What Materials Can You Use With a Creality 3D Printer?

If you have recently purchased a 3D printer such as an Ender 3, Ender 5, or CR-10s Pro, you may be asking: which filaments can Creality 3D printers use? You may have already tried PLA, the most common 3D printing filament and the sample material that comes with the printer, but there are many other filament types that are compatible with your Creality 3D printer. In this article, we will look at each of these materials, how to print with them successfully, and the brands that we have had success with in our 3D printing business.

Many of these materials can be printed without any modifications to your 3D printer, but a few do require upgrades in order to reach the temperatures required. We’ll take a look at the filament types from easiest to most difficult:

PLA - The most common 3D printing filament due to its ease of printing

PETG - Increased strength and temperature resistance

ABS - Easy to post-process and very good temperature resistance

TPU - Flexible, rubber-like filament

Nylon - Superior strength and heat resistance, but difficult to print

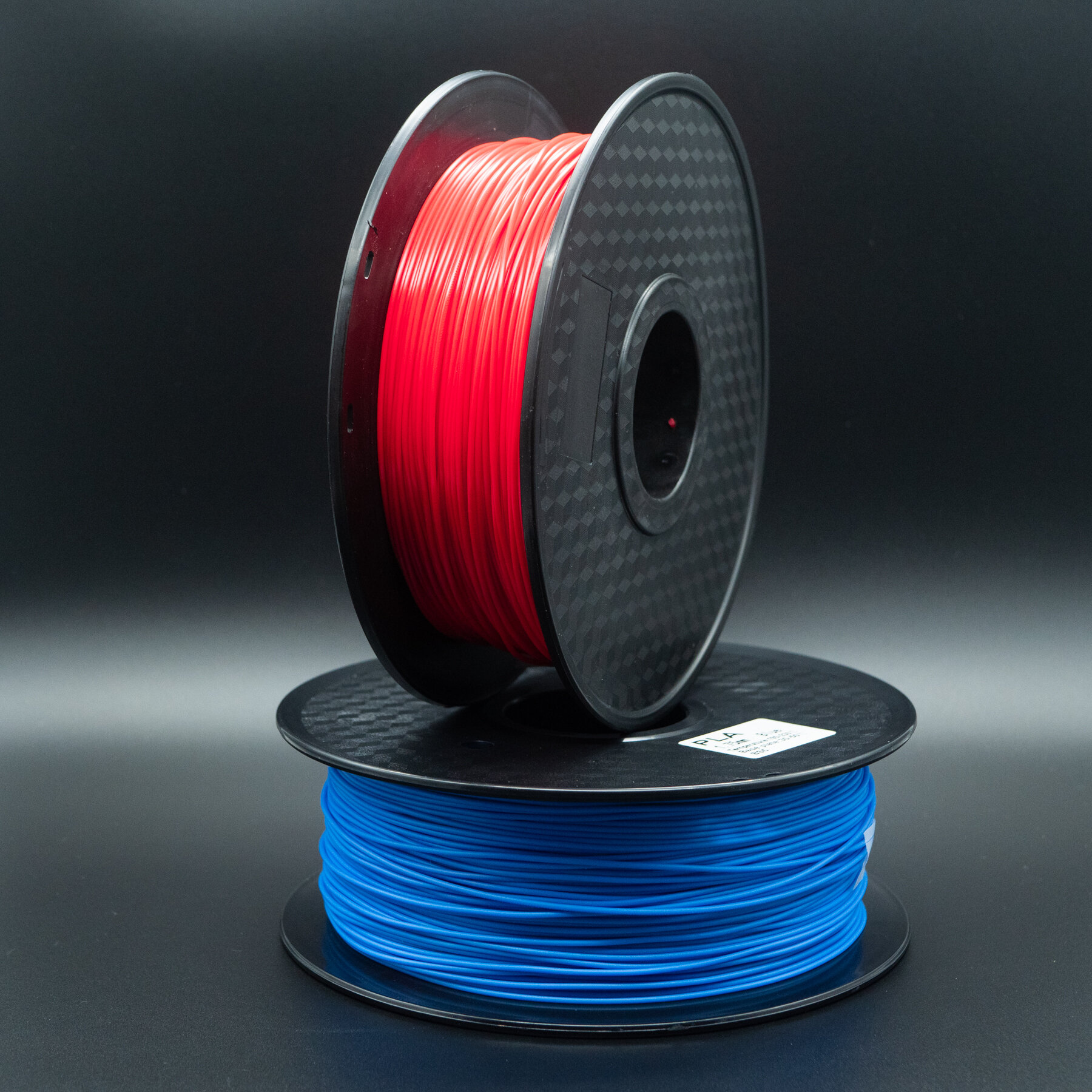

Before getting into the details of each material, be sure to buy only 1.75 mm filament for your 3D printer. All Creality 3D printers on the market use this diameter, and are not compatible with the thicker 2.85mm filament. Fortunately, most filament on the market is 1.75mm.

Note: Creality Experts receives a commission for items you purchase from this page, at no additional cost to you. For more information, please see our affiliate link policy.

PLA Filament

PLA is the most common filament used for 3D printing, and for good reason. PLA’s properties make it ideal for 3D printing:

Low thermal expansion - When PLA cools after being extruded through the nozzle, it does not tend to shrink like many other materials. This prevents your prints from warping or delaminating (splitting across layers) even at room temperature or in cold environments. This also allows you to use part cooling fans with PLA, since the rapid cooling does not cause any problems with shrinking. Using the part cooling fan allows you to print parts with overhangs without the need for support structures in the print.

Low melting temperature - PLA melts at a lower temperature than any other filament, which makes it easier for the hot end of your printer to fully melt it before extruding.

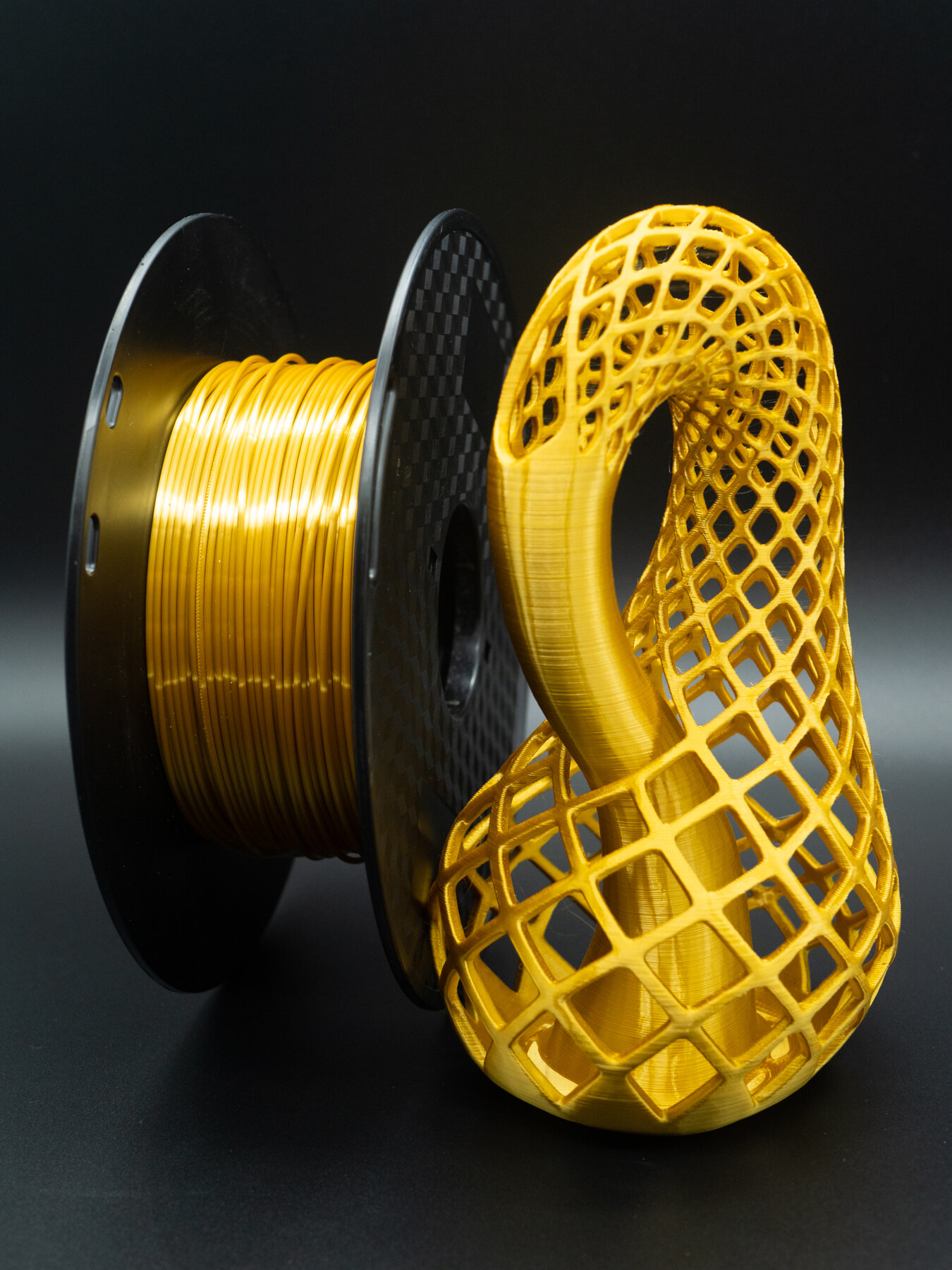

This Silk Gold PLA has a very striking luster, and looks like real metal.

In addition, PLA is widely available, and tends to have the most options in terms of colors. You can even find many specialty colors, such as shiny metallic filaments or a marble finish. We recommend starting with PLA while learning since it is more forgiving than other filaments, and will allow you build the knowledge you need to print successfully with other materials.

Our Recommended Print Settings for PLA Filament

Nozzle Temperature: 200 - 210 °C

You may need to do some experimentation to find the ideal temperature for your 3D printer. If you print too hot, you will start to see more drooping and stringing. If you print too cold, your parts may be brittle or underextruded. We usually start with 200° C and adjust if needed, since different brands of filaments can have different ideal temperatures.

Bed Temperature: 60 °C

While it is possible to print PLA without using the heated bed, we have found that a bed temperature of 60° C improves the adhesion of parts, and since all Creality printers include a heated bed, there isn’t much reason to print without it. One note of caution: increasing the temperature above 60° C to try to achieve better adhesion will backfire, since PLA will start to soften above 60° C, causing it to warp.

Maximum Printing Speed: 55 mm/s

PLA can be printed fairly fast, and we have found that 55 mm/s is a good speed to ensure that your prints maintain high quality. Printing faster is possible, but you may start to see banding patterns on certain features, or brittle parts if the material is not fully melted as it passes through the hot end.

Using a part cooling fan allows for intricate overhangs when printing with PLA.

Maximum Cooling Fan Speed: 100%

Part cooling is standard on Creality 3D printers, and you should always use it with PLA. It will improve the quality of small features and sharp overhangs by rapidly cooling the extruded filament, ensuring it doesn’t droop or deform once placed on the part.

Recommended PLA Filament Brands

While many brands of PLA on the market today will give you good results, its a good idea to read reviews before buying. Based on our experience printing for our business, we recommend Tecbears PLA or Ziro PLA, which offer consistent quality at an affordable price point. These brands also often sell multi-packs at a discounted price.

If you are planning to order multiple rolls, MatterHackers MH PLA is our preferred option since they offer bulk discounts on their already affordable filament, and it is consistently high quality. You’ll need to order at least 2 rolls to get free shipping. Note: Be sure to select 1.75 mm diameter filament for Creality printers.

PLA does have a few drawbacks to be aware of:

PLA begins to deform at around 45° C (110° F), and is not a good choice for high temperature applications.

PLA has poor UV resistance, and is not a good choice for parts that will be used outdoors.

PETG Filament

PETG has a very shiny appearance, and many color PETG filaments are translucent.

PETG is a newer filament type, but it has become a popular choice due to its improved temperature resistance and strength while still remaining fairly easy to print. Although it is affected by thermal expansion moreso than PLA, it is still possible to avoid warping in a room temperature environment. However, it does require higher temperatures and slower printing to get good quality prints.

PETG has a very glossy finish, and many colors are translucent, which makes it an interesting material to have in your arsenal. It also has good UV and temperature resistance, making it a good choice for functional parts and parts for outdoor use. PETG is great for thin-walled objects such as vases. It has very strong layer adhesion, and layers will not delaminate even with very thin walls.

Our Recommended Print Settings for PETG Filament

Nozzle Temperature: 240 - 245° C

PETG requires higher temperatures to melt, but is still in the range of what unmodified Creality printers can achieve. Like PLA, you’ll need to experiment to find the best temperature to balance part strength with excessive stringing.

Bed Temperature: 75° C

Unlike PLA, a heated bed is required for PETG. Fortunately, all Creality printers are able to reach the higher temperatures required. We have also found that PETG does better with slightly higher leveling of the nozzle. If the first layer is flattened too much, PETG is susceptible to “globbing” on the nozzle.

Maximum Printing Speed: 30 mm/s

We have found that printing PETG slowly will dramatically improve the quality and reduce stringing. We typically do not exceed 30mm/s. It can be printed faster if poor surface finish is not a concern.

Maximum Cooling Fan Speed: 30%

PETG can be cooled, but too much will cause substantial stringing. We typically do not exceed 30% of the maximum cooling setting for PETG.

Recommended PETG Filament Brands

We use clear PETG in vase mode to print these protein shaker ornaments due to its strength and shiny finish.

We have used all of these brands of PETG with great results on our Creality 3D printers. Overture is our brand of choice, but we have used a few others with good results as well:

Overture PETG (our preferred brand)

ABS Filament

This ABS part was sanded to be very smooth, and the layer lines are very difficult to see.

ABS is a common plastic used for injection molding, and is a great material when you are looking to achieve a smooth surface finish. It can be easily sanded since it is softer than PLA or PETG. Additionally, you can use acetone to smooth ABS parts to completely remove layer lines. ABS has a matte finish with very little shine, and has superior temperature resistance, even moreso than PETG.

While ABS can be printed on a stock Creality 3D printer, you will need to build or purchase a printer enclosure to print with it effectively. Since it is more susceptible to thermal expansion, it is important to maintain a warm ambient temperature. Small parts can be printed with no enclosure, but anything large will quickly begin to warp and delaminate in a room temperature environment. Even with an enclosure, ABS can be a challenge with certain part geometries, such as long and thin bases or parts with thin walls, which exacerbate the warping issues.

There are a few options available to enclose your printer. You can purchase a portable enclosure (view on Amazon) which can be set up very quickly. You can also build an effective enclosure yourself using foam board, available at most hardware stores such as Home Depot. This option will be much cheaper, but will require a bit of effort to assemble, and is less portable and less attractive. For larger Creality machines such as the CR-10 S4, S5, or CR-10 Max, you’ll need to construct your own enclosure since they are too large for the portable enclosures.

Our Recommended Print Settings for ABS Filament

Nozzle Temperature: 245 - 250 °C

ABS requires higher temperatures to melt, but is still in the range of what unmodified Creality printers can achieve. Like PLA, you’ll need to experiment to find the best temperature to balance part strength with excessive stringing.

Bed Temperature: 100 °C

A high bed temperature is important for ABS to prevent warping, and helps to keep the ambient temperature as hot as possible. All Creality printers can reach this temperature except the CR-10 S4.

Maximum Printing Speed: 40 mm/s

ABS can be printed at moderate to fast speeds, but printing too fast can cause delamination between layers.

Maximum Cooling Fan Speed: None

We exclusively use Hatchbox ABS since it is less prone to warping.

Due to thermal expansion, part cooling cannot be used with ABS, and will cause parts to delaminate due to the rapid cooling. Fortunately, ABS does not typically droop as much as other filaments, so you can still print some overhangs, however for any overhang more than 60°, support material is typically required.

Recommended ABS Filament Brands

Unlike with other materials where there are many brands we like, there is one brand of ABS filament that we exclusively use because we have found that it warps substantially less than others: Hatchbox ABS (view on Amazon). It is a bit more expensive than other options, but it is worth the extra cost because it is easier to print with and yields better results.

TPU Filament

TPU filament is unique because it is very flexible and rubber-like, and allows you to print parts that need elasticity, such as seals or gaskets. Since these parts are flexible, they are extremely impact resistant, making 3D printing with TPU a great choice for drone parts or other components that are subjected to direct impacts that would likely break more rigid materials.

When choosing TPU, its important to look at the Shore Hardness - a metric used to measure how flexible the material is. The lower the number, the more flexible the filament. The difficulty of printing TPU increases with the level of flexibility, so we recommend choosing the least flexible option that will work with your application:

Shore 100A - The most rigid TPU, most useful for impact resistance vs flexible parts.

Shore 95A - Most common for TPU. Similar hardness to a skateboard wheel.

Shore 85A - Softest TPU. Similar to a shoe heel.

The challenge with 3D printing TPU stems from its flexibility. If there is too much pressure on the filament from the extruder, the filament will flex and get caught in the extruder gear, causing the print to fail. This problem is exacerbated by the Bowden extruder setup that comes standard on most Creality 3D printers, where the extruder is separated from the hot end and connected by a length of PTFE tubing. TPU is typically easier to print with a direct drive extruder, which can be purchased as an upgrade. Some Creality printers come standard with a direct drive extruder, including the CR-10 V3 and Ender 3 S1.

We don’t think direct drive offers substantial benefit over a Bowden extruder in most cases, but TPU printing is a case where direct drive has the advantage. If your printer uses a Bowden setup and you plan to print frequently with flexible filaments, you can replace the extruder with a direct drive extruder kit from Amazon.

Our Recommended Print Settings for TPU Filament

Nozzle Temperature: 220 - 225 °C

We like to print TPU hot to ensure as little resistance as possible to the extruder, to prevent jamming.

Bed Temperature: 55 °C

We typically recommend using a glass bed as a printing surface for most materials, but blue painter’s tape offers superior bed adhesion when printing TPU.

Maximum Printing Speed: 15 mm/s

For Bowden extruder setups, TPU must be printed very slowly, with retraction disabled. This will cause your prints to have a lot of stringing, but the strings can be trimmed off with clippers. With a direct drive extruder, you can print somewhat faster and with limited retraction.

Maximum Cooling Fan Speed: 50%

Since TPU is flexible at room temperature, pat cooling has limited effectiveness, but we usually use some cooling. Either way, printing severe overhangs with TPU is difficult without some reduction of surface quality.

Recommended TPU Filament Brands

Most TPU on the market has a shore hardness of 95A, which is a good starting place for testing this material. This hardness is not very flexible, but will give you a feel for how to print with TPU, and is great for impact resistant parts:

Overture TPU - 95A Shore

NinjaTek Cheetah - 95A Shore

For more flexible parts, we use NinjaTek brand flexible filament, since they have the most selection of hardness options available, and are the only brand to offer an 85A option:

NinjaTek Ninjaflex - 85A Shore

Nylon Filament

In a standard Creality hot end, the PTFE tube extends all the way to the nozzle, and will start to degrade when printing above 250 C

Nylon is a difficult filament to print, but the final parts are extremely strong. Nylon also has excellent impact resistance like TPU, but is not flexible. There are a few challenges you’ll need to overcome with nylon and will need to make some modifications to your 3D printer:

It has a high melting temperature - You’ll need to heat nylon to 270 °C or above to effectively print with it. Stock Creality 3D printers can only reach 260 °C since they use PTFE tubing to route the filament to the nozzle, which starts to melt above 260 °C. In order to go hotter, you’ll need to upgrade to an All Metal Hot End, and also update the firmware of your printer to override the maximum temperature limit. There are some blends of nylon that can be printed at lower temperatures (see recommendations below).

It absorbs moisture very quickly - Nylon is notorious for absorbing ambient humidity much more quickly than other filaments, and typically must be dried right before use. If not dry, the surface quality and strength of your parts will suffer. You can purchase a filament drybox enclosure on Amazon to keep filament dry to aid with this issue. We do not recommend using a home oven for this purpose since it is very easy to overheat and melt the filament spool, causing a fire hazard. However, a food dehydrator large enough to fit filament is an effective way to dry it.

It is very susceptible to warping - Like ABS, a 3D Printer Enclosure is critical for success with nylon.

Our Recommended Print Settings for Nylon Filament

Nozzle Temperature: 270-280 °C

This will require upgrading your printer to an all metal hot-end and updating the firmware to allow temperatures above 260 °C. Note that some special nylon blends can be printed under 260 °C - see our recommendations below for specifics.

Bed Temperature: 55 °C

Interestingly, an extremely hot bed does not help with nylon adhesion like it does with ABS. Nylon has a glass transition temperature of 70 °C, so any hotter than this will increase warping. We recommend using a PVA glue stick on glass for the best results with nylon.

Maximum Printing Speed: 30 mm/s

For Bowden extruder setups, Nylon should be printed slowly, since it does have some flex like TPU, though it is rigid enough to support retraction. For direct drive, you can print somewhat faster and with more retraction.

Maximum Cooling Fan Speed: None

Like ABS, cooling cannot be used with nylon since it needs to cool as slowly as possible to reduce warping and delamination.

Recommended Nylon Filament Brands

If you would prefer to print nylon at cooler temperatures and do not want to upgrade the hot end of your printer, we recommend Taulman Nylon 230, which is a nylon blend that can be printed effectively at 230 °C. This nylon filament brand is still difficult to print, requiring that you keep it dry and print it in an enclosure, but can be used on a stock Creality 3D printer. Since this material is a blend, it is not quite as strong as pure nylon filaments, but the trade-off can be worth it for the cooler printing temperature.

If your printer is upgraded and capable of higher temperatures and you are looking for a more pure nylon, Overture Nylon is a great option with an affordable price tag compared to other nylon options.

Next Steps

Now that you have a better idea what material options are available, we encourage you to experiment with a new material both for the challenge and for the new applications you’ll unlock for your 3D printer. If you are able to print other materials successfully on your Creality 3D printer, please contact us; we’d love to hear how you did it!