Getting Started with 3D Printing for Your Small Business

If you are thinking about using 3D printing for your design business, architecture firm, or other small business, it can be overwhelming to know where to start. With so many technologies to choose from which range widely in cost and capability, you’ll first need to think about the types of parts you’ll be printing and how they will be used. A few common examples of 3D printing applications for small businesses include:

Creating design prototypes for fit or other testing

Custom tools or jigs to improve workflows and efficiency

Creating display models, demos, or customer gifts

Small-run manufacturing of highly customized parts

In this article, we’ll take a look at when it makes sense to hire a 3D printing service versus buying your own 3D printer, and help you get started with each of these options.

Note: Creality Experts receives a commission for items you purchase from this page, at no additional cost to you. For more information, please see our affiliate link policy.

Should I Hire a Service or Purchase a 3D Printer?

Before looking at purchasing a 3D printer, you should consider whether hiring a 3D printing service makes more sense for your application. As you might expect, the cost of hiring a service is significantly more than purchasing raw materials to use with your own machine, but allows you to avoid the upfront costs of purchasing a 3D printer.

When to hire a 3D printing service

If your application has more rigid requirements for material properties, which is typical for end use parts, hiring a service may be the most economical way to incorporate 3D printing into your process. Typically, for these parts you’ll need to use more advanced 3D printing technologies such as SLS Nylon or Multi-Jet Fusion, where the lowest cost machines can cost $20,000 or more, and often have a large footprint and ventilation requirements. Lower cost 3D printers can print parts for some applications, but typically are not capable of printing engineering-grade plastics. Additionally, the Fused Deposition Modeling (FDM) technology used by more affordable printers prints parts in thin layers. This introduces anisotropy in strength, where parts are stronger in some dimensions than in others. While these drawbacks are not an issue for some end use applications, such as display models, prototypes, or custom jigs, lower cost FDM printers are typically not suited for end use manufacturing.

FDM 3D printing is a great choice for internal-use parts and jigs, such as this electronics enclosure for a custom tool.

3D printing excels at smaller production runs since there are no upfront tooling costs, but it does typically cost more per part to order a single part vs multiple due to the overhead required to set up the print job. However, this upfront cost is far less than the tooling costs traditional manufacturing, and 3D printing is often more affordable in the 100-1000 quantity range.

It is easy to get a quote for 3D printing your parts very quickly; most printing services offer an instant quoting tool which analyzes the 3D model file you provide. As long as you can export your design files to a compatible format such as STL or OBJ, you can quickly get an idea of the cost for 3D printing various quantities of your part.

When to buy your own 3D printer

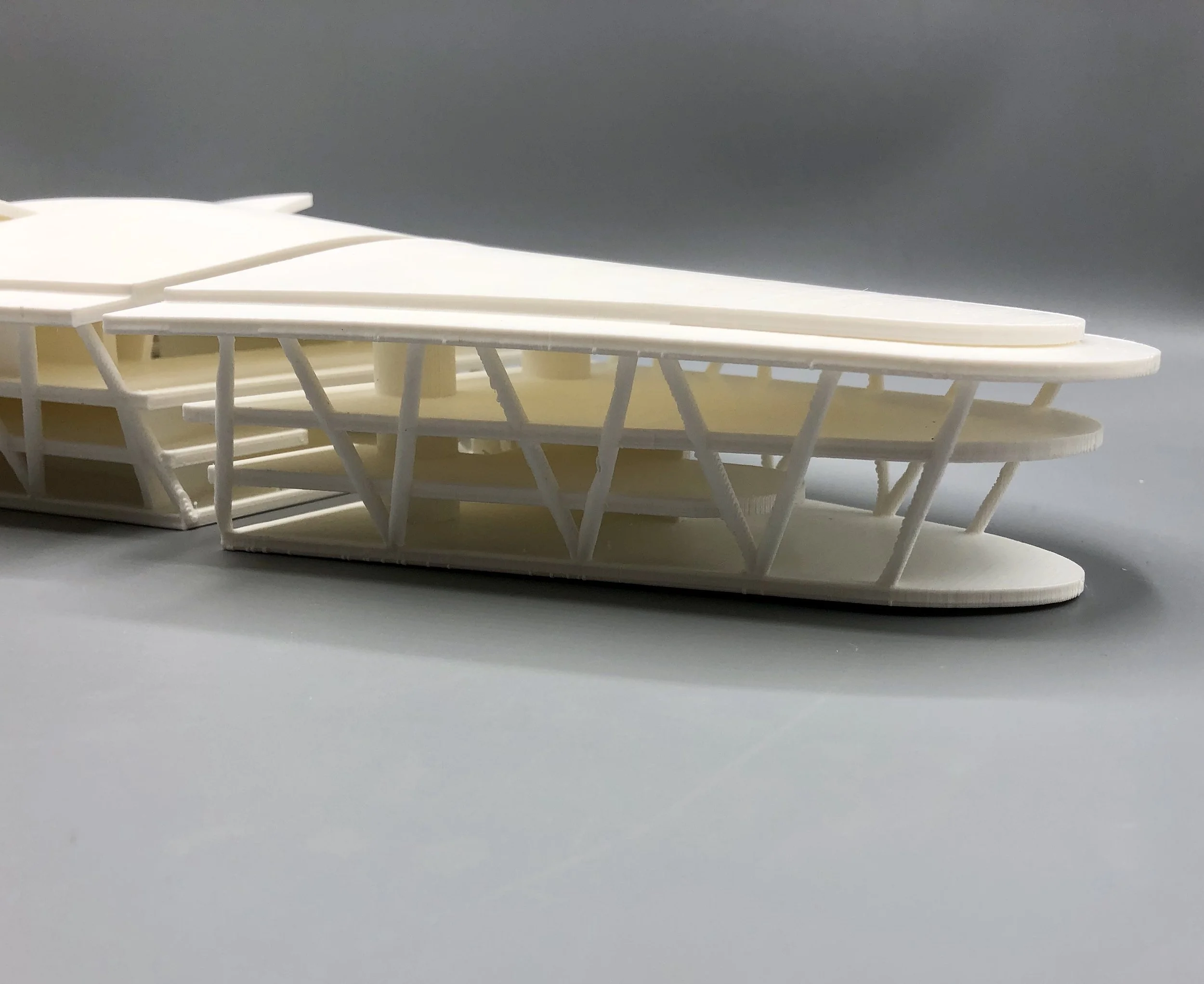

FDM printers are capable of producing detailed models, like this concept architectural model.

If your 3D printed parts do not have specific material requirements, such as creating early prototypes, jigs for your manufacturing process, or display models, purchasing a 3D printer becomes much more attainable. For these types of work, it’s reasonable to use a consumer FDM 3D printer, which provide impressive capability for a very low price. Most consumer 3D printers range from $200 - $1000 in price and are compact enough to fit on a desk. The drawbacks of FDM are typically not a concern for these types of parts, and having your own 3D printer offers a major benefit in addition to lower cost—reduced iteration time. When designing a product for testing, it is critical to minimize the iteration cycle.

Though ordering 3D printed parts from a service is much faster than traditional manufacturing, it will still typically take 3-5 business days to receive most orders from a service. This can add a lot of time to iteration, and discourages rapid iteration on an idea. With a 3D printer in-house, you can print testing prototypes very quickly, typically in 4-6 hours for midsized parts, which will allow you to quickly try designs, test them in the real world, and improve your design.

Pioneer Woman Cookware uses 3D printing to produce early prototypes for look and feel testing to iterate quickly on their products.

Owning a 3D printer can also allow you to “prototype your prototype”. For example, if you are designing a part with rigid strength requirements which will eventually be manufactured using injection molding, you may need a high strength nylon prototype for final testing. However, many tests such as fitment and usability testing can be completed using a part with lower strength. For these cases, you can quickly and cheaply iterate on the design to complete this testing, then order a prototype from a 3D printing service once you have a finalized design.

FDM 3D printers typically have tolerances of ± 0.15% , however the tolerances are larger for small features, with a lower limit of ± 0.2 mm. While this can be an issue for parts that have tight fit tolerances and smaller features, this is not typically a concern for design testing or display models. In addition, FDM 3D printers have very repeatable output, so you can compensate for any tolerance issues by adjusting your model dimensions and can reasonably expect subsequent prints to maintain these adjustments.

Getting started with your own 3D printer

Note: Creality Experts receives a commission for items you purchase from this page, at no additional cost to you. For more information, please see our affiliate link policy.

The Creality Ender 3 Max 3D printer balances ease of use and low cost, and can start producing quality parts quickly.

If you are looking to purchase your own 3D printer, starting with a fully or nearly assembled machine will reduce the amount of time you’ll need to spend on setup. The Creality Ender 3 Max (Amazon link) is a great low cost 3D printer that is easy to assemble and offers a large build volume of 300 mm x 300 mm x 300 mm (Most standard FDM printers are 200 mm x 200 mm x 200 mm). This larger size can open up a lot of options for what you are able to print.

the CR-10s Max is a great 3D printer for larger life size prototypes, such as this full sized wheel rim used for fit testing

If you are looking to print even larger parts, the Creality CR-10 Max (Amazon link) offers a 450 mm x 450 mm x 470 mm build area at a much lower price point than other FDM printers of its size. Like the Ender 3 Max, this printer is mostly pre-assembled and does not require any calibration out of the box.

Every 3D printer will require occasional maintenance, but most maintenance processes are fairly simple and can be accomplished using the basic tools that are included with the printer. Common repairs include:

Replacing the printer nozzle or cleaning the hot end assembly

Replacing moving parts such as bearings or idler pulleys after heavy use

In addition to the 3D printer itself, you’ll also need to purchase the plastic filament used to build the parts. The most common material for FDM printers is PLA, a corn-based plastic which has great properties for 3D printing. It contracts very little as the part cools, resulting in very little part warping and excellent dimensional accuracy. PLA offers good strength for general use parts, but is not suitable for high stress or high temperature applications. There are many brands of PLA available, and we recommend the following brands from our experience:

Overture PLA - an affordable general purpose filament with many color options

Hatchbox PLA - a premium brand that offers a great matte surface finish, excellent for showing off fine details

For more information about the types of filament you can use with a 3D printer and recommended brands for each type, see our filament guide.

You’ll also need to choose a slicer software to use with your 3D printer. The slicer software allows you to import a 3D model in common formats such as STL or OBJ and configure them for 3D printing. The Slicer software generates a GCODE file, which contains instructions used by the 3D printer to produce the part. Fortunately, there are many free slicer options available, and we suggest downloading one before you purchase a 3D printer to get an idea how to prepare a 3D model for 3D printing. Our top slicer choice is Cura, which is available for download on Ultimaker.com. While Ultimaker produces their own 3D printers, Cura is widely used with many brands of 3D printers, and printing profiles are available for nearly all FDM 3D printers on the market.

Exploring 3D printing services

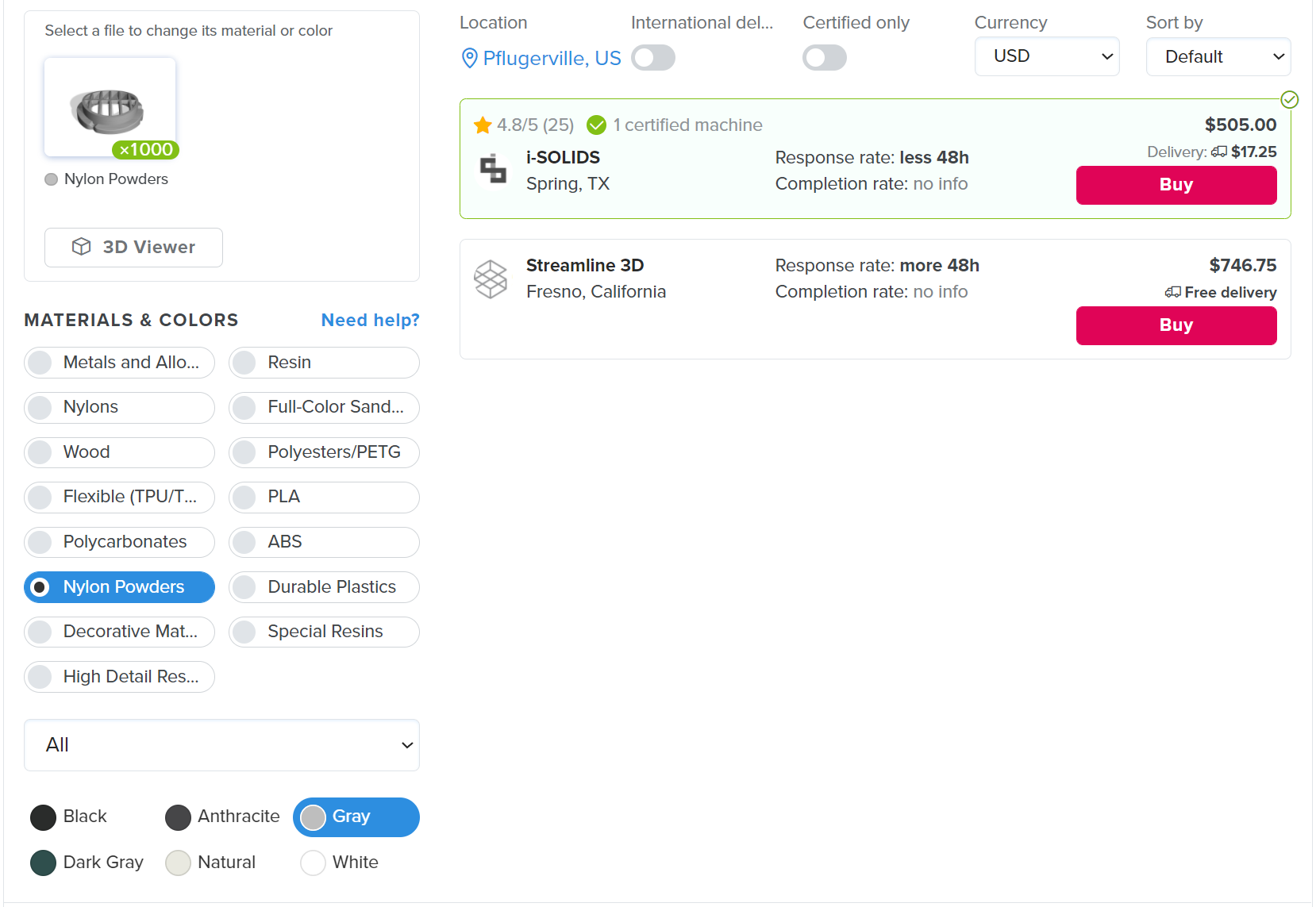

Treatstock allows you to instantly compare prices from multiple 3D printing services for a variety of material options.

There are many 3D printing service son the market today, but a great place to start your search is treatstock.com, which offers a number of technology options from a network of 3D printing services in your area. Even if you are in the research phase, their instant quote tool allows you to quickly get an idea of the price and timeline for getting parts. Unlike other services, you can communicate directly with the company actually printing the parts before you order, so you can make sure there are no issues or concerns with manufacturing.

If you are looking to take advantage of more premium 3D printing technologies, such as full color multi-jet fusion, services such as hubs.com and xometry.com have these technologies available. While these sites provide instant quotes, you won’t be able to communicate directly with your manufacturer.

Next Steps

Now that you know the basics, we encourage you to continue researching the available options; there is a lot to learn about 3D printing! The best way to get started is to experiment with different options, such as getting a quote from a service like treatstock.com, or downloading a slicer like Cura to get an idea what you can expect when printing parts yourself. Whichever route you go, 3D printing is a great tool to have in your arsenal and may be the tool your business needs to improve efficiency or produce parts more economically.