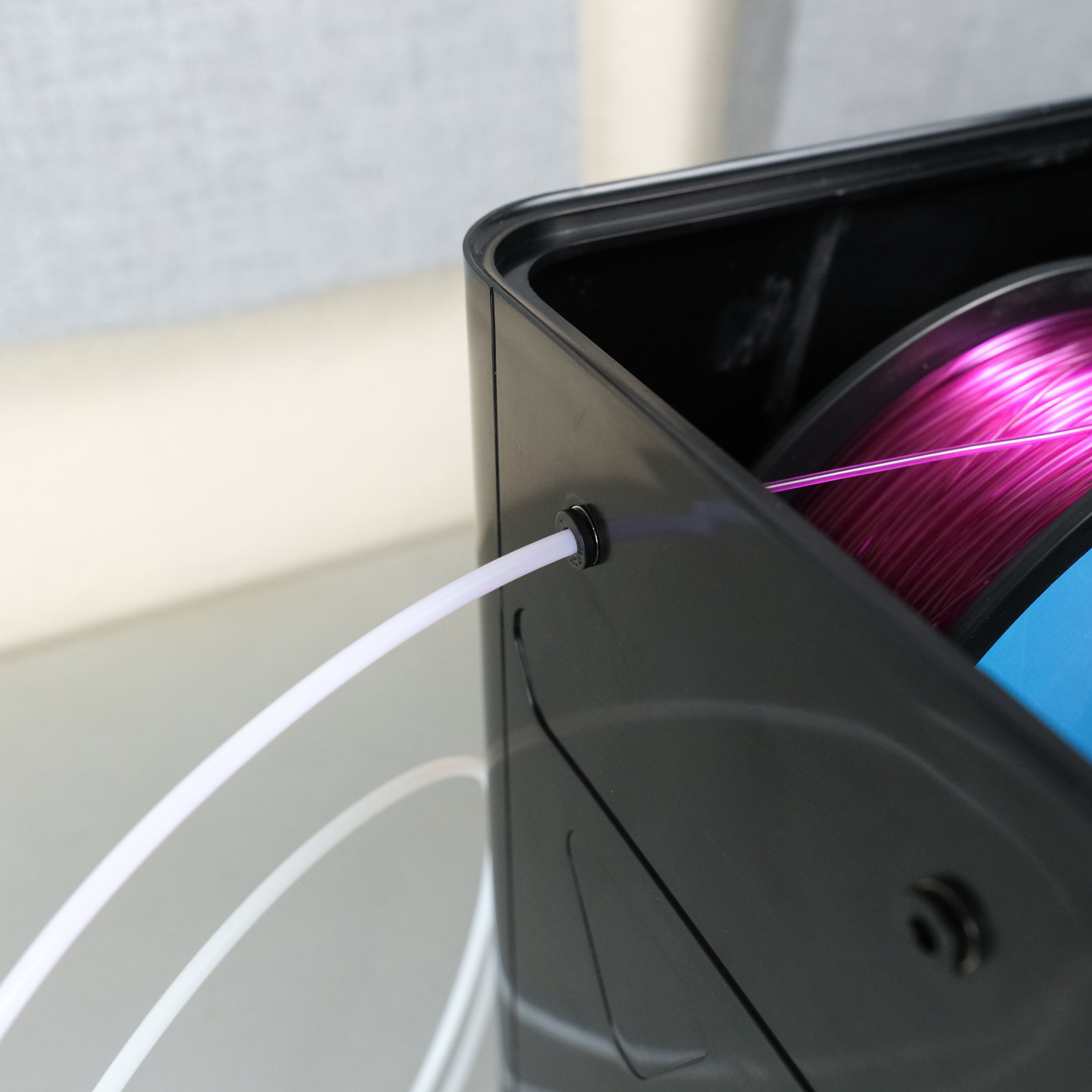

If you want to print with the filament while it's in the dryer, the FilaDryer S4 includes several small exit holes that allow you to feed any of the spools out from either the side or top of the dryer. Inside, the spools sit on rollers, enabling them to feed smoothly from the dryer. We'll cover that use case later in this review.

The overall appearance of the FilaDryer S4 is clean and modern. The physical design is understated--it's basically a large box--but in a way that doesn't draw too much attention. The plastic sides have a glossy and semi-translucent appearance, and are broken up only by a thin green LED strip that animates while the dryer is turned on (and you can turn off the LED strip if desired). The top of the dryer is opaque black plastic, and consists entirely of two large doors that open upward to allow you to load and unload filament spools. Each door has a spring-loaded latch that you push to release it. This is a simple mechanism, but works fine and gives you plenty of space to load the filament.

The control panel is a backlit LCD display, and while it's not a full-color screen, it has a clear, simple set of options for configuring the dryer's behavior. This is where you turn the drying function on and off, set parameters (including target temperature, target humidity, and drying time), and view the current temperature and humidity values.

On the back of the unit, you'll find a physical power switch and the connector for the included power cable. The S4's power cable is a simple AC cable and does not have a bulky power transformer or "wall wart" style plug, which we appreciate.

Using a Filament Dryer

Loading Filament

Using a filament dryer such as the FilaDryer S4 is a simple process. First, you choose up to 4 rolls of filament (although you don't have to completely fill the dryer to use it) and place them inside the dryer. On the S4, the rolls are positioned upright and sit on rollers, which aid in movement if you want to feed filament out of the dryer. We found the large top doors to be very convenient for loading filament--there's plenty of space to fit the filament into the machine, and since the spools just rest on rollers inside the machine, this is as easy as dropping the spool into a box. The doors close easily due to the spring-loaded latches. We weren't quite able to fit one of our bulk 3kg filament spools inside, but there is plenty of room for two standard-size rolls on each side of the machine.

Once the power cord is plugged into the wall and the main power switch on the back of the unit is turned on, the control panel will display a single "power" symbol in the lower right corner. This button turns the dryer on and begins the drying process. You'll hear the fans spin up and it will begin heating to the temperature and humidity target you had most recently configured. If you're drying the same type of filament over and over, this conveniently lets you use the same settings without having to configure the dryer each time.

You can optionally feed filament directly from the FilaDryer S4 to your 3D printer, which allows you to continue drying the filament during the printing process and limits the filament's exposure to dust and other environmental factors. The unit includes a total of 8 exit holes for this purpose, which allows you to feed any of the rolls of filament out through either the side or top, depending on what works best with your 3D printer setup. The holes are actually Bowden tube couplers, and a generous length of Bowden tubing is included. You can insert the tubing into the coupler to help guide the filament to your 3D printer's extruder. This is a useful addition to the FilaDryer S4, and we appreciate the flexibility in being able to route the filament out of the dryer in various ways. We can picture using this unit to feed a small print farm.

Settings

The display on the S4 is simple, but shows all of the settings clearly.

To change the settings, the control panel displays a simple interface consisting of Up, Down, and Set buttons. You can press the Set button to begin configuring the dryer and cycle through all of the settings. The currently-selected setting will flash on the screen to indicate that it's active. Then, you can use the up and down buttons to change the value of that setting. This is an extremely simple interface, and although it might be annoying for a device with many settings, it's a perfect fit for the few settings you'd need to adjust here. After a period of inactivity, the active setting will stop flashing, indicating that the control panel has exited the configuration mode.

The available settings are:

Target temperature

Temperature units (°C or °F)

Drying time

Drying mode (timer or humidity control, explained below)

LED light bar mode

Filament type presets (explained below)

The FilaDryer S4 can operate in two different modes. In the timer mode, you configure a target temperature and a drying time, and the unit will heat up to that temperature and run for the specified amount of time. This is the way most filament dryers operate--the control panel displays the time remaining, making it easy to know when the drying cycle will be complete. You'll also be able to see the current temperature and humidity inside the dryer, letting you monitor the performance of the unit.

The other mode is a humidity control mode, and is aimed at users who want to store their filament inside the dryer. In this mode, the dryer will run until the humidity level reaches 20% and then turn off. Once the humidity level rises to 50%, the dryer will turn on again and heat the filament until the humidity drops to 20% again. This is basically a storage mode that periodically dries out the filament to maintain a low moisture level, and is a useful addition to the FilaDryer S4. We haven't seen this feature on other filament dryers.

The settings also include filament type presets, which are useful for setting the temperature and drying time for different types of filament. Each type of filament, such as TPU, ABS, or PETG, has a different recommended drying temperature. The presets let you select your type of filament and sets the temperature accordingly. Of course, you can always change the temperature manually if you prefer to do so.

Power Draw and Heating Performance

We ran a few tests on the FilaDryer S4 to determine its power draw and temperature accuracy.

From a room temperature start, the maximum power draw of the machine was 433 W, but once the machine is heated up, it consumes power at a rate of 77 watts per hour. This means that running the S4 for an extended period of time is equivalent to leaving a 75W incandescent light bulb turned on. For comparison, a Creality Ender 3 S1 printing TPU consumes approximately 123 watts per hour. This seems like a reasonable power draw for what the S4 is doing, and as long as you don’t run the dryer nonstop, you’re unlikely to notice it on your power bill. But it’s worth pointing out that it will increase the overall power draw of your 3D printing setup.

To measure the accuracy of the control panel's temperature and humidity measurements, we placed a temperature/humidity sensor inside the dryer and logged the results during an extended drying session. From the data we gathered, the temperature and humidity measurements on the screen are reasonably close to accurate, although not completely accurate. When the unit was drying at 131° F (55° C), our temperature sensor was reporting a temperature of 121.1° F (49.5° C). On the other hand, our humidity reading got as low as 14.3%, while the display was showing 18-19%, so our measured result was better than what the machine was reporting. It’s entirely possible that the difference in these measurements is explained by our sensor being located in a different part of the chamber than the S4’s internal sensors. In any case, the measurements are close enough for us to feel confident in the machine’s displayed values.

When we measured these numbers, the temperature in the room was 76° F (24.4° C) at 49% humidity. So the S4 was definitely heating the filament and significantly reducing humidity inside the drying chamber.

How Loud Is It?

In blue on the lower left, you can see one of the fans in the S4. These fans do make noise during the drying process.

Filament dryers use a heater and one or more fans to dry out the filament and circulate air through the drying chamber, so they do make noise and generate heat. We were curious whether the FilaDryer S4 would cause any issues in this area, especially considering its size.

During the drying process, the S4 does exhibit noticeable fan noise. It's hard to describe the impact of any fan noise accurately, but the easiest comparison to make is that it's approximately as loud as a modern Creality printer such as the Ender 3 S1 with the part cooling fan at 100%. However, the S4 has a few things going for it--the fan noise is low-pitched, and it's extremely consistent, with no change in speed or sound. Basically, the unit just hums consistently. Our feeling is that running the S4 will definitely increase the noise level in the room, but it's a noise that is easy to tune out, and it's not overly loud or annoying.

The unit also heats up, and while we were concerned about it heating up the room or table, that didn't seem to be a big problem. When heated to 55° C (a standard drying temperature for many filament types), the sides of the S4 were warm, but not hot, to the touch. The unit has two metal bars that act as feet, which raise the bottom of the unit off of whatever surface it's sitting on. This helps reduce heat on the table surface, and we noted that while the table under the unit was warmer than its surroundings, it wasn't hot by any means. We have no concerns about the FilaDryer S4 discoloring the surface under it or causing any other issues in this area.

Does Filament Drying Improve 3D Print Quality?

The biggest question, of course, is whether it's worth it to use a filament dryer. We were admittedly skeptical towards drying filament, and thought it might only offer only an undetectable or subtle difference in the quality of the completed print. After running some experiments, we've changed our minds, at least for moisture-prone filament types such as TPU.

Comparison of TPU filament before drying (left) and after drying (right). The same slicer settings and gcode were used for both prints. This is an excellent result.

The results aren’t always as dramatic. In this example with PLA, drying the filament improved the print on the right, but we probably still need to adjust some slicer settings to make it perfect.

In the image above, we printed the standard Benchy model using the same roll of TPU with the exact same slicer settings (the same gcode file, in fact). The only difference is that between the two prints, we dried the filament in the FilaDryer S4 at 55° C for 5 hours. As you can see, this made a dramatic difference in the quality of the model between the left (before drying) and right (after drying) prints. In this case, the dryer revitalized the filament, taking it from unusably bad to a perfectly good roll of TPU. This was an excellent result.

Not all of our results were this dramatic. For some filament spools, such as a matte PLA, we saw some improvement, but not significant improvement. In that case, drying still feels worth it, but isn't as beneficial as what we saw with TPU. And in some cases, even a filament dryer can't revive old filament. We had one very old roll of NinjaFlex TPU that was printing very poorly, and even many hours of drying didn't return the filament to a usable condition. This tells us that there's no substitute for storing filament in a cool, dry location, and preferably using an airtight bag or container for sensitive filament types such as TPU. This may also be a good argument for the humidity control mode on the FilaDryer S4.

Based on our results, we think a filament dryer is certainly a good idea for filament such as TPU and nylon that are senstiive to moisture. We've seen significant improvements in 3D print quality after using the dryer, and it's a relatively cheap investment to get maximum benefit from these expensive filament types. For other types of filament, such as PLA, we're less likely to use the dryer on a regular basis, but would probably use it reactively to try to recover a roll of filament that suddenly starts printing poorly.

Should You Buy the Sunlu FilaDryer S4?

As far as filament dryers go, the Sunlu FilaDryer S4 is the most capable unit we've seen. The 4-roll capacity is unmatched by other dryers, and features like the automatic humidity control mode allow you to use the S4 as a storage solution for more sensitive filament types. We found the dryer easy to use, with simple controls and an intuitive physical design. And from our experiments, it clearly does a good job of drying the filament and improving print quality.

The main downside to the FilaDryer S4 is its size. The unit is quite large and will take up a substantial amount of space on a desk or shelf, and if you want to feed filament directly from the S4 to your 3D printer, you'll need that extra space to be located near your printer. The one factor that may offset the size is that you could easily store a number of filament rolls inside the dryer, and the unit isn't that much larger than 4 rolls of filament. Regardless, if space is a concern, a smaller dryer such as the Sunlu FilaDryer S2 [Amazon link] may be a more appealing option.

The biggest downside to the FilaDryer S4 is its size. Here, you can compare the size to a Creality Ender 3 S1, which is a 220 x 220 x 250mm build volume 3D printer.

Overall, we're impressed with the Sunlu FilaDryer S4, and we've seen great results from it, especially when printing TPU. If you need to dry multiple rolls of filament at once and have enough space for the machine, we think it's a worthwhile addition to your 3D printing setup.

Where To Find It

The FilaDryer S4 has not yet been released and is currently on Kickstarter. Sunlu has successfully completed Kickstarter campaigns for some of their existing filament dryers, which leads us to believe this one will likely be fully funded and deliver successfully as well. That said, backing a Kickstarter campaign is not the same as purchasing from a store, and the FilaDryer S4 isn't shipping yet, so keep that in mind.

You can view the Sunlu FilaDryer S4 on Kickstarter here.

If you're interested in buying a filament dryer now, our experience with the S4 leads us to believe the Sunlu FilaDryer S2 would be a suitable alternative, albeit without the large capacity and humidity control mode of the S4. You can find the smaller Sunlu FilaDryer S2 on Amazon here.