How to Print With Nylon Filament on Creality 3D Printers

If you are printing functional parts that need to be durable, nylon is a great choice because it is stronger than standard filament materials such as ABS. Since it has some flexibility while still remaining a rigid material, nylon can absorb a lot of force without breaking and has exceptional impact resistance. If you own a Creality 3D printer such as an Ender 3 or CR-10, you may be asking: can I print with nylon on my 3D printer, or is it only possible on commercial-grade 3D printers?

Fortunately, printing with nylon is definitely possible with Creality 3D printers, however it is not an easy material to work with. Overcoming the challenges of working with nylon will require you to either make modifications to your 3D printer, or use special blends that make it possible to print without upgrades. In this article, we will explain the challenges and show you how to overcome them so you can print nylon on your Creality 3D printer.

Note: Creality Experts receives a commission for items you purchase from this page, at no additional cost to you. For more information, please see our affiliate link policy.

Nylon has a high melting temperature

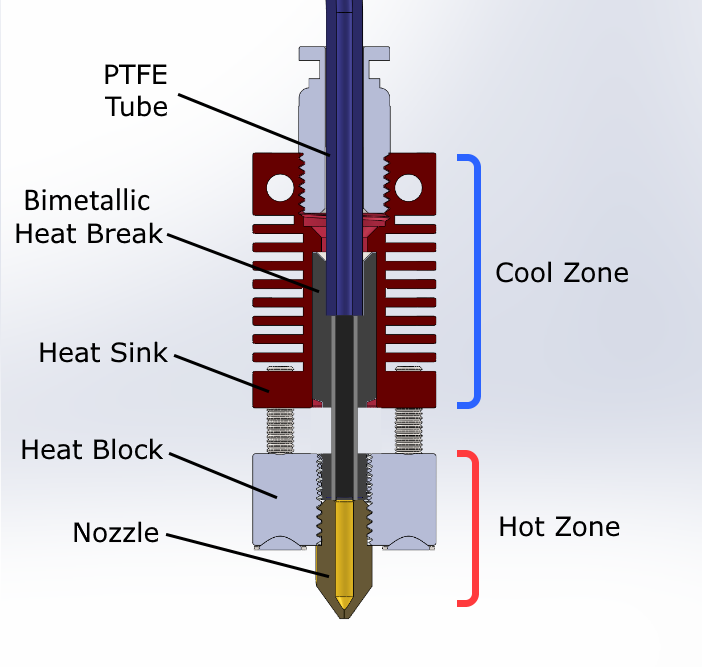

For pure nylon filaments, you’ll need to heat your hot end to at least 270 °C or above to effectively print with it, which is substantially hotter than other materials. Stock Creality 3D printers can only reach 260 °C since they use PTFE tubing to route the filament to the nozzle, which starts to melt above 260 °C. In order to go hotter, you’ll need to upgrade to an all-metal or Bimetallic hot end. We recommend installing the Slice Engineering Bimetallic heat break, which you can learn more about in our bimetallic heat break installation guide.

On the standard hot end, the PTFE tubing extends all the way to the nozzle and is exposed to the hot temperature of the heat block.

With a bimetalli heat break, the PTFE is fully within the cool zone, allowing you to heat the nozzle to far higher temperature without damaging the PTFE tube.

You’ll also update the firmware of your printer to override the maximum temperature limit, which defaults to 260° C. The process for doing this varies depending on your 3D printer, and is beyond the scope of this guide. That said, everything you need to rebuild and update the printer firmware is available online for free.

Fortunately, there are nylon blends that can be printed well at temperatures at or below 260 °C, which will allow you to print nylon with the standard firmware that your printer already has. Even if you go with one of these options, we recommend upgrading to a bimetallic heat break if you plan to print nylon often, since the high temperatures will cause additional wear to the PTFE tubing in the standard hot end. We have tried a few of these blends and will take a look at them later in the article.

Nylon is susceptible to warping

Since nylon shrinks as it cools, it is important to make sure it is printed in a heated environment to slow down the cooling speed. A 3D printer enclosure is critical for success with nylon if you are printing larger parts. Nylon blends mitigate this somewhat, but we still recommend using an enclosure for nylon printing. You can see one suitable 3D printer enclosure on Amazon here.

Nylon absorbs moisture very quickly

Nylon is notorious for absorbing ambient humidity much more quickly than other filaments, and typically must be dried right before use. If not dry, the surface quality and strength of your parts will suffer. You can purchase a filament drybox enclosure to keep filament dry to aid with this issue. We do not recommend using a home oven for this purpose since it is very easy to overheat and melt the filament spool, causing a fire hazard. However, a food dehydrator large enough to fit filament is an effective way to dry it. You can view our recommended filament drybox on Amazon here.

Printing with Standard Nylon

If your printer is upgraded to be capable of higher print temperatures, you can print with a pure nylon.

Recommendation: Overture Nylon (view on Amazon) is a great option with an affordable price tag compared to other nylon options.

Our Recommended Print Settings for Standard Nylon Filament

Nozzle Temperature: 270-280 °C

This will require upgrading your printer to an all-metal hot end or equivalent, such as the bimetallic heat break which can be easily installed on most Creality 3D printers. You will also need to update the firmware to allow temperatures above 260 °C.

A thin layer of PVA glue (a standard glue stick) on a glass print bed provides the best bed adhesion for nylon.

Bed Temperature: 55 °C

Interestingly, an extremely hot bed does not help with nylon adhesion like it does with ABS. Nylon has a glass transition temperature of 70 °C, so any hotter than this will increase warping. We recommend using a PVA glue stick on a glass print bed for the best results with nylon.

Maximum Printing Speed: 30 mm/s

For Bowden extruder setups, Nylon should be printed slowly since it does have some flex similar to TPU, though it is rigid enough to allow retraction. For direct drive, you can print somewhat faster and with more retraction.

Maximum Cooling Fan Speed: No fan

Like ABS, cooling cannot be used with nylon since it needs to cool as slowly as possible to reduce warping and delamination.

Recommended Nylon Blends

If you are looking to print with nylon without substantial upgrades, there are a number of nylon blends available which provide many of the benefits of nylon without requiring firmware upgrades to print at higher temperatures. We have two recommended options for nylon blends.

Recommendation: NylonX from MatterHackers

Matterhackers NylonX is a Nylon blend that is infused with carbon fiber to provide additional tensile strength. This blend also includes additives which allow the material to be printed at 250C, which is within the range of stock Creality printers. While this filament is quite expensive, it is a great option for end use parts since it is both easier to print with and stronger than standard nylon.

The carbon fiber in this blend makes it more abrasive, so it will wear down your nozzle more quickly. You may want to use a hardened steel nozzle when printing with it, or be willing to replace your nozzle more frequently.

Recommended Print Settings for NylonX

Nozzle Temperature: 255-260 °C

Bed Temperature: 65 °C, with PVA glue stick on glass

Printing Speed: 30 mm/s

Maximum Cooling Fan Speed: No fan

Recommendation: Taulman Nylon 230

If you would prefer to print nylon at cooler temperatures and do not want to upgrade the hot end of your printer, we recommend Taulman 230 from Matterhackers. It’s also available from Amazon here. Taulman 230 is a nylon blend that can be printed effectively at 230 °C. This nylon filament is still difficult to print, requiring that you keep it dry and print it in an enclosure, but can be used with a stock Creality 3D printer. Since this material is a blend, it is not quite as strong as pure nylon filaments, but the trade-off can be worth it for the cooler printing temperature.

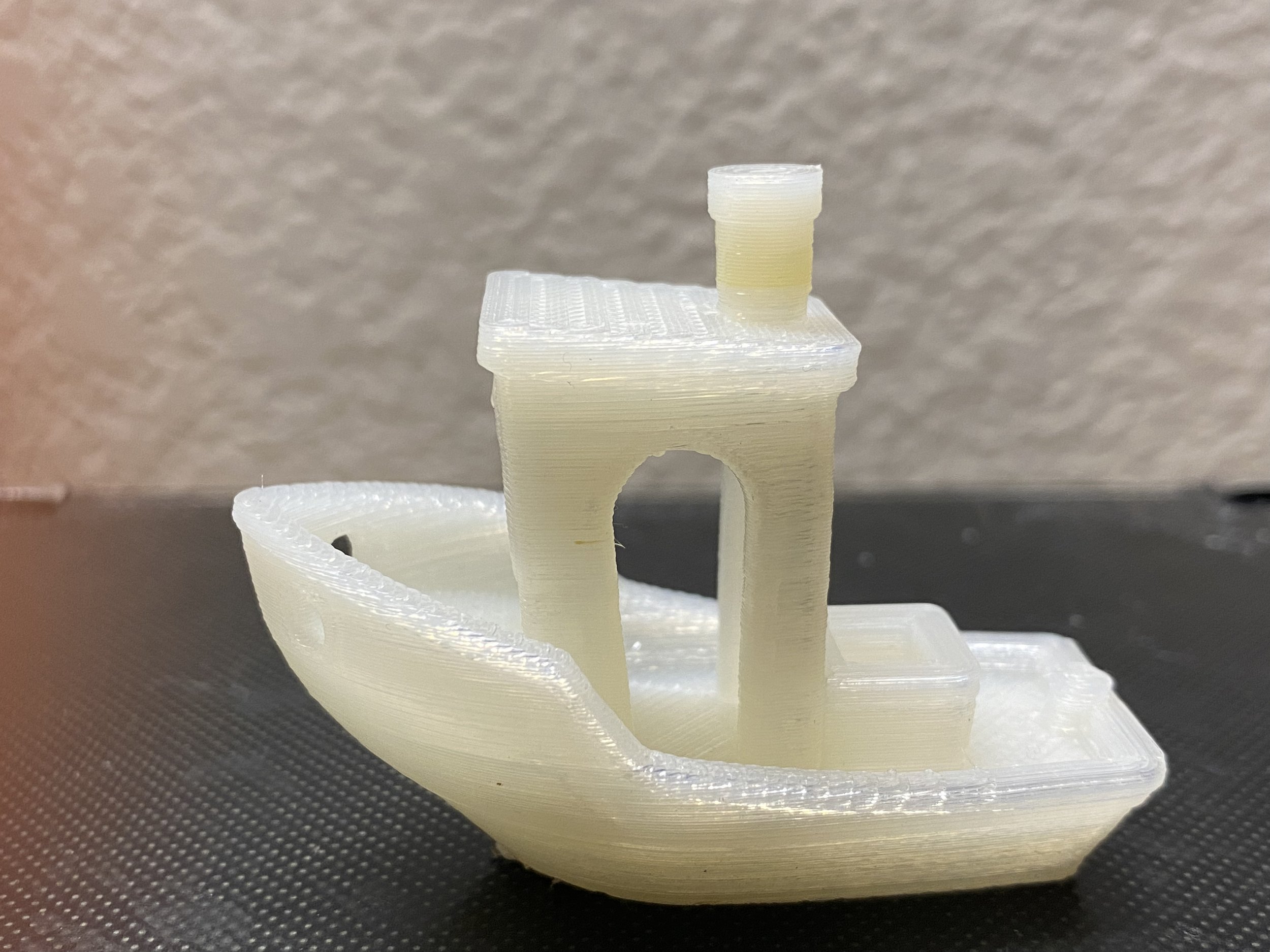

When we tested this filament, we found printing it a bit hotter helped to improve the layer adhesion. The surface finish and overhang performance wasn’t quite as good as the NylonX, but we were still happy with the results for a nylon print on a stock Creality 3D printer.

Our settings for Taulman 230

Nozzle Temperature: 235-240 °C

Bed Temperature: 45 °C, with PVA glue stick on glass

Printing Speed: 30 mm/s

Maximum Cooling Fan Speed: No fan

Next Steps

If you are interested in printing with either pure nylon or nylon blends, we definitely suggest looking into upgrading to a bimetallic heat break, since this upgrade will also help keep your hot end problem free with other standard materials as well. Take a look at our bimetallic heat break guide for more information on how it helps, and how to install it.

If you’re interested in printing other types of filament on your Creality 3D printer, including filament that is easier to print with, check out our complete filament printing guide.