Anycubic Kobra vs Creality Ender 3 S1

In this article, we will compare the affordable Anycubic Kobra with the Creality Ender 3 S1, a printer with many of the same features and one that we already recommend. The Kobra comes with a substantially lower price tag, but is there more to the story?

We gravitate toward Creality 3D printers since we are most familiar with them, but the low price and impressive feature set of the Anycubic Kobra caught our attention. Most notably, it includes automatic bed leveling and a direct drive extruder, which are typically found on more expensive premium 3D printers such as the Prusa MK3 or Creality CR-10 Smart Pro. Creality’s closest 3D printer to the Kobra is the Ender 3 S1, which also offers these more premium features at an affordable price; though it is still around $100 more than the Anycubic Kobra.

After testing this printer, we did notice a few important differences worth considering when looking at the Kobra, which we will cover in more detail in this article. Before reading on, take a minute to compare the basic features of each printer below.

Note: Creality Experts receives a commission for items you purchase from this page, at no additional cost to you. For more information, please see our affiliate link policy.

Vs.

Shared Features

Lets start with the features that the Anycubic Kobra (Amazon link) shares with the Creality Ender 3 S1 (Amazon link).

Material Capabilities

Both the Ender 3 S1 and Kobra use a standard PTFE-lined hot end, which maxes out at 260C. This is sufficient for common materials including PLA, ABS, PETG, or TPU. More exotic filaments like nylon require hotter temperatures and cannot be printed on either machine, though Creality offers the Ender 3 S1 Pro which includes an all-metal hot end capable of these temperatures (we compare the Ender 3 S1 and S1 Pro here).

The direct drive extruders on these 3D printers enable you to print flexible materials (such as TPU) much more easily. Bowden extruders can print flexible materials, but must do so very slowly and are prone to jamming, so a direct drive extruder is definitely an important feature if you are looking to print flexibles. If you aren’t familiar with the differences between Bowden and direct drive extruders, you can read more about the differences in our Extruders overview article.

Chassis Style / Physical Size

Though they are made by different companies, the Kobra and Ender 3 S1 have a similar chassis design, based on the Prusa i3 style with a side mounted screen. The construction of the Kobra uses a bit more plastic than the Ender 3 S1, but this does not have any functional effect on the printer. Both printers have a top-mounted spool holder which works well with the direct drive extruder, which loads from the top. This means that you won’t need additional space to the side of the printer, however it can make it more difficult to fit in a shelving unit where there is limited vertical space.

Print Quality

Despite the price difference, both of these 3D printers are capable of great quality prints out of the box, which is becoming more common now that FDM 3D printing technology is more mature. One difference we do often see between different machines is part cooling, which impacts how well the printer can print overhanging parts without negatively impacting quality. The Ender 3 S1 has the edge here, with a larger part cooling fan mounted on the front of the hot end. The Anycubic Kobra uses a slightly smaller fan which doesn’t produce quite as much airflow. That said, both printers performed well on our overhang test print up to a 75 degree overhang.

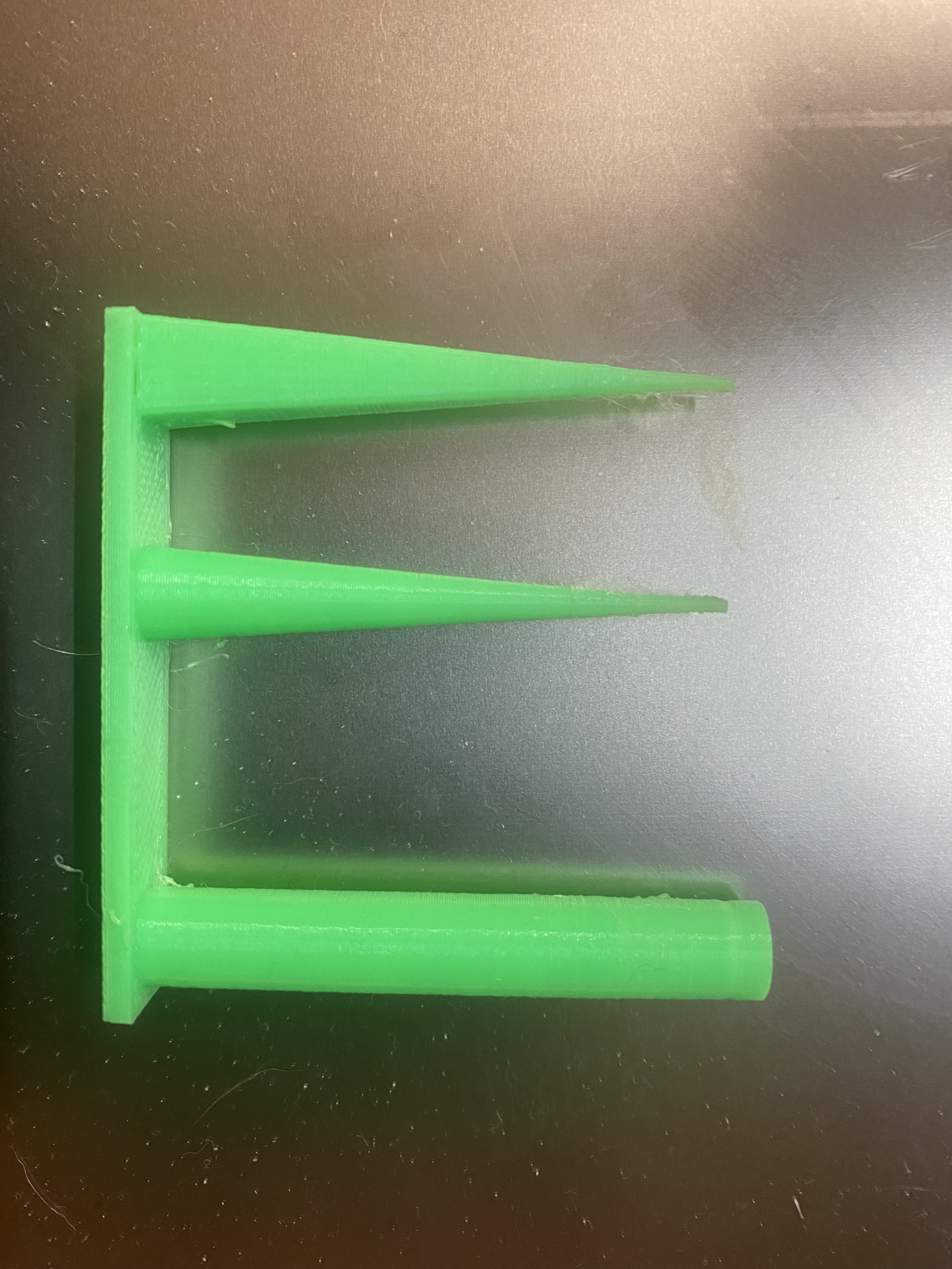

Kobra Sample Prints

The parts below from the Kobra show its quality out of the box, and has minimal stringing even with low retraction settings, which is typical of direct drive extruders.

While we were able to get good prints from the Kobra, it was hard to find information on settings for the Kobra online. This is understandable since it is a newer machine, and Anyubic has not been in the FDM market nearly as long as Creality so there is less community support. We ended up having success with settings similar to the Prusa MK3, but there is definitely not a strong community yet around this printer as compared to Creality, so we had to do a bit more experimentation to find settings that worked well.

Ender 3 S1 Sample Prints

The prints below from the Ender 3 S1 show similarly high quality results, with good details, good overhang performance, and minimal stringing.

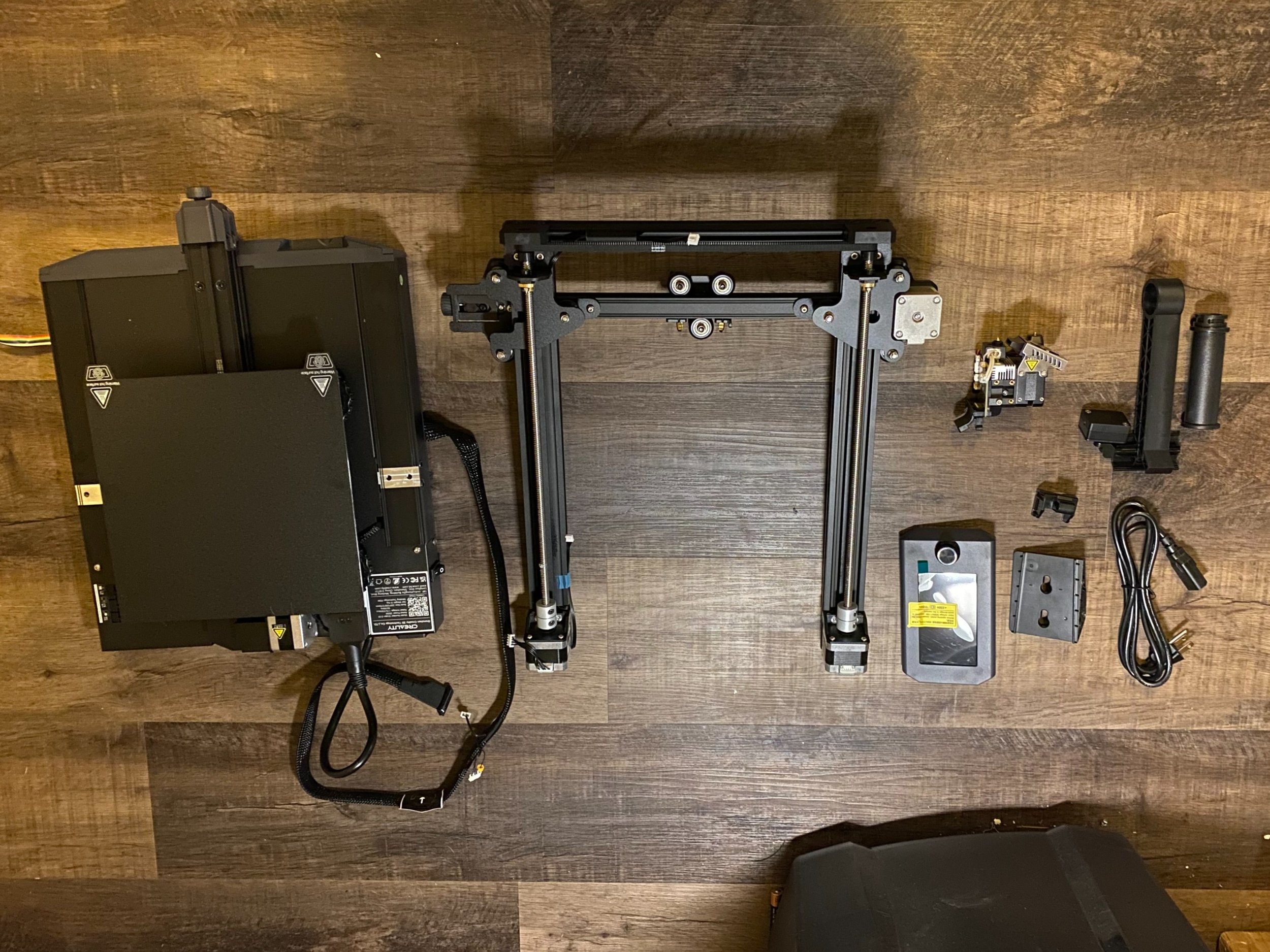

Assembly

Both the Creality Ender 3 S1 and the Anycubic Kobra are mostly assembled out of the box. The entire gantry for both printers comes fully assembled, so you’ll only be assembling a few parts, and you can complete it in around 15 minutes. The process involves connecting the parts with provided screws and tools, then attaching the cabling by matching up the provided labeling. The only difference in the process is that the extruder of the Ender 3 S1 is not attached to the printer, but overall the assembly process for both printers is very similar and easy to do.

We noticed when assembling the Kobra that some of the eccentric nuts to make the bed and Z axis rigid were loose, but this seems to be by design since the assembly manual included instructions to tighten these nuts appropriately. We were happy to see since Creality also uses eccentric nuts to control the tension of the pulleys, but on the downside, Creality doesn’t mention how to adjust them in their manual.

The Anycubic Kobra before assembly.

The Creality Ender 3 S1 before assembly.

Build Volume

Both printers have the same bed size of 220mm x 220mm, which is a fairly standard size capable of printing most parts. The prints differ in height, but only slightly: the Ender 3 S1 has a bit more height at 270mm vs the Kobra’s 250mm, but this will not make much difference in most cases, so we don’t think the size is a determining factor between these printers. If you are looking for a larger direct drive printer, Creality provides more options, such as the Ender 3 S1 Plus (Amazon link), which offers a 300 x 300mm bed with the same direct drive extruder as the Ender 3 S1. Anycubic also makes printers in this size range, such as the Kobra Max, but that printer uses a different Bowden style extruder.

Reliability

We printed large numbers of parts with both 3D printers and were happy with their consistency. The parts above were printed on the Creality Ender 3 S1.

To test the reliability of the Anycubic Kobra and Creality Ender 3 S1, we used both printers for a few months to print parts for our 3D printing business. We were happy with the consistent results we saw from both printers. Neither one required any repairs and were able to able to reliably crank out parts that were identical in size and quality.

We had some adhesion issues with the stock print beds of both of these printers, and recommend upgrading both, but we will talk more about that in the print bed section later.

We noticed that the Kobra exhibited a surprisingly large amount of wear on the rubber wheels that the bed and print head use to roll along the aluminum extrusion. This hasn’t caused issues yet, but you may need to replace them sooner than you would on other 3D printers.

Other Shared Features

Both printers have many modern features that are nice to have on any 3D printer.

Power recovery - Allows you to resume a print if the printer shuts off due to a power failure.

Updated Mainboard with Silent Stepper Drivers - Older 3D printers such as the Creality CR-10 produced a song-like sound when printing due to the frequencies of the motors moving. Newer electronics prevent this issue, making the printer substantially quieter. The only sound you will hear is from the fans, and is much easier to ignore.

Filament Runout Sensor. If your printer runs out of filament, the printer will pause and beep to let you know, allowing you to reload it and start again. Unfortunately, we’ve noticed that the bed heater also turns off when this happens. If you are not able to restart the print within about 10 minutes, the part will often detach from the bed, preventing a successful recovery.

Next, we’ll look at the differences between the two 3D printers.

Differences between the Creality Ender 3 S1 and Anycubic Kobra

Auto Bed Leveling

While both of these printers have auto bed leveling, they use different technologies for the sensors. The Creality Ender 3 S1 uses a Creality CR-touch probe, which uses a physical sensor to measure the position of the bed. On the other hand, the Anycubic Kobra uses an induction-based sensor which uses a magnetic field to sense the print bed. We were pleased with both of these sensors, and we were largely able to not think about bed leveling on each 3D printer, which is the ultimate goal of automatic bed leveling.

The Ender 3 S1 CR-touch sensor uses a metal probe which senses the bed’s position by touching it.

The Kobra uses an inductive probe (in orange) which has no moving parts, and measures proximity to the metal in the print bed.

We were wary of inductive bed leveling sensors due to a bad experience with one on the first generation of the Creality CR-10S Pro being inaccurate, but the Anycubic Kobra’s inductive sensor is similar to the one on the Prusa MK3S+, and is very reliable. The Kobra does not include leveling knobs, which we find a bit odd since it can be helpful for tuning the bed, but it did not cause us any issues. One downside of the inductive probes is that they require metal to work, so thicker glass beds are not an option with this sensor. However, other magnetic bed materials, such as smooth PEI, can be used with no issue

The Ender 3 S1’s CR-touch sensor fixes the main deficiency of the more well-known BL-touch leveling sensor, which is that it is easy to break the leveling probe when a print failure occurs. The CR-touch sensor uses a metal probe, and we have not had any issues with it. Since the sensor is based on physical touch, you can use any bed material, including glass, without any recalibration.

Overall, both printers performed equally well here, but the Ender 3 S1 does provide more bed material flexibility, such as if you prefer to use a glass bed.

Bed Material

Both printers include a flexible steel magnetic build surface, which you can remove after the print completes to help detach the completed part. However, the coating on the bed materials differ.

The Kobra uses a textured PEI coating, which we had good results with at first, but eventually started to have issues with adhesion. This is not unusual for PEI beds, and typically a quick clean with isopropyl alcohol or acetone can restore the bed. However, when we tried this with the stock bed it didn’t really help, and we also noticed the painted logo on the bed dissolved, making us think it was not the correct way to clean it. At this point, we replaced it with our preferred material, the smooth PEI bed. It may be possible to clean the stock bed with another cleaner, but we weren’t able to find any information about alternative methods for cleaning the bed.

The Ender 3 S1 uses a PC coating, which provides very good adhesion, but does not release the parts when the bed cools like PEI does. This makes removing parts more difficult, and we actually had a couple parts stick enough to remove small pieces of the coating after printing many parts. We ended up also upgrading this bed to smooth PEI, since these beds provide good adhesion and also release the parts when cooled.

Z Axis Drive System

The Ender 3 S1 includes a dual Z axis drive system, which ensures that the extruder stays at a consistant height as it moves from the left to the right side of the printer. The Kobra uses a single drive system, and the right side of the extruder gantry moves freely. The dual Z axis system is often touted as a major feature which improves print quality, but we have never seen a significant difference in quality due to the second Z drive, especially on printers at this size scale, so we do not consider this to be a significant difference between the machines.

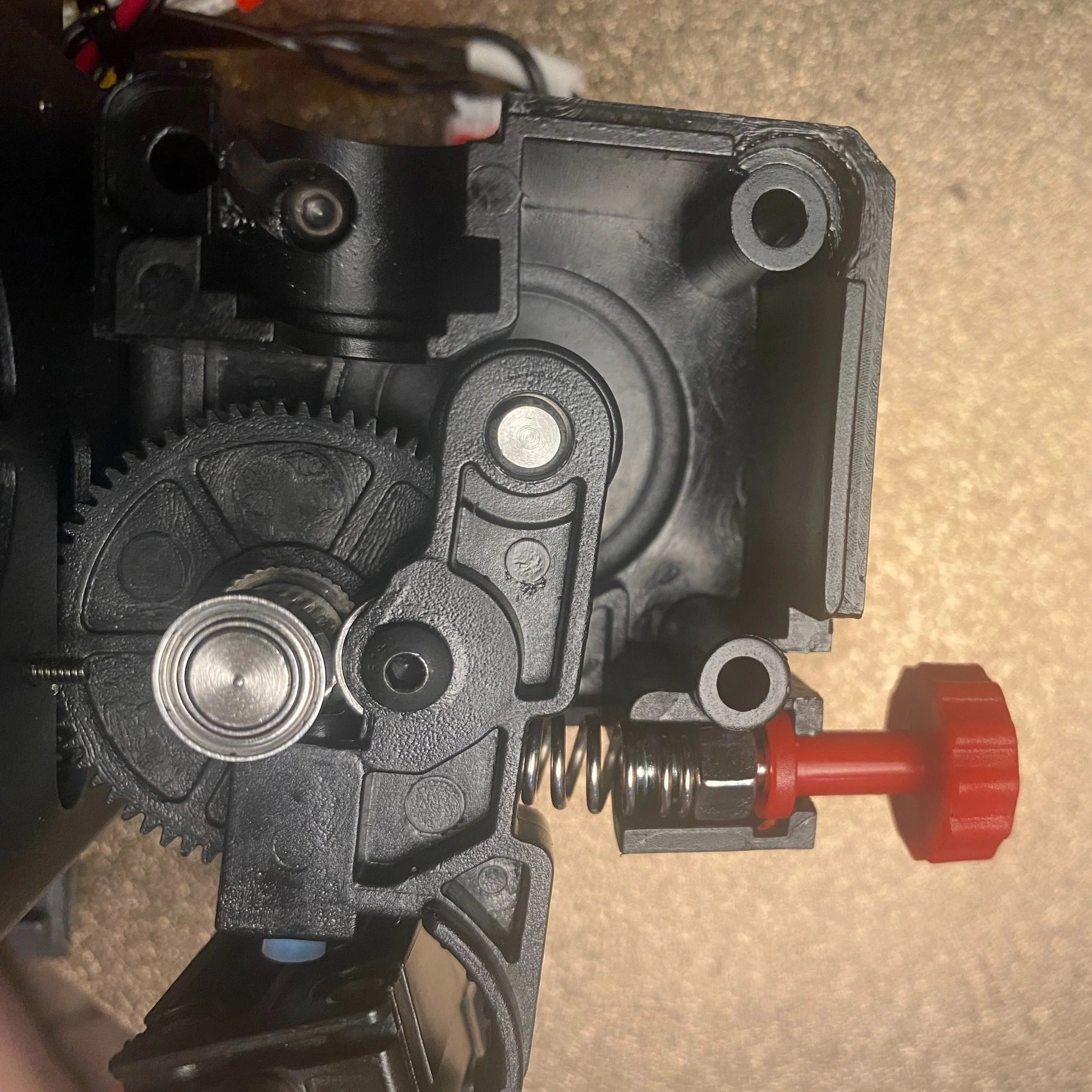

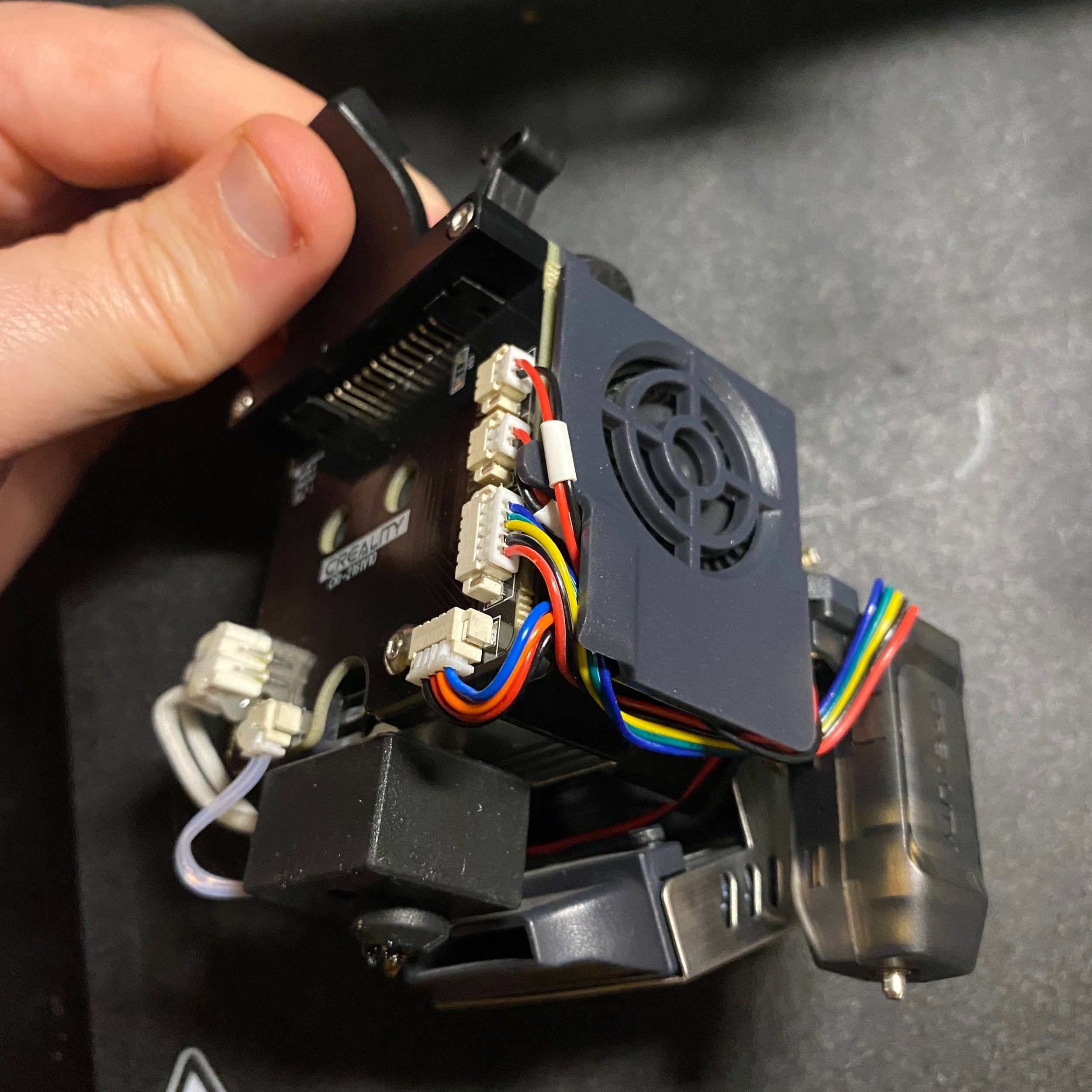

Extruder Construction & Part Cooling

While both machines use a direct drive extruder, the construction is different between the two machines. The Creality Sprite extruder has a dual gear design, which ensures good grip on the filament, and uses a single front-mounted fan for part cooling. We typically prefer designs with two cooling fans, but the fan on the Sprite extruder is mounted at an angle and oriented close to the nozzle, which helps increase airflow and deliver good overhang printing performance. You can see more details about the Sprite extruder in our Sprite Extruder teardown article.

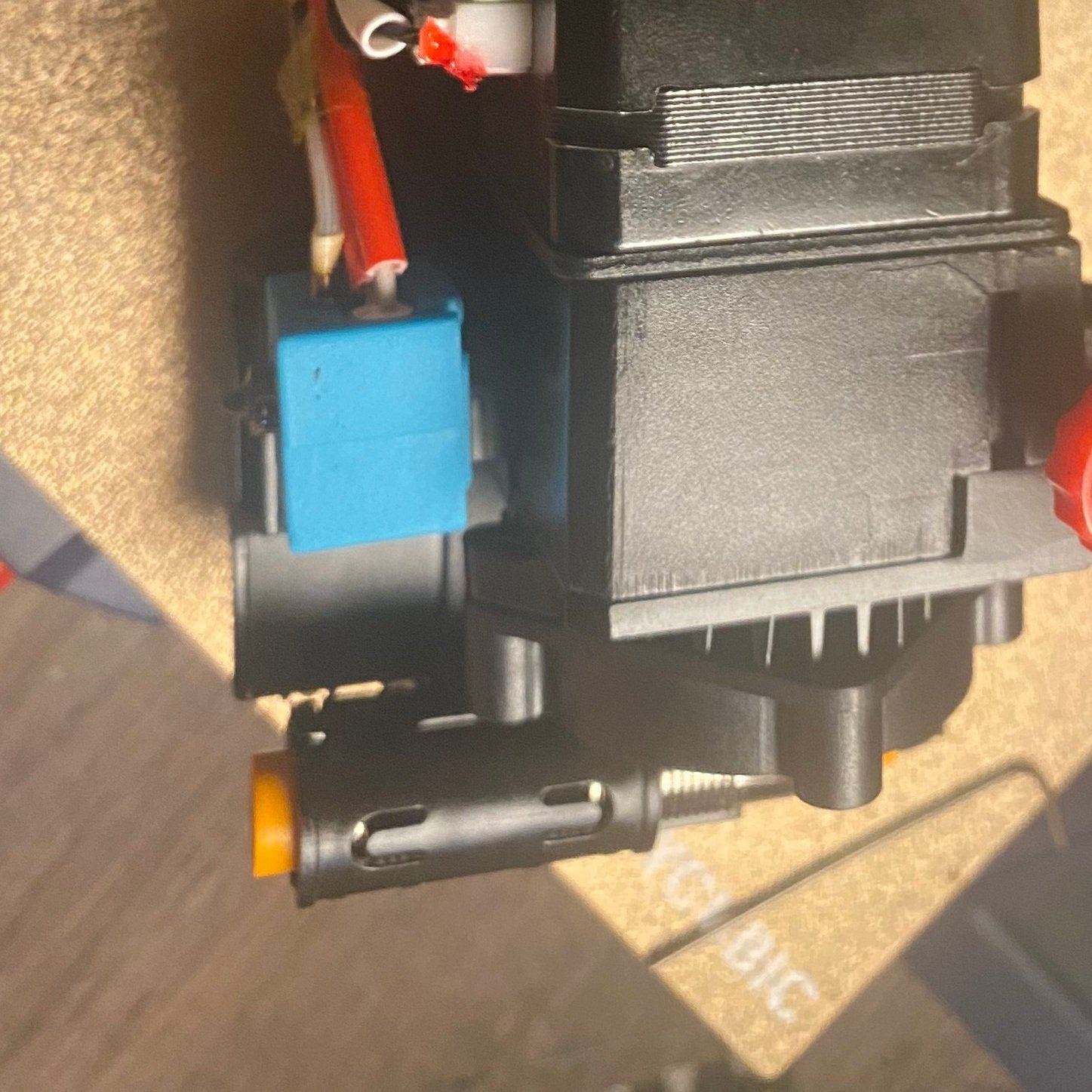

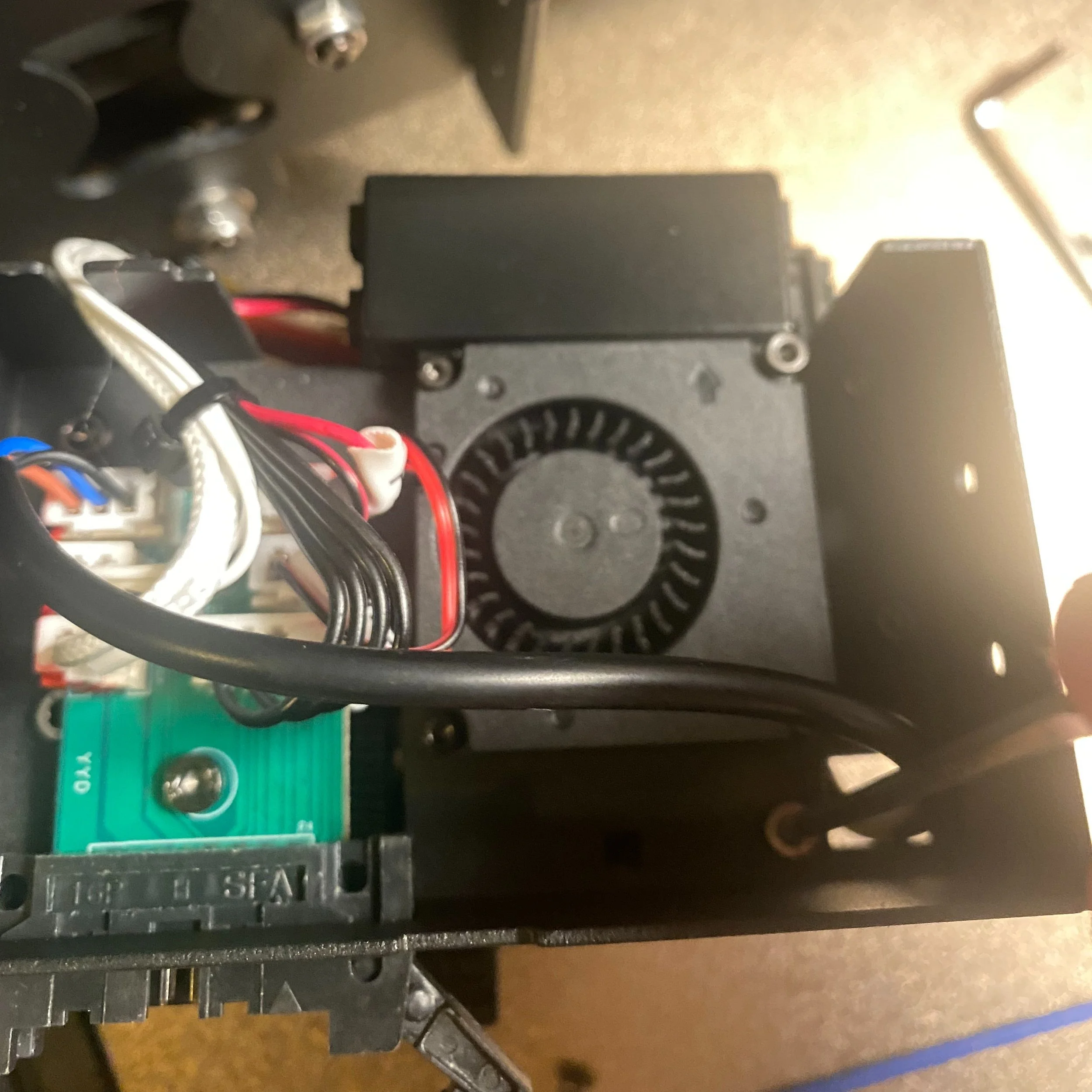

The Anycubic Kobra extruder is fully enclosed, and is substantially larger in size, making it more difficult to observe the print as it is progressing. This can make it a bit harder to tell when failures occur, but it isn’t a major deficiency. Taking the extruder apart, we noticed it uses a single gear design, but we haven’t had any issues with weak extrusion so far. It uses a rear-mounted cooling fan, which doesn’t cool quite as well since it relies on a duct to route the air to the nozzle and isn’t positioned as close to the nozzle as the Sprite’s fan. Additionally, the fan is inside the hot end enclosure, which limits airflow and uses hotter ambient air. Despite this, the cooling performance of the Anycubic design is good, but the Sprite performs better on more extreme overhangs.

The Creality Sprite extruder uses a dual gear mechanism to provide improved filament grip.

The Anycubic Kobra extruder uses a single gear extruder with an idler pulley.

The Sprite cooling fan has great airflow and is oriented close to the nozzle.

The Kobra cooling fan is mounted further away from the nozzle and is inside the extruder housing (extruder was removed for this photo).

Software Setup

Anycubic is traditionally more well known for their Resin 3D printers, but has recently made a move into the filament printer space with their Kobra and Vyper series machines. On the other hand, Creality has been producing filament 3D printers for a longer time, and has built a larger community around their printers. This became apparent in our testing of the two 3D printers, since with the Anycubic machine we had some difficulty finding 3D printing profiles for common slicers like Cura and Prusaslicer online. Typically, 3D printers include a preconfigured slicer profile with recommended settings, but no profiles were included with the Kobra. We were able to get good prints from the Kobra after some experimentation with a few important settings like retraction, print temperature, and print speed. However, for a new user it could be a bit challenging to get everything configured correctly without some trial and error.

The Creality Ender 3 S1 has a profile available in Prusaslicer, and also includes the Creality slicer software, which has a profile for the printer as well. We recommend sticking with Prusaslicer or Cura since they have more widespread community support. A quick online search will yield multiple options for Cura profiles for the Ender 3 S1.

Usability & Convenience

We were impressed to see that the Kobra included a touch screen, which is rare to find on any printer in its price range. The touch screen interface is easy to use and definitely a step up from the knob-based control scheme on the Ender 3 S1. The Ender 3 S1 Pro, a more premium printer in Creality’s lineup, has a touch screen—but it’s in the $500 price range, substantially more than the Anycubic Kobra. We noticed that the screen has a white background and is fairly bright to look at, and doesn’t have any settings to dim it, but this was not a major issue and overall we prefer it to the interface of the Ender 3 S1.

The Verdict

Overall, we feel that the impressive feature set of the Anycubic Kobra make it a great buy at its low price point, but we do give the Creality Ender 3 S1 the edge in terms of overall reliability and print performance due to its improved cooling fan setup. The getting started experience for the Ender 3 S1 was also easier, since we were able to find pre-created profiles online for the common slicers, but we were impressed with the clear assembly guide of the Kobra.

Based on this, if price is a big factor in your decision, and direct drive and auto bed leveling are important features for you, the Anycubic Kobra (Amazon link) is one of the best choices on the market right now. If price is less of a concern, and you are looking for a printer that will be easier to set up and require a bit less tinkering, the Creality Ender 3 S1 (Amazon link) is likely a better choice for you.

We encourage you to take a closer look at both 3D printers now that you have a better idea about the similarities and differences. You can review the important stats in the comparison tale below:

If you’d like to compare other printers, take a look at our 3D Printer Comparison Tool. This tool lets you view multiple 3D printers side by side to easily compare features.