Choosing a Laser Cutter

If you’re interested in purchasing a laser cutter for your home or small business, you’ve probably discovered that there are a multitude of options that vary significantly in price. Laser cutters can start at $100 and go up to $10,000 or more, while ranging in size from small models that fit on a desk to large industrial machines that weigh hundreds of pounds. In this guide, we’ll help you determine what type of laser cutter fits your needs best and which models to consider for your laser cutter purchase.

Note: Creality Experts receives a commission for items you purchase from this page, at no additional cost to you. For more information, please see our affiliate link policy.

Is A Laser Cutter The Right Choice For You?

Laser cutters are capable of cutting and engraving materials in ways that no other tool can match, but they aren’t the right choice for every job. Before you purchase a laser cutter, consider what type of work you plan to do with it and make sure it will meet your needs. We will look at the following tools that address similar needs:

Laser cutters

CNC routers/mills

Cutting machines

What is a laser cutter best for?

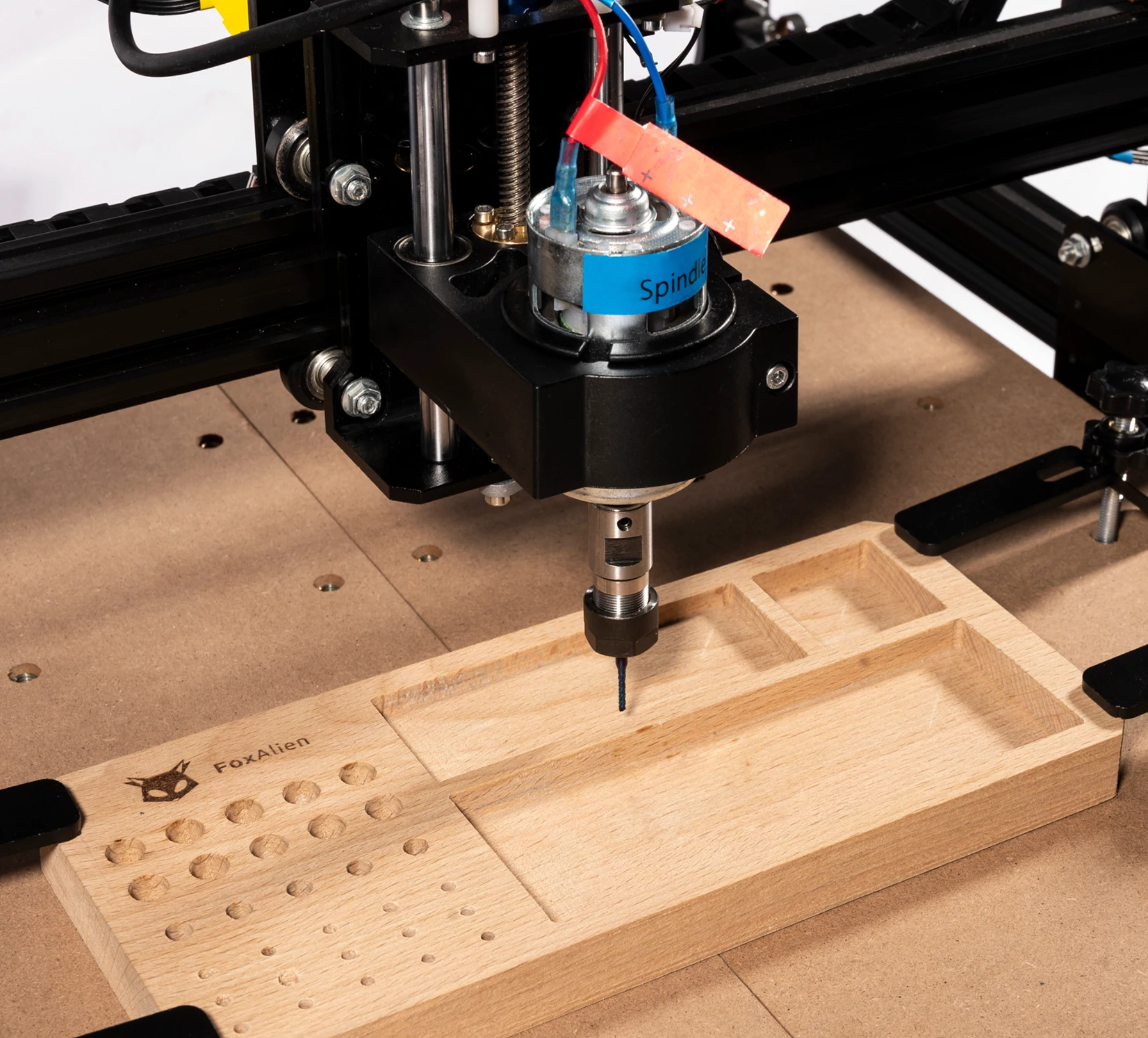

It’s best to think of a laser cutter as a two-dimensional machine. Although it’s possible to use a lower power setting on the laser so that it doesn’t burn all the way through the material, it’s difficult to control the depth of the cuts in a precise way. This means that it would be difficult to use a laser cutter to cut a 3D design into a material. A CNC router or mill would be better suited for that type of operation.

However, for two-dimensional cutting operations, a laser cutter can be a much more appealing choice than a CNC router or mill. Laser cutters are faster, quieter, and generate less mess. They also don’t wear down as many consumable parts such as cutting bits.

A CNC mill allows for more control over how deep you cut, but is slower and more messy than a laser cutter.

Laser cutters are able to cut very precise designs with little mess and are best for either through cuts or engraving.

Laser cutters are also ideal for engraving designs and images. They’re one of the best tools for engraving onto wood due to the precision of the laser and the pleasing appearance of burned wood. If you’re interested in this type of artwork, a laser cutter is the right choice for you.

What materials can a laser cutter cut and engrave?

Laser cutters are able to cut a wide range of materials, including paper, cardboard, leather, acrylic, and wood. For wood, it’s important to note that most consumer and prosumer laser cutters won’t be able to cut wood more than ¼” thick.

Most affordable laser cutters are not able to cut or engrave metal. You’ll need to spend more to get a fiber laser cutter if you need to cut metal. With cheaper cutters, you do have the option of burning off the top coating of metal to engrave a design. For example, you can engrave designs into anodized aluminum by using the laser to burn off the anodization coating. However, you will not be able to physically engrave designs deep into the metal itself.

One important note is that laser cutters cannot cut materials such as vinyl. Although the laser is capable of cutting through vinyl, this will release chlorine gas which can harm you as well as the machine. Opt for a Cricut (Amazon link) or Silhouette (Amazon link) if you’re primarily interested in cutting paper, vinyl, or leather, since these machines use a sharp blade instead of a laser.

What are the space requirements for a laser cutter?

A laser cutter like the Glowforge will require a large desk or work surface and should be near a window for proper ventilation.

Laser cutters vary in size from small desktop models to professional-grade machines that require a significant amount of shop space. For a general consumer or prosumer-grade machine, you’ll need an area at least the size of a large table or desk. You’ll also need a way to vent the laser cutter to the outdoors. The laser cutting process generates smoke and odors that you won’t want in your home or shop space, especially if you are cutting acrylic. Ventilation can be installed at home through an open window or more permanently through a venting solution similar to a dryer.

Most laser cutters have environmental requirements and will not function well in especially hot or cold temperatures. Some machines include a cooling system that can cool the laser tube even if the machine is located in a hot garage or shop, while other machines rely on ambient air for cooling and cannot handle those environments. Before purchasing a laser cutter, it’s wise to consider what space you have available and how it might affect which features you need in a machine (such as an integrated cooling system).

Types of Laser Cutters

Not all laser cutters are created equal. Your specific requirements will affect which type of laser cutter is best for you. There are three major types of laser cutters that we’re covering in this guide:

Diode lasers are typically the smallest, cheapest, and least powerful type of laser cutter. Although there are powerful diode lasers, most options in this category will be affordable but less capable than the other categories of laser cutter. A diode laser can be a great option for trying out the idea of owning a laser cutter. They’re well-suited for cutting materials such as paper and cardboard.

CO2 lasers are by far the most common option of laser cutter for home and small business use. They range in price from a few hundred dollars up to $10,000 or more and are capable of cutting wood and acrylic as well as thinner materials such as cardboard. CO2 lasers are much larger than diode lasers, which means they require more desk or floor space. They also require more aggressive cooling than diode lasers, which adds to the cost, size, and complexity of the machine.

Fiber lasers are the most expensive option and typically cost more than $10,000 just for an entry-level cutter. However, they offer much faster cutting speeds and are also capable of cutting through metal. Although fiber lasers are not a financial option for most hobby or small business users, they’re the only option if you need to cut metal.

Pricing

Your budget is one of the most important considerations in deciding which laser cutters are available to you. As with most tools, the more money you spend, the more capable and reliable your laser cutter is likely to be. However, that’s not to say you should stretch your budget to buy the most expensive machine possible. Cheaper machines are often smaller and can be easier for new users to approach.

Budget Machines $100-400

Low cost machines are a great way to try out a laser engraver, but they are not the best option if you are looking to cut wood.

In this price range, your options will be lower power cutters with a 20W power level, which will be able to cut paper, foam, cardboard, and very thin wood with multiple passes of the laser. They can also burn designs into wood, although they won’t be able to cut through wood in the same way as a more powerful machine. These machines are often small enough to fit on a desk. In some cases you can get a diode laser attachment for a 3D printer to reuse hardware you may already have. Additionally, since these lasers are lower power, they do not require a dedicated vent (though we still recommend keeping it in a well ventilated room or garage). It is also important to wear protective eyewear when near the machine, since it does not have an enclosure.

A diode laser cutter in this price range would be a great choice if you’re interested in the idea of laser cutting and want to learn the process in a hands-on way. This is how we started and it’s a great way to learn how to make laser cuttable designs and understand how the machine works. However, machines at this level are not particularly well-suited for business purposes due to their low power and small cutting size.

When shopping in this price range, be sure to look at the output power of the laser, which is typically a lower value than the input power.

Machines to look at:

ORTUR Laser Master (Check price on Amazon)

$400-2,000

OMTech laser cutters are made in China, but QA and support are provided within the USA. The K40 laser cutter is relatively easy to set up and capable of cutting wood.

There are a number of CO2 laser options in this price range. They’re almost all variants on a design called the K40 and are often shipped directly from sellers in China. These machines are powerful and are capable of producing excellent results, but often require significant tinkering and modifications for reliable and optimal performance. The sellers of these machines typically do not provide customer support after the sale and the quality control of the machines can be lacking compared with more expensive options.

The brand OMtech sells machines manufactured in China while performing quality checks for resale in the USA. They also provide post-sales support, which is difficult to get from China-based sellers. For these reasons, they are our preferred brand in this price range.

If you’re looking for a project and aren’t afraid of spending time tweaking your laser cutter for maximum performance and reliability, the K40 might be a great option for you. There is a thriving online community and a wide availability of upgrade parts, so you’ll be set for a fun hobby.

Machines to look at:

OMTech 40W K40 Laser Engraver (Check price on Amazon)

$2,000 - $5,000

Laser engravers like Glowforge come at a higher price, but are high quality machines which are easy to set up and use very quickly.

There are several exciting options in this price range for home and small business users. Several established manufacturers provide CO2 laser cutters in this price range. Consumer-oriented machines such as the Glowforge are designed to be easy to approach for a new user, while more business-focused machines such as the Full Spectrum Laser Muse have a higher learning curve but provide more capability.

If you’re seriously interested in owning a laser cutter for hobby or small business use, we highly recommend you consider a machine in this price range. This class of machine is generally going to be ready to use out of the box, and if you purchase from an established manufacturer, you’ll have access to superior customer support and service. These CO2 laser machines are capable of handling a wide range of cutting and engraving operations, making them more than sufficient for many laser cutter use cases.

Machines to look at:

$5,000+

Fiber lasers are the most expensive technology, but offer metal engraving capability.

In this price range, you’d be looking at a higher end machine suited for high-volume business use or industrial use. Companies such as Epilog make lasers that range from $5,000 up to $50,000 or more, placing them in a completely different class from the other lasers discussed in this article. Most hobby or small business users will not be considering a machine in this range.

Fiber lasers also fit into this price range. It’s possible to get a fiber laser for around $6,000, and if you want to cut or engrave metal, you’ll need a fiber laser. Fortunately, there are additional advantages to purchasing machines in this price range. Typically, they will be more reliable than less expensive machines, and the manufacturers generally will provide more hands-on support for any issues that may come up.

Machines to look at:

Next Steps: Research Specific Machines

Although it can be overwhelming to choose the right laser cutter, the key is to narrow down your choices by considering your needs and budget. Once you’ve narrowed down exactly what types of materials you want to use, what type of cutting or engraving you want to do, and what your budget is, you’ll be in a much better position to make an informed choice about your laser cutter purchase.

Your next step from here should be to research specific machines that fit your needs and budget. We encourage you to use the products listed here as a first step in your learning.