Comparing the Creality Ender 3 V3 SE vs Anycubic Kobra Neo

Note: Creality Experts receives a commission for items you purchase from this page, at no additional cost to you. For more information, please see our affiliate link policy.

The Creality Ender 3 V3 SE and Anycubic Kobra Neo are two compelling entry-level 3D printers with many similarities, but a few important differences. In this article, we'll compare the features of these two 3D printers to help you understand the differences between them and decide which one is better for your needs.

Vs.

Shared Features Between The Creality Ender 3 V3 SE and Anycubic Kobra Neo

The Ender 3 V3 SE and Kobra Neo are similar in many ways, but they do differ slightly even on features that appear to be the same. For each of these features, we'll point out the areas where the printers differ.

Direct Drive Extruder and Hot End

Both printers include a direct drive extruder, which is a huge improvement to these entry-level models. Direct drive extruders are more reliable and can print flexible filament much more easily than Bowden extruders.

The Ender 3 V3 SE and Kobra Neo both include a direct drive extruder, which is a meaningful advantage over the Bowden extruders found on many other entry-level 3D printers. Compared to Bowden extruders, direct drive extruders are more reliable, can print faster, and can more easily print flexible filaments such as TPU. The overall design of the extruder and hot end is similar between the machines, although the Ender 3 V3 SE can print faster, which we'll cover in the Differences section below.

The direct drive extruder is really one of the biggest features that both the Ender 3 V3 SE and Kobra Neo bring to the entry-level 3D printer market, and it’s enough of an improvement to make either of these printers a better value than many other similarly-priced machines.

Both printers can print with a maximum hot end temperature of 260° C, which allows them to print all standard filament types, such as PLA, ABS, PETG, and TPU.

Automatic Bed Leveling

Both printers include automatic bed leveling, but the Ender 3 V3 SE has an extra strain-based sensor for setting the Z offset.

Both 3D printers include an automatic bed leveling system, which probes the bed surface in a grid pattern to compensate for any variation in bed height. This improves the quality of prints and usability of the printer, making it a welcome addition at this price point. The printers do use different sensors for the automatic bed leveling--the Ender 3 V3 SE uses a CR-Touch sensor which physically touches the bed, while the Kobra Neo uses an inductive sensor that detects the bed using a magnetic field. We've had a few bad experiences with inductive sensors, but our testing of the inductive sensor on the older Anycubic Kobra proved it to be reliable, so we have no conerns about the bed leveling sensor on either printer and consider them to be equivalent.

The Ender 3 V3 SE does include an additional sensor not found on the Kobra Neo, which is a strain gauge sensor for setting the Z offset. Most automatic bed leveling systems require the user to manually set the Z offset, which is the vertical spacing between the tip of the sensor probe and the nozzle. To simplify this process, the Ender 3 V3 SE includes a strain gauge sensor under the print bed, allowing it to automatically set this offset by detecting when the nozzle touches the bed. It's not hard to set the offset manually, but this is a nice added feature that makes the Ender 3 V3 SE a little easier to use. We discuss this feature more in our review of the Ender 3 V3 SE.

Build Volume and Size

Both the Creality Ender 3 V3 SE and Anycubic Kobra Neo offer a 220 x 220 x 250 mm (8.6 x 8.6 x 9.8 in) build volume. This is a standard build volume for 3D printers at this price point.

The printers are also similar in physical size, but the Ender 3 V3 SE has a smaller desk footprint:

Creality Ender 3 V3 SE: 490 x 364 x 349mm (19.29 x 14.33 x 13.74 in)

Anycubic Kobra Neo: 490 x 445 x 443mm (19.29 x 17.52 x 17.44 in)

The Ender 3 V3 SE is almost 3 inches smaller in width and depth, which may not seem significant, but can be a factor when trying to fit the printer onto a crowded desk or workbench. However, the printers are the same height, and both mount the filament spool on the top of the printer, which adds to the height requirements for your printing space.

Setup Process

Both printers require some assembly, but arrive almost fully assembled—a big improvement over previous entry-level 3D printers.

Both printers require some assembly, but arrive mostly assembled and only require a few simple steps to complete the process. We're pleased that entry-level 3D printers no longer require an hour or more of assembly. The calibration and setup process for the printers is similar, with the Ender 3 V3 SE having a slight edge due to the strain gauge Z offset sensor discussed previously.

Power Loss Recovery and Filament Runout

The Ender 3 V3 SE and Kobra Neo both include power loss recovery, which allows you to resume a print if your printer loses power during the printing process. However, neither printer comes standard with a filament runout sensor. You do have the option of purchasing the sensor as an add-on for either machine if you want to add that feature.

Neither printer has a touchscreen, but both feature a color LCD that is modern and easier to use than older monochrome or text-based displays.

We don't typically find these features to be beneficial because either a power loss or filament runout will cause the print bed to cool down. This releases the print from the bed, making it impossible to resume printing in the same location later. We can imagine the power loss recovery being useful if you live in an area that frequently experiences brief power interruptions, however.

Controller and Display

Both the Ender 3 V3 SE and Kobra Neo include a color display, but both printers are controlled with a dial and button rather than including a touchscreen. The Ender 3 V3 SE's screen is a bit more modern and appears to display more colors, but this is a minor difference. We don't have any concerns about the lack of a touchscreen on either model, and the screens used on these printers are far beyond the older monochrome LCDs or text-based displays found on many other 3D printers.

Next, we’ll look at the differences between these printers.

Differences Between The Creality Ender 3 V3 SE and Anycubic Kobra Neo

In this section, we'll cover the areas where these two 3D printers are different, and explain how each of these features may affect your experience with each machine.

Printing Speed

One of the biggest differences between the Creality Ender 3 V3 SE and the Anycubic Kobra Neo is their maximum print speed. The Ender 3 V3 SE advertises a maximum print speed of 250 mm/s, and we've printed at up to 175 mm/s reliably on our machine. On the other hand, the Kobra Neo advertises a "typical" print speed of 60 mm/s and a maximum of 100 mm/s, with a note indiciating that the 100 mm/s is a lab result with a specific 3D model. While we haven't personally tested the print speed on a Kobra Neo, we'd read this claim as a reliable print speed of 60 mm/s.

The Kobra Neo comes with a PEI-coated bed, which we feel is superior to the PC-coated bed on the Ender 3 V3 SE.

This is a substantial difference in print speed, and will directly affect how long 3D prints take on each machine. It's worth pointing out, though, that many other 3D printers on the market offer speeds at or below the Kobra Neo's 60 mm/s. So the Kobra Neo isn't necessarily slow, but it can't match the speed of the Ender 3 V3 SE.

Bed Material

The Ender 3 V3 SE includes a PC-coated flexible steel bed, while the Kobra Neo includes a PEI-coated flexible steel bed. Both of these materials are great for layer adhesion, but we prefer PEI beds for their ease in removing prints and resistance to damage compared to PC. The Kobra Neo definitely wins out on this point.

However, on both printers the bed surface attaches magnetically to the printer, making it easy to swap out. You can purchase a PEI-coated bed on Amazon for the Ender 3 V3 SE and easily install it on that printer if desired.

Mechanical Stability and Adjustment

The Creality Ender 3 V3 SE and Anycubic Kobra Neo both use Cartesian motion systems and have an overall similar physical design, but have a few meaningful differences that affect the stability and adjustment of the printers.

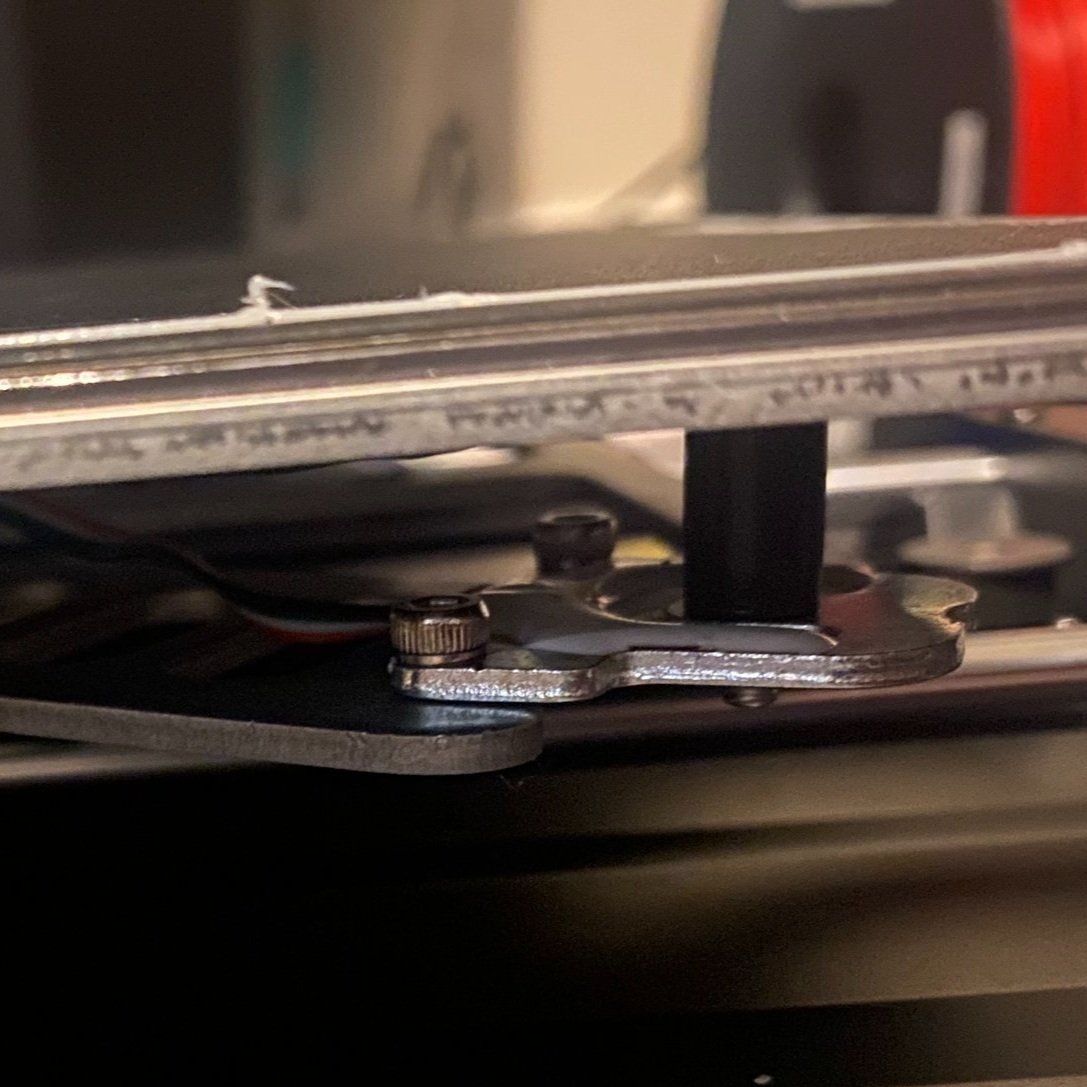

The Ender 3 V3 SE uses two Z lead screws, although both are driven by a single motor.

For the Z axis, the Kobra Neo uses a single Z leadscrew, which lifts the gantry from only one side. In contrast, the Ender 3 V3 SE has two Z leadscrews to lift the gantry evenly from both sides. Both leadscrews are driven by a single motor, with a belt connecting them to transfer the rotation from one side to the other. This should improve the stability of the Ender 3 V3 SE, especially when printing taller objects.

Additionally, the Ender 3 V3 SE uses linear rods to guide the Y axis, rather than the pulleys used by the Kobra Neo. While the pulley guide system is a proven design used on many 3D printers, linear rails are a clear stability upgrade and often found on higher-end machines.

On the other hand, the Kobra Neo includes belt tension adjustment knobs on the X and Y belts, allowing you to easily adjust the belt tension without any tools. The Ender 3 V3 SE requires you to use a hex wrench to adjust the belt tension. While we don't find ourselves adjusting the belt tension often on these machines, the hand-turn knobs on the Kobra Neo are more user-friendly.

While these are not major differences, the Ender 3 V3 SE does have a more sophisticated mechanical design that should improve stability and reduce resonance artifacts during printing. This is a likely contributing factor to the higher print speeds offered on the Ender 3 V3 SE.

The Verdict

The Creality Ender 3 V3 SE and Anycubic Kobra Neo offer many similar features, but we think the Ender 3 V3 SE wins out, primarily due to its print speed advantage. The speed of the Ender 3 V3 SE, backed up by its more stable mechanical design, will directly translate to faster prints, which reduces one of the biggest annoyances in 3D printing.

The Kobra Neo does offer a better bed surface, so if you want to match that feature with the Ender 3 V3 SE, you'll need to budget a bit extra for an upgraded PEI bed. In most other respects, the Kobra either matches the features of the Ender 3 V3 SE or falls slightly short.

At the time of this writing, the MSRP of the two printers is very similar, which makes us feel that the Creality Ender 3 V3 SE is the clear best choice. However, if you can find the Anycubic Kobra Neo at a substantial discount, it's still a solid entry-level 3D printer with an impressive feature set.

Click here to view the Creality Ender 3 V3 SE on Amazon.

Click here to view the Anycubic Kobra Neo on Amazon.

Here is a recap of the two printers to sum up their similarities and differences:

If you’d like to compare other printers, take a look at our 3D Printer Comparison Tool. This tool lets you view multiple 3D printers side by side to easily compare features.