Comparing the Ender 3 vs Ender 3 Neo

Creality's Ender 3 has been a highly popular entry-level 3D printer since its release in 2018. Will the launch of the Neo series upset the Ender 3's dominance in its segment, and if you’re looking for a new 3D printer, should you go for the Neo over the original? We'll try to answer this question by comparing the Ender 3 with the Ender 3 Neo in this article.

Note: Creality Experts receives a commission for items you purchase from this page, at no additional cost to you. For more information, please see our affiliate link policy.

Since the original Creality Ender 3 launched in 2018, the 3D printer industry has undergone a tremendous transformation. The early versions of the Ender 3 were fraught with issues, but Creality engaged its customers to improve the product and make the Ender 3 series easier to use and more capable. In the years since, Creality made multiple improvements to the Ender 3 design and has released multiple major revisions of the printer. In a nutshell, Ender 3 is a battle-tested product that enjoys a significant fanbase even today.

Now, the Creality Ender 3 Neo (Amazon link) arrives as a potential upgrade to the Ender 3 within a similar price range. If you’re looking to buy a new 3D printer at a low price and the Ender 3 has caught your eye, you have an obvious question: should you go for the Ender 3 Neo, considering the marginal price bump?

To answer that question, we will analyze what's new in the Ender 3 Neo and whether the new features really make it an upgrade worth considering over the Ender 3. If you're looking for a short answer, here's a quick overview of the most significant new features you'll find in the Ender 3 Neo:

CR Touch auto leveling system

All-metal single gear extruder

Carborundum glass bed

For a more detailed comparison of the two 3D printers, and our thoughts on whether these upgrades matter, keep reading.

Vs.

Ender 3 vs. Ender 3 Neo: Similarities

In general, the Ender 3 Neo does not deviate from the Ender 3 in terms of design philosophy. The two 3D printers look nearly identical at first glance, but there are some important differences. Let's take a quick look at some of the features the Ender 3 Neo has retained from the Ender 3.

Build Volume

The Ender 3 Neo retains the 220 x 220 x 250 mm build volume that has become the standard on Ender 3 series 3D printers. This form factor allows Creality to design truly desktop-size 3D printers that occupy a small surface area, while still producing relatively large prints thanks to the elongated Z axis. In cramped spaces like student dorms, workbenches, and other spaces, the shrunken footprint of the Ender 3 is a big advantage – a feature that Ender 3 Neo carries forward. Both printers share a similar footprint.

DIY Assembly

Most other 3D printers either ship fully assembled or as complete DIY kits. However, both the Ender 3 and Ender 3 Neo fall somewhere in the middle. Some of the more complex parts, such as the hot end and base, arrive preassembled, while the rest of the parts ship in an unassembled state. Creality supplies a colorful instruction manual to assemble everything else.

For most users new to 3D printers, the assembly will likely take a couple of hours for either of the machines. If you've already assembled and used 3D printers before, you can set them up and get them working in less than an hour. There are no major differences in the amount of assembly required between the two printers.

Design

The Ender 3 Neo uses the same older monochrome screen found on the original Ender 3.

The Ender 3 and Ender 3 Neo are very similar in terms of overall design. They share the same Cartesian-XZ-head mechanical arrangement and 440 x 410 x 465 mm physical dimensions. The only difference in their appearance is the redesigned hot end housing on the Ender 3 Neo.

The Ender 3 Neo follows in the footsteps of its older brother with a distinctive PSU placement design on the side of the machine. This open-frame construction is not as attractive as the unibody enclosures on the more premium models, but we have not had any reliability issues with the power supplies on any Ender 3 printers and don’t feel this is a concern, beyond the appearance.

A potential weakness that the Ender 3 Neo has inherited from its predecessor is the single Z-axis lead screw. The absence of dual screws on both sides of the gantry leads to higher vibrations and unwanted movements during operation. However, we have found that this does not typically have a noticeable effect on print quality, especially at the size range of the Ender 3.

Improvements in the Ender 3 Neo

Creality has kept the best features of Ender 3 and built on them to create a more advanced 3D printer in the Ender 3 Neo. The upgrades are aimed at improving the usability and reliability of the printer, which are welcome improvements in a 3D printer aimed at beginners or enthusiasts wanting an additional machine. Here are the upgrades included in the Creality Ender 3 Neo.

CR Touch Auto Bed Leveling

The updated Ender 3 Neo hot end with the CR-touch auto bed leveling sensor (left side).

The CR touch auto bed leveling is a standard component across all Neo series 3D printers, including the Ender 3 Neo. It's a welcome addition and a bit of a surprise for an entry-level printer like the Ender 3 Neo. Similar to a BLTouch sensor, the CR touch probe analyzes the printing bed to detect any unevenness in it to automatically adjust the Z height during printing to compensate for an uneven bed.

Besides eliminating manual adjustments, which is a major convenience, auto leveling improves the precision of the first print layer. This directly affects the quality of the 3D prints from the machine, and reduces the possibility of print failures.

This is particularly a great feature for beginners, since manually levelling the bed can be a bit tricky to get used to and is a common cause for print failures if not done correctly.

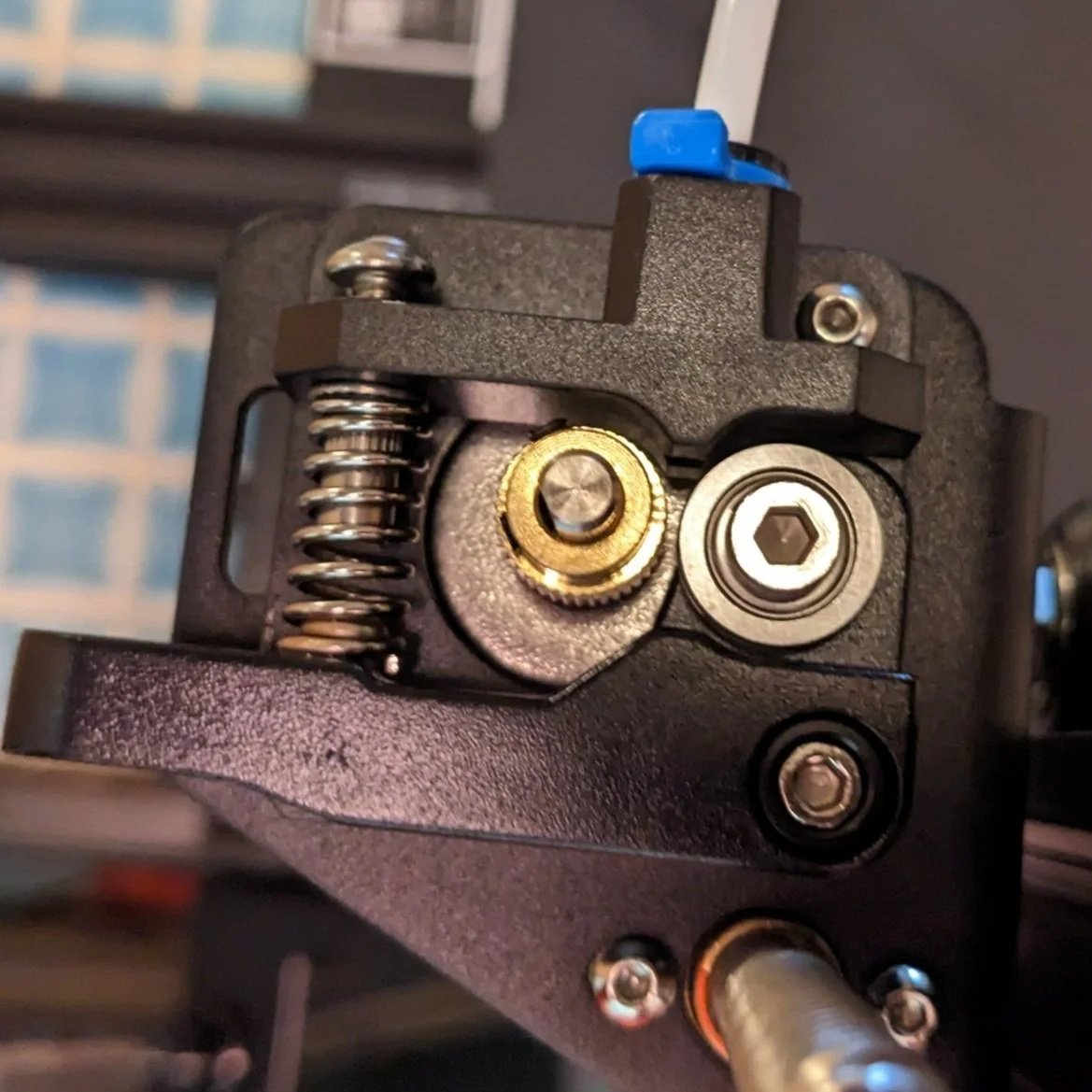

All-Metal Extruder

The Ender 3 Neo includes an all-metal extruder, which is a welcome upgrade. The brass gear does tend to wear over time, but can be easily upgraded to a steel gear, which won’t wear out.

While the Bowden extruder design on the Ender 3 Neo is very similar to the one on the Ender 3, we are pleased to see Creality replaced it with an all-metal version on the Ender 3 Neo.

The plastic extruder on the original Ender 3 was notoriously unreliable and prone to breakage. The constant tension from the springs would often break the extruder, and the design limited the spring tension that could be applied to the filament. A weak grip on the filament can lead to under-extrusion, resulting in poor quality 3D prints or total print failure.

The metal extruder on the Ender 3 Neo offers a more robust construction that won’t break after extended use, drastically improving the reliability of the extruder. It also allows you to tighten the spring tension significantly more, which causes the extruder to grip the filament more firmly and results in fewer jams and other extruder-related failures.

Carborundum Glass Bed

One of the most common complaints by Ender 3 users was the unreliable adhesion of its rigid textured film bed. Users often had difficulty removing the 3D prints from the printing bed. More importantly, the film bed was prone to damage, and replacing it was a big headache because the film was stuck onto the metal base with glue. In comparison, the Ender 3 Neo's carborundum tempered glass bed is superior in every way.

The glass base offers good adhesion at high temperatures, and at lower temperatures, the prints come off easily. It's robust, durable, and easily replaceable in case of faults or failures. It's definitely a welcome addition to the Ender 3 Neo.

Note: Users are recommended to clean the glass bed with a wet cloth after a dozen or so prints because tiny specks of printing materials tend to accumulate on it, which can reduce bed adhesion over time. The adhesion of the bed is completely restored by cleaning it with water.

Redesigned Hot End

The redesigned Ender 3 Neo heat sink helps reduce jamming.

The Ender 3 Neo introduces a redesigned hot end, which includes an updated enclosure and a redesigned heat sink on the hot end. The new heat sink provides more surface area and more space between the fins to make sure the cold side of the hot end stays cool. This is important to make sure that filament doesn’t start to melt sooner than intended, which can cause filament to jam in the hot end. While jams can be cleared pretty easily, they are inconvenient and cause the print to fail, so this is a welcome improvement.

Despite the updated hot end enclosure, the Ender 3 Neo uses a single cooling fan just like the earlier Ender 3, which only blows air on one side of the nozzle. The enclosure is symmetrical on the outside, which gives you the impression that it has dual fans on either sides. However, the machine has only one fan and it’s located on the right side. This part cooling system is able to handle most overhangs, but does not perform quite as well as the dual fan hot end of the Creality Ender 3 Max, or the larger single fan on the Creality Ender 3 S1 series.

Mainboard

The original Creality Ender 3 shipped with the v1.1.4 mainboard. After successive improvements, the latest Ender 3 models feature a V2.2.2 mainboard, which is still an older design. The Ender 3 Neo, on the other hand, features a 32-bit silent motherboard, but Creality has not revealed whether it's a silent version of the V2.2.2 or the V4.2.7, which comes as standard on all of the other Neo series printers. In any case, you’ll notice significantly less motor noise from the Ender 3 Neo, which is a major improvement if you have the 3D printer inside your house or near you while it’s running.

The Ender 3 Neo features the Resume Print feature, which protects your in-progress prints against unexpected power interruptions. The Resume Print feature lets you continue printing from where it was paused, due to a power outage or other reasons. If you experience an extended power outage, the print will probably still fail because the heat bed will cool down and release the printed model. But if you experience frequent brief power interruptions, this feature could be a very welcome addition.

The Verdict

The Creality Ender 3 Neo includes some of Creality’s more advanced features from their more expensive 3D printers, such as the carborundum bed, all-metal extruder, and auto bed leveling, which are features generally not found in this price segment. The Ender 3 was a great product for its time, and brought 3D printing to an entire new wave of hobbyists by offering an unprecedented value for the money. With the Ender 3 Neo, Creality is again changing the game by bringing these higher-end features down to an entry-level printer with a much lower price.

If you’re a new user, it’s worth noting that the Ender 3 Neo is not much more beginner-friendly than Ender 3. Both machines are equally complicated to assemble, and it will take some patience and time for users to get familiar with the devices. However, the inclusion of the auto bed leveling sensor ensures a consistent first layer, which can be a challenge when you’re first learning 3D printing. If you are looking for an easier assembly process, the Creality Ender 3 V2 Neo is worth looking at as a potential alternative to the Ender 3 Neo.

Overall, the Ender 3 Neo adds many nice to have improvements and while keeping the printer very budget friendly. For this reason, we think the Ender 3 Neo is well worth the additional cost over the original Ender 3, and we’re excited to see these improvements from Creality in their entry-level lineup.

If you’d like to compare other printers, take a look at our 3D Printer Comparison Tool. This tool lets you view multiple 3D printers side by side to easily compare features.