Comparing the Creality Ender 3 V3 vs. Ender 3 V3 KE

Note: Creality Experts receives a commission for items you purchase from this page, at no additional cost to you. For more information, please see our affiliate link policy.

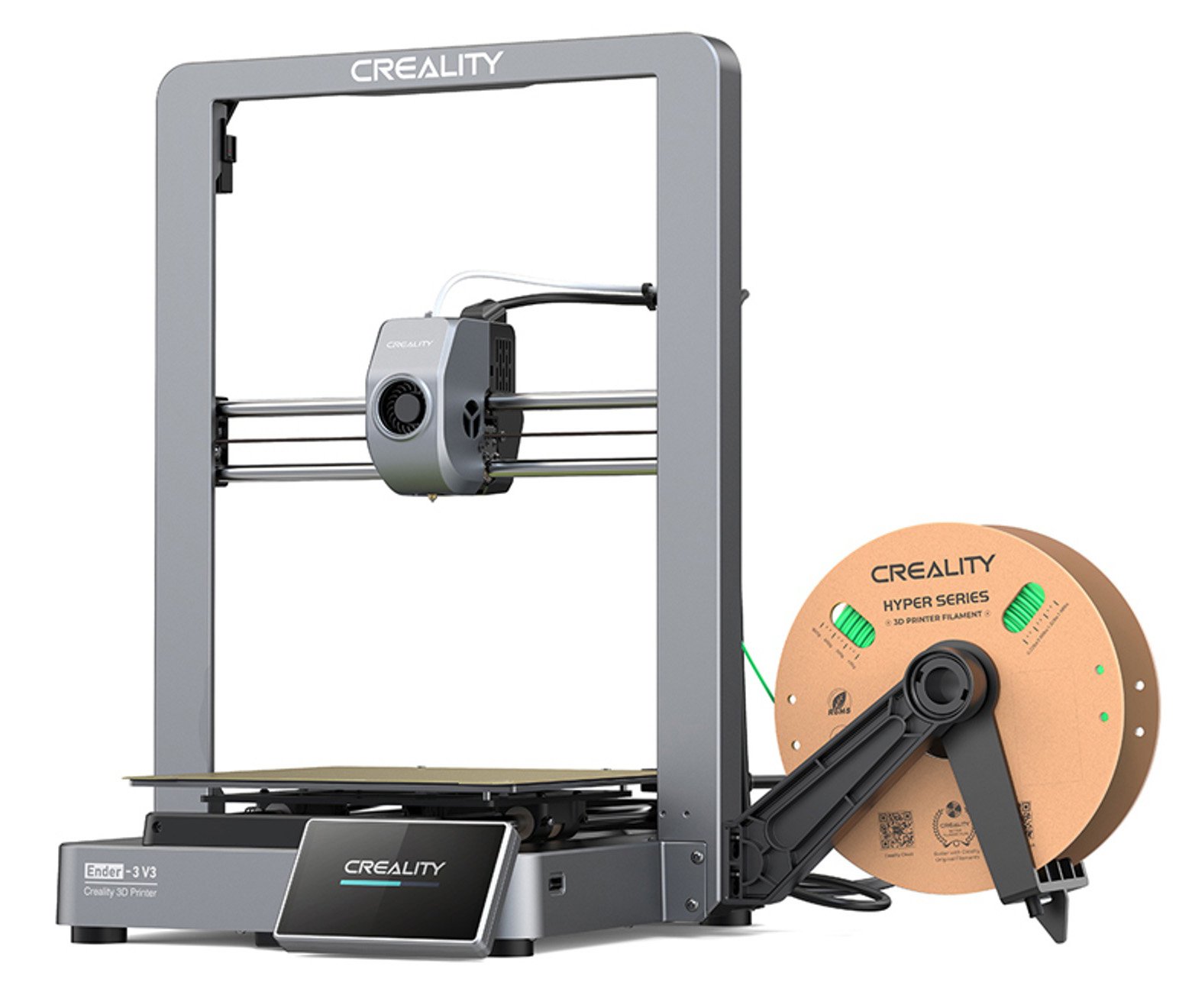

Creality has three models in its V3 lineup of Ender 3 printers: the Ender 3 V3 SE, Ender 3 V3 KE, and Ender 3 V3. While all three of these machines have a lot to offer in terms of features and capability, it can be hard to determine which of the V3 printers is the best choice for you.

Between the three printers, the Ender 3 V3 is the highest-end model in the lineup. We’ve previously compared it to the Ender 3 V3 SE, the entry level option. In this article, we’ll be comparing the Ender 3 V3 with the Ender 3 V3 KE, the midrange printer in the V3 lineup. We’ll start by covering the similarities between the printers, and then cover the differences. For each feature, we’ll explain how each 3D printer implements the feature and give you our analysis of how it may factor into your experience using the printer.

But first, here’s a quick side-by-side look at the two 3D printers:

Vs.

Similarities Between the Creality Ender 3 V3 and Ender 3 V3 KE

The Creality Ender 3 V3 and Ender 3 V3 KE have many features in common. We’ll discuss each one in this section.

Build Volume

The two 3D printers have very similar build volumes of 220 x 220 mm (8.6” x 8.6”) with only a slight difference in the Z dimension; the Ender 3 V3 can print as high as 250 mm (9.8”) while the Ender 3 V3 KE maxes out at 240 mm (9.4”). In our experience, we rarely print models that max out the Z dimension, so this is a very minor difference.

This build volume is the most common size for consumer FDM 3D printers, and is a good balance of offering a decent printable area without making the machine itself too large.

Automatic Bed Leveling

The Ender 3 V3 KE uses a CR-Touch probe for automatic bed leveling.

Both the Ender 3 V3 and Ender 3 V3 KE include automatic bed leveling and automatic Z offset calibration, which eliminate most of the calibration steps that used to be required as part of the getting-started process. However, the two printers do use different sensor types for the leveling and offset calibration.

The Ender 3 V3 uses a newer strain-based system in which a strain gauge sensor detects when the nozzle touches the bed. It uses this system for both automatic leveling and Z offset calibration. On the other hand, the Ender 3 V3 KE uses a Creality CR-Touch probe for automatic bed leveling, and a separate strain gauge sensor for Z offset calibration.

We haven’t experienced any issues with the sensors on the Ender 3 V3 KE in our testing, but the Ender 3 V3’s system is simpler and has fewer moving parts, which we generally prefer.

Direct Drive Extruder

Both 3D printers feature a direct drive extruder, which we prefer over the Bowden extruder found on many older Creality printers. Direct drive extruders are more reliable and offer much better performance with flexible filaments such as TPU. They’re also typically capable of faster print speeds.

The printers use different extruder designs, although we don’t think the differences are too major. The Ender 3 V3 KE uses an upgraded version of Creality’s Sprite extruder, which is a design they’ve used on several previous printers (and that we’ve been very happy with in extended testing). We have no concerns with its functionality or long-term reliability.

The Ender 3 V3 uses a new direct drive extruder design that Creality claims is more reliable and capable of higher print speeds than the older designs. We have no reason to doubt their claims, and this extruder is indeed a new design that looks to have some improvements in strength over the original Sprite design. But since this is a newer design, we don’t have long-term test data on its performance.

Hotend and Supported Materials

The printers are both able to heat to 300° C, so they can print almost all filament types.

The Ender 3 V3 and Ender 3 V3 KE can both heat the hotend to 300° C, which makes them capable of printing almost all standard 3D printing filament types, including PLA, ABS, PETG, TPU, nylon, PA, ASA, and more. Both hotends include a 60W heater for fast heating times.

The print beds on the two machine are also capable of heating to very similar temperatures–the Ender 3 V3 can heat to 110° C, and the Ender 3 V3 KE can heat to 100° C. Both print beds are more than capable of meeting the needs of printing all material types.

There is a slight difference in the nozzles used by the two printers, which primarily affects your replacement options for the nozzle as well as the process of changing the nozzle. We’ll cover that in the Differences section below.

Print Bed Surface

Both 3D printers include a flexible PEI bed surface, which is one of our favorite print bed materials. PEI offers strong adhesion during printing, but easily releases prints once the bed cools. It’s also a durable material that tends to last a long time, and is easy to clean.

On both machines, the PEI surface is flexible and magnetically attaches to the bed, allowing you to easily remove it and flex it to aid in removing stubborn prints. This also allows you to easily replace the bed surface with a different material if desired.

Display and Controls

Both the Ender 3 V3 and Ender 3 V3 KE include a 4.3” color touchscreen controller, which is our preferred control scheme for 3D printers. The only difference between the two is that the Ender 3 V3 has its display in a landscape orientation mounted on the front of the machine, while the Ender 3 V3 KE has a portrait display mounted on the right side of the printer. We don’t have a strong preference between these configurations.

The user interface between the two printers is very similar because both printers use the “Creality OS”, which is based on the open-source Klipper firmware. We’ll cover that more in the next section.

Both printers allow you to connect over WiFi. This is a great feature.

Wireless Connectivity and Firmware

One of the most compelling features shared by both the Creality Ender 3 V3 and Ender 3 V3 KE is their Klipper firmware and wireless connectivity. The firmware improves the quality of printed parts, and the wireless functionality makes the printers more user-friendly than lower-end models such as the Ender 3 V3 SE.

For these printers, Creality is using firmware based on the open-source Klipper firmware, which includes features such as input shaping, pressure advance, and vibration compensation to increase the overall quality and precision of printing. From what we’ve seen, printers with this firmware do produce generally better prints, although the increase in quality over older machines will depend on the specific parts you are printing.

Along with the Klipper firmware, both the Ender 3 V3 and Ender 3 V3 KE include WiFi connectivity. This allows you to control the printer from your phone or computer, so you can upload files for printing wirelessly and start or monitor prints remotely. This is a feature we’ve quickly grown accustomed to on newer 3D printers, and makes the day-to-day use of the printer much easier. Gone are the days of needing to carry a microSD card back and forth to your computer to load a new gcode file for printing.

Next, we’ll cover the differences between the Ender 3 V3 and Ender 3 V3 KE.

Differences Between the Creality Ender 3 V3 and Ender 3 V3 SE

The Ender 3 V3 and Ender 3 V3 KE have a few differences that you should be aware of. We’ll cover each difference in this section, and give you our thoughts about its impact.

Print Speed

The Ender 3 V3 is capable of slightly faster print speed than the Ender 3 V3 KE—up to 600 mm/s print speed with 20,000 mm/s acceleration, compared to 500 mm/s print speed and 8,000 mm/s acceleration on the Ender 3 V3 KE. This isn’t a major difference, but particularly in acceleration, the Ender 3 V3 is a faster 3D printer.

You should know that 3D printers do not print at their maximum speed at all times. Depending on the geometry of the model and your desired quality settings, the machine may only attain its top speed and acceleration for short periods of time during the print. However, higher print speeds do ultimately translate to faster prints.

With the similar top speeds on these two machines, we don’t think you’re likely to notice a major difference in print time on either one. However, the Ender 3 V3 is a bit faster than the Ender 3 V3 KE.

Motion System

The Ender 3 V3 uses an unusual CoreXZ motion system. Is it worth the added complexity? We’re not sure.

The Ender 3 V3 uses an unusual motion system that is uncommon among 3D printers. It’s a “CoreXZ” design that uses two fixed motors to drive the X and Z axes via belts. The Y axis is driven by a separate motor, similar to standard Cartesian 3D printer designs.

The CoreXZ design is intended to reduce the vibration and inertia of the Z axis movement by reducing weight on the gantry, since the motors can be mounted in the base and don’t need to move with the gantry. Although the benefits of this design make sense on paper, we aren’t convinced this change will make a substantial difference in the performance of the printer.

The Ender 3 V3 does use linear rods on both the X and Y axes, which helps reduce vibration at high speeds. However, this isn’t a differentiator against the Ender 3 V3 KE, as that printer uses linear rails similar to the Ender 3 V3’s linear rods.

The Ender 3 V3 KE uses a more traditional Cartesian motion system with separate motors to drive each axis. This is a mechanically simpler design than CoreXZ and is extremely common among 3D printers.

Overall, we don’t think the CoreXZ motion system is a big reason to buy the Ender 3 V3 over the Ender 3 V3 KE, and its benefits are a bit dubious. We may actually prefer the Cartesian motion system on the Ender 3 V3 KE due to it being a simpler design that is more common. In any case, this doesn’t feel like a major deciding factor between the two printers.

Nozzle

The Ender 3 V3’s nozzle is easier to change than older models.

The Ender 3 V3 has a new nozzle design in which the nozzle and heat break are a single piece. The heat break is bimetallic, which should reduce heat creep in the hotend and improve the reliability of the printer. Creality also advertises that this nozzle design allows for “one-handed nozzle changes”, which could be a benefit if you want to be able to easily switch between different nozzle sizes.

In contrast, the Ender 3 V3 KE uses a nozzle that is more similar to the common “volcano” style nozzles, like the one found on the Creality K1. With this design, the nozzle is a separate piece from the heat break.

One downside to both nozzle designs is that they are less common than the older nozzle style found on most other Creality 3D printers. This may make it more challenging to find replacement nozzles, and you’re likely to pay a bit more for replacements.

Physical Design

In broad strokes, the Creality Ender 3 V3 and Ender 3 V3 KE share the same rough design as most consumer 3D printers, with a print bed that moves back and forth in the Y axis and an X carriage that runs along a gantry. The gantry raises in the Z axis, guided by two vertical supports. However, beyond those basics, the two printers do have distinctly different physical appearances.

The Ender 3 V3 KE looks largely similar to previous Creality 3D printers, although it’s a more polished design that hides many of the wires and mechanisms that were exposed on older models. The display attaches to the right side of the printer, making it easily accessible, but unfortunately adding to the width of the machine. The filament spool mounts to the top of the printer. Most of the edges are smooth or curved, and the printer has a sleek appearance, although most of the enclosure pieces are made of plastic.

On the other hand, the Ender 3 V3 introduces a new aluminum design that looks cleaner and more modern than any of the other Ender 3 printers. We hope this is the new design direction for Creality’s higher end machines, because it does look more premium than the black plastic used on most of their other 3D printers. The base and vertical supports are both diecast aluminum, which is both durable and attractive.

The Ender 3 V3’s display attaches to the base on the front of the printer, but unfortunately you don’t gain any horizontal space because the filament spool is mounted on the right side of the printer. This means the Ender 3 V3 will fit in an area with less vertical clearance than would be needed for the Ender 3 V3 KE, but we typically find ourselves struggling for more desk space, so we’d prefer to see a top-mount option for the spool.

In our opinion, the physical design probably shouldn’t be a major consideration in your choice between these 3D printers. Both machines have a clean design and we don’t have any concerns about either design in a functional sense. But if looks are important to you, our opinion is that the Ender 3 V3 wins in this category.

Which 3D Printer Should You Choose?

The Ender 3 V3 is undoubtedly the better 3D printer, but the improvements over the KE are fairly minor.

With the Creality Ender 3 V3 being the top-end model in the V3 series and the Ender 3 V3 KE being the midrange model, these two 3D printers have a rather similar set of features. There are a few areas where the Ender 3 V3 does improve on the KE, such as its physical design, quick-change nozzle, and faster print speed. But whether those features are worth the added cost over the KE is harder to answer. Here’s what would cause us to choose each of these machines over the other:

If you’re willing to pay a bit more money up front for a more attractive and slightly more capable printer, the Creality Ender 3 V3 is what you’re looking for. Its improvements over the Ender 3 V3 KE, while each fairly minor, collectively make a good case for its added cost. It’s a 3D printer we’d be happy to use ourselves, and the fast print speeds and Klipper firmware make it a modern machine that is competitive even against more expensive 3D printers.

The Ender 3 V3 KE is an unbeatable value in 3D printing.

The only real flaw with the Ender 3 V3 is that in some cases, its improvements may add more complexity than value. For example, the CoreXZ motion system is complex without being clearly beneficial, and the quick-change nozzle design, while convenient, makes replacement nozzles harder to find.

On the other hand, if you want to balance cost and capability, the Creality Ender 3 V3 KE provides almost all of the most important features of the Ender 3 V3 at a notably lower cost. With the same Klipper firmware, WiFi connectivity, and material support, and with almost the same print speed as the Ender 3 V3, the Ender 3 V3 KE is an unbeatable value in 3D printing. It’s one of our top recommended 3D printers right now, and we think it gives you more value per dollar than the more expensive Ender 3 V3.

You can check out both 3D printers using the links below, or keep scrolling for a side-by-side comparison of their features and specifications.

If you’d like to compare other printers, take a look at our 3D Printer Comparison Tool. This tool lets you view multiple 3D printers side by side to easily compare features.