Creality Ender 3 Series - Complete Guide

The Creality Ender 3 printers have earned a reputation as great 3D printers at a low price point. However, Creality has expanded the Ender 3 product line over the years, evolving the original Ender 3 design as well as adding higher-end options. We still think these are some of the best 3D printers you can buy, especially at their low price point. But as Creality has added more models in the Ender 3 line, it’s gotten more confusing to determine which one best fits your needs.

In this article, we will look more closely at each of the Ender 3 series printers in order of price to give you a better idea what you are getting with each of these machines. We’ll make recommendations based on what we have found from using these printers ourselves. After reading this article, our hope is that you’ll be able to choose which Creality Ender 3 model is best for your needs and budget.

Note: Creality Experts receives a commission for items you purchase from this page, at no additional cost to you. For more information, please see our affiliate link policy.

History of the Ender 3 Series

The Ender 3 series signature is the side mounted LCD screen

In March 2018, Creality released the first 3D printer of the Ender 3 Series - aptly named the Ender 3. This printer was aimed at offering all the baseline 3D printing capability you need, and nothing more, at a very affordable price. There were few other 3D printers at such a low price point at this time, and the Ender 3 quickly became known as one of the best budget 3D printers available. The signature shared by all printers in the Ender 3 series is the side-mounted LCD, which offers a great balance between clunky control boxes, and more expensive unibody designs, allowing for a compact and portable printer at low cost.

Creality saw a winning formula with the Ender 3, and has since released many variations on the original Ender 3, progressively offering more features while keeping the price point fairly low. Later the same year, they released the Ender 3 Pro, followed by the Ender 3 V2 in 2020 which is now a standard in the 3D printing community.

In 2021, Creality took a different approach with the Ender 3 S1 series, which offered substantially more features, but with a much higher price that takes these machines out of the budget category. The next year, in mid 2022, Creality released the Ender 3 V2 Neo, a move back toward the budget market with a much lower price point than the S1 series.

In 2023, Creality released the new Ender 3 V3 series, including the Ender 3 V3 SE and KE. These printers further push the envelope, offering features of the S1 series (and a few extras too) at the price point of the Neo series.

3D Printers in the Ender 3 Series

The Original Ender 3

The Ender 3 ships in many parts to reduce the size of the packaging. Assembly will typically take about an hour to complete.

The original Ender 3 is purely a budget 3D printer, and offers no frills at a low price. It has a minimal enclosure, which exposes both the power supply and the LCD screen. The machine also is shipped in many smaller pieces to lower freight costs, meaning a more involved assembly process which takes about an hour to complete.

However, despite the low cost, the print quality of the Ender 3 is impressive. It also has a build volume of 220 x 220 x 250 mm, which is a bit larger than the standard 200mm cube of many 3D printers on the market. The extended Z height is convenient to allow larger parts while not increasing the amount of required desk space.

The Ender 3 is capable of printing all common materials, such as PLA, PETG, and ABS - the hot end can reach up to 260 C, and the print bed can reach up to 100 C, which is the standard for most of the Ender 3 Series.

The Ender 3 chassis has some differences between the models, but all have an integrated screen which is mounted to the side of the printer, which is convenient in making the printer easy to transport, and reducing the footprint of required desk space. This is in contrast to the CR-10 series printers, which use a separate control box that makes the printer more difficult to transport.

The Ender 3 uses a simple pulley-based system for the 3 axes of motion, which can sometimes require adjustment when assembling the machine. This is a much lower-cost motion system than more premium linear rails, and can match the quality of linear rails when properly adjusted by tightening special nuts on the pulleys. This system is used on every printer in the Ender 3 series and many other Creality printers since it is simple and effective.

If budget is your main concern and you are willing to live without the modern features that the newer versions of the Ender 3 series include, the Ender 3 is a compelling option.

Ender 3 Pro

The Ender 3 Pro was released soon after the original Ender 3, and includes a few small updates, including a more reliable Meanwell power supply, a removable magnetic build plate, and a thicker base beam.

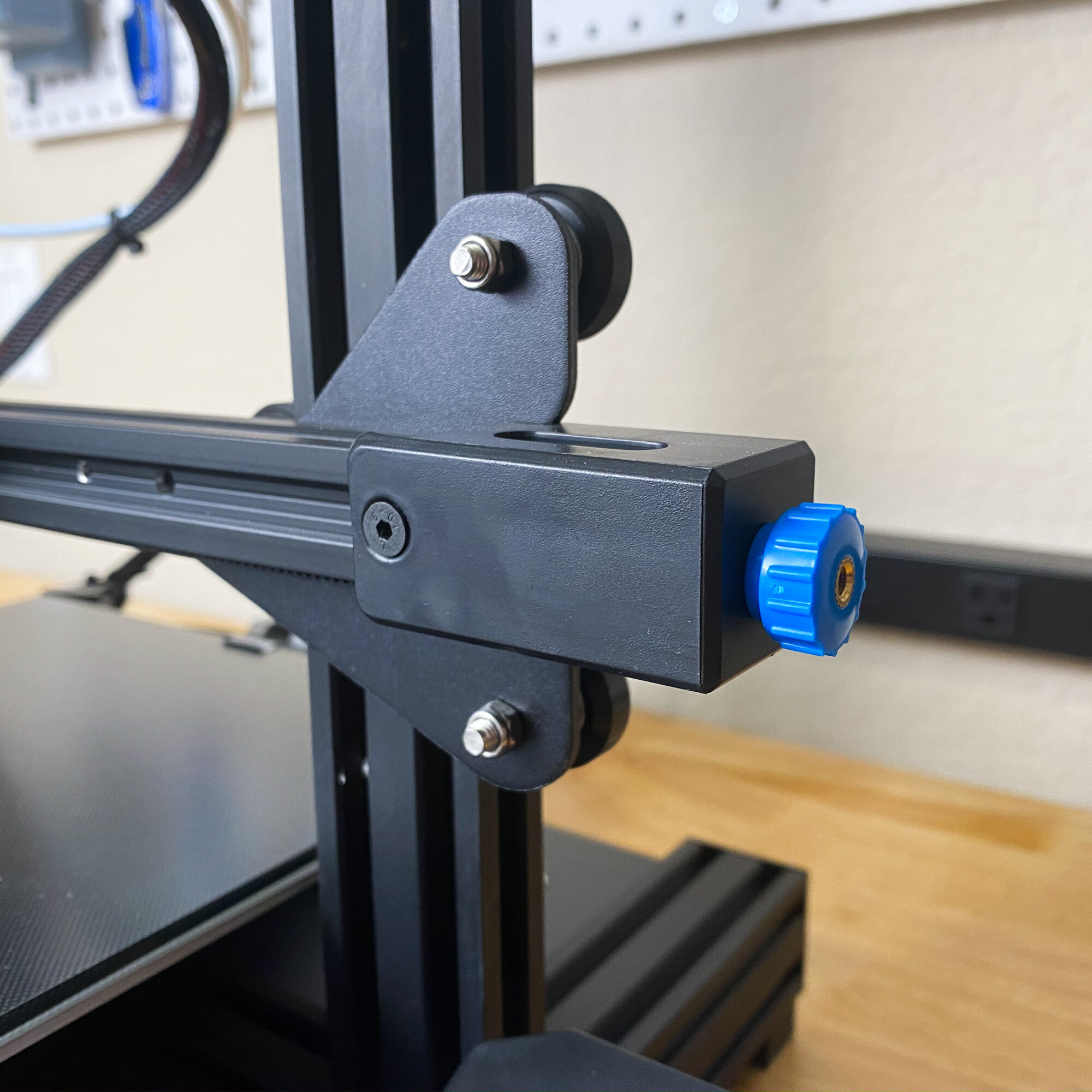

The Ender 3 Pro adds minor improvements, such as a larger central beam and larger leveling knobs

Aside from these features, it is largely the same as the original Ender 3. We won’t spend much time discussing this printer because we don’t feel like these updates are worth the additional cost - the Ender 3 is a better choice to save money, while the newer models offer a more compelling feature set.

Ender 3 V2

The 2020 release of the Ender 3 V2 was a significant improvement to the Ender 3 series, adding a number of nice-to-have modern features to the printer:

Built in belt tensioners on the Ender 3 V2 allow you to very easily tighten the belts if needed.

Glass Print Bed - Glass is a very reliable surface to print on, since it is not easily damaged by incidental contact with the nozzle or stubborn parts. It also releases parts when it cools, making them easy to remove. In contrast, the previous Ender 3 beds were made of different materials which can be difficult to remove parts from.

Meanwell Power Supply - These power supplies are known for their reliability, and we have seen this ourselves; we have replaced a number of power supplies on older printers like CR-10s, but have yet to have a Meanwell fail after years of continuous printing.

Power Outage Recovery - This feature allows you to resume a print where it left off after a power flicker, which can be a lifesaver for long prints.

The Ender 3 V2 Screen is larger and has a more modern user interface. Both screens are operated using the knob below the screen.

(image from https://www.creality3dofficial.com/)

Additionally, Creality added a number of cosmetic and usability updates to make the printer design cleaner, including hiding the power supply, adding a new larger LCD interface, adding an improved mainboard that makes the motion system nearly silent. The new interface is easier to use, but one thing we noticed is that it looks like it would be a touch screen, but it is still controlled using a separate knob. This caused us some confusion when we originally tested the printer. The Ender 3 V2 also made some changes to the chassis to provide space for a utility drawer to store the tools that are included with the printer.

The core features remain the same, including the same extruder and hot end (though the hot end enclosure has a new appearance, it is functionally the same), and the pulley-driven motion system. However, it adds built in tensioning knobs which make it much easier to ensure the belts that drive the X and Y axis are tight and do not slip.

For these reasons, the Ender 3 V2 was our top recommended budget printer for quite a long time, but this recommendation has recently changed due to the release of the Ender 3 V2 Neo.

Ender 3 Neo

In 2022, Creality released the Ender 3 Neo. You may have noticed that this printer actually came out later than the Ender 3 S1 series. However, we chose to cover these out of release order because we feel that this printer is the true successor to the Ender 3 series, since it still remains in the budget price point.

We were pleased to see the addition of automatic bed leveling (ABL) as a standard feature. While it is possible to upgrade previous Ender 3 series printers with ABL, it is a more involved upgrade, and the sensor itself typically retails for around $50, making it a fairly expensive upgrade as well

This upgrade alone was enough for us to recommend this printer over the Ender 3 V2, but it includes some other features we were happy to see as well:

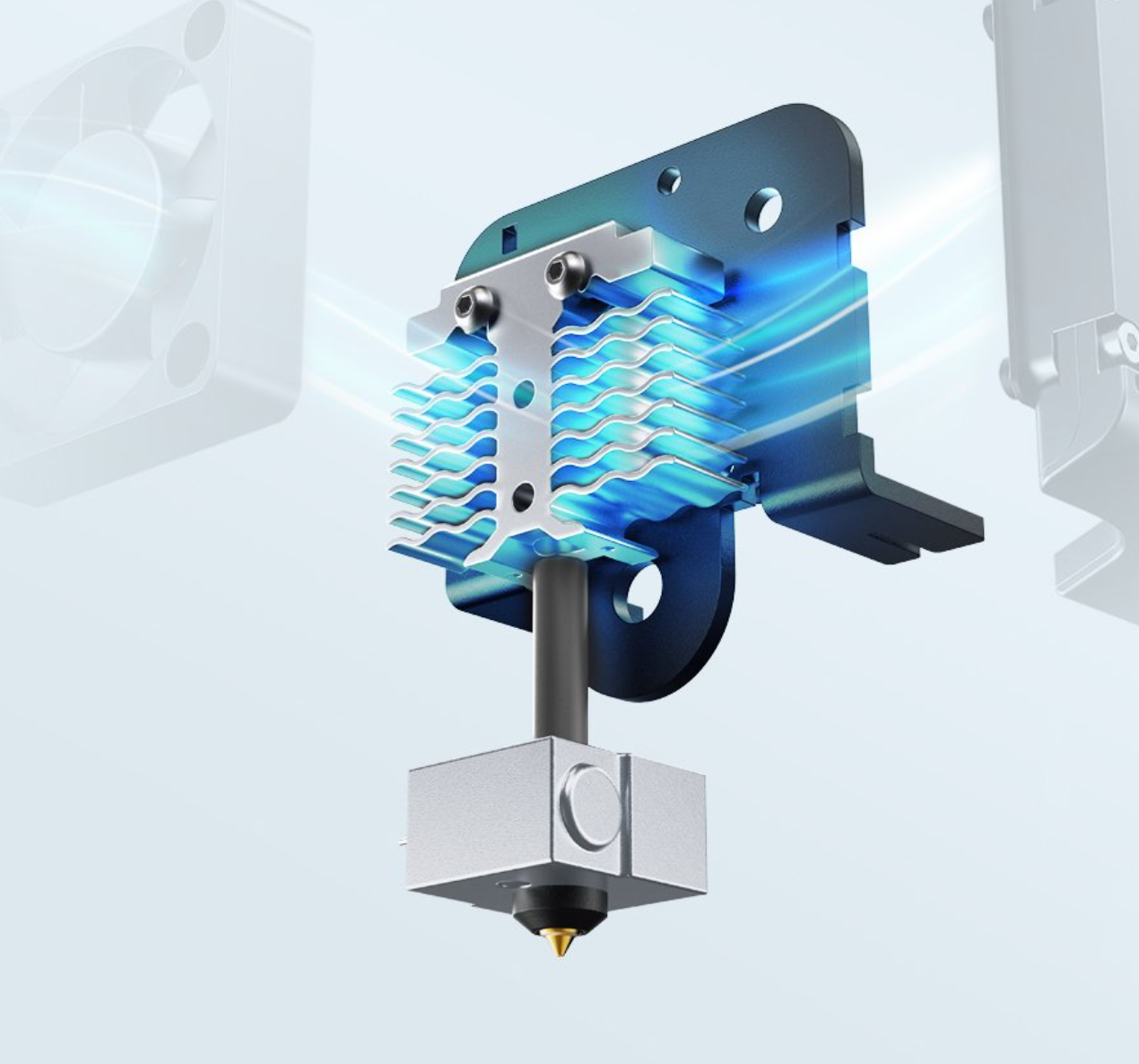

The Ender 3 Neo has a new heat sink to improve the cooling of the cold side of the hot-end

All-Metal Extruder - The plastic extruder on previous Ender 3 series printers was a common failure point, and we always recommended upgrading this to a metal version, so seeing this as a standard feature was very welcome.

Carborundum build surface - This coated glass build plate is one of our favorite materials to print on because parts stick very well when heated, but can be removed easily after the bed cools. Unlike standard glass beds, you won’t need to apply hairspray to get good adhesion, you just need to clean it with a wet cloth every 10-15 prints

While the Ender 3 Neo’s hot end enclosure has a new appearance, the hardware has not changed significantly from the Ender 3 V2. The only update is a new heat sink with more surface area to improve heat dissipation and reduce jamming. Aside from the new heat sink, it uses the standard Creality Bowden hot end with a single side cooling fan.

The Ender 3 Neo does take a couple steps back from the Ender 3 V2, including a move back to the exposed power supply and older style LCD. However, this printer actually has a lower price than the Ender 3 V2, making it a very compelling choice if you are looking to get the most useful features on a budget.

Ender 3 V2 Neo

The Ender 3 V2 Neo is the more premium printer in the Neo series, including the nicer LCD from the Ender 3 V2 and the more sleek chassis with a concealed power supply. Like the Ender 3 Neo, it includes Auto bed leveling and an all metal extruder. However, there are a couple differences to note:

Easy Assembly - This is a very welcome update to the Ender 3 V2 Neo. Unlike its predecessors, the Ender 3 Neo V2 ships with the entire upper section of the printer assembled, making the assembly process much easier than the Ender 3 V2 and Ender 3 Neo. We estimate that it will take about 10-15 minutes from unboxing to your first test print.

Magnetic PC Build Surface - We feel like this bed is actually a bit of a step down from the carborundum bed of the Ender 3 Neo. It is much more robust than the matte magnetic bed of the Ender 3 Pro and offers very good adhesion especially with smaller parts. However, parts are harder to remove than a glass bed, even when removing the bed and bending it We also have noticed that this bed material is more susceptible to damage than a glass bed, so you’ll need to be more careful to level the printer correctly before printing.

While the Ender 3 V2 Neo’s hot end enclosure has a new appearance, the hardware has not changed from the Ender 3 V2. It uses the standard Creality Bowden hot end with a single side cooling fan. Oddly, the new heat sink used on the Ender 3 Neo is not present on this printer.

The magnetic PC steel bed is durable, and can be removed and bent to make it easy to remove completed parts.

The updated LCD includes a convenient preview image of the print, but otherwise is very similar to the Ender 3 V2.

The Entire gantry portion of the printer comes preassembled, making the assembly process much easier.

A more minor improvement is an Updated LCD Interface - Though still not a touch screen, Creality updated the UI for their LCD to add a preview image to the UI, making it easy to be sure you are printing the object you expect. However, aside from that, the interface is largely the same as the Ender 3 V2.

Overall, the ~$100 increase in cost over the Ender 3 Neo is a bit more than we would like for the added features, but with a sleeker appearance and easier assembly, the Ender 3 V2 is a good compromise between the Ender 3 Neo and the Ender 3 S1 series, which we will cover next.

Ender 3 S1

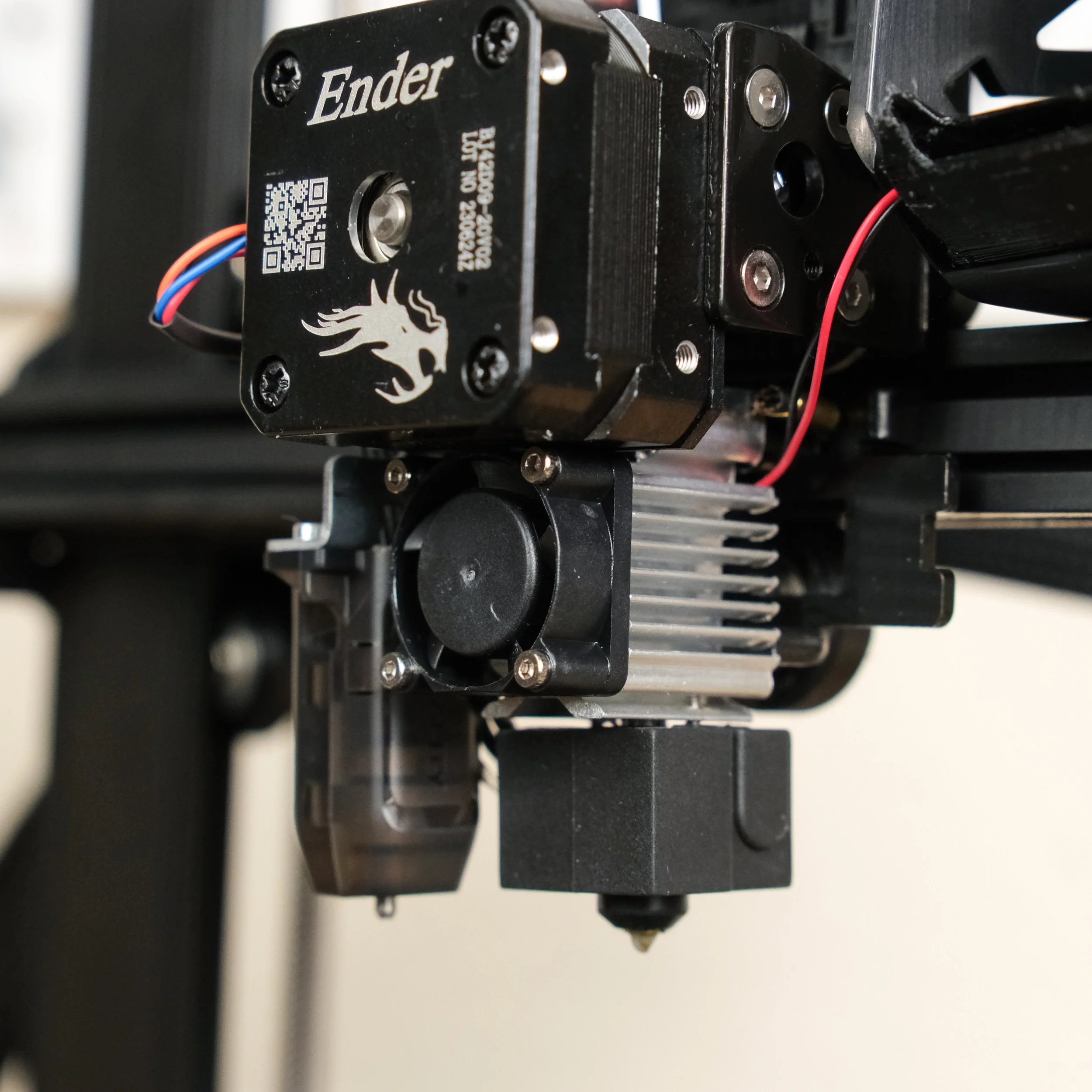

The new Sprite direct drive extruder is the most substantial change for the Ender 3 S1

The Ender 3 S1 was released in 2021, before the Ender 3 V2 Neo, and was a shift to a higher price tier. However, it comes with a lot of updated features, most notably a totally redesigned direct drive extruder known as the “Sprite” hot end. We did a full teardown of this hot end, and have been happy with the print quality it produces.

We tested the Ender 3 S1 and found that the direct drive extruder offers improved performance for prints with many small features where frequent retractions are necessary. Due to the close proximity of the extruder to the hot end, direct drive extruders require much less retraction than Bowden extruders. We typically use 7.5mm of retraction on printers such as the Ender 3 V2, but the Ender 3 S1 worked best with only 0.6mm of retraction. A lower retraction distance offers a few benefits:

Less likelihood of jamming. Frequent retractions in succession, which is required if your object has many small features, is far less likely to cause a jam. This is due to the fact that the larger retractions needed for Bowden extruders bring the heated filament backwards into the cold section of the hot end, and brings the heat with it. If this heat creeps too far up the hot end, the filament will begin to widen before it reaches the nozzle and can jam within the tubing. This issue doesn’t happen with direct drive extruders due to the shorter retraction distance.

Retractions occur much faster, which speeds up the printing time. This is not a substantial amount of time for a single retraction, but if your print includes thousands of retractions, it adds up.

The new extruder also uses a dual gear extrusion system, and uses a 3.5 : 1 gear ratio to increase the torque of the extruder motor, which allows the extruder to perform more consistently.

Like the Ender 3 V2 Neo, the printer comes with standard auto bed leveling (ABL) and a removable magnetic PC build surface. Overall, we don’t feel like the direct drive extruder is a compelling enough upgrade to make this printer worth the extra cost over the Ender 3 V2 Neo, however if you are looking to print flexible filaments, a direct drive extruder is a must, and the Ender 3 S1 is a good option for that use case.

Ender 3 S1 Pro

Shortly after the release of the Ender 3 S1, Creality released the more premium Ender 3 S1 Pro, which adds two notable functional updates:

First, the Ender 3 S1 Pro uses an all-metal hot end within the sprite extruder, which will allow you to print higher temperature materials without worry of any damage to the hot end. Printing higher temperature materials such as PETG and ABS requires temperatures around 250 C, which starts to break down the PTFE tubing that is used in the standard Ender 3 S1 hot end. Over time, you may need to replace the PTFE section after extended printing with these materials. The all-metal hot end does not have these issues.

Additionally, if you are looking to print even hotter materials like nylon, the Ender 3 S1 Pro is one of the few Creality printers that will allow you to heat the nozzle to up to 300 C. While third party all-metal hot ends are available for other Creality printers, you will need to update the firmware on these printers to increase the maximum allowed temperature from 260C.

The other major change is that the S1 Pro uses a PEI print bed, while the Ender 3 S1 uses PC steel. We found that this material is much harder to damage if you make a mistake which causes the nozzle to drag on the bed, such as when leveling the printer, so this is a welcome improvement.

Ender 3 V3 SE

The Ender 3 V3 SE’s direct drive extruder (enclosure was removed)

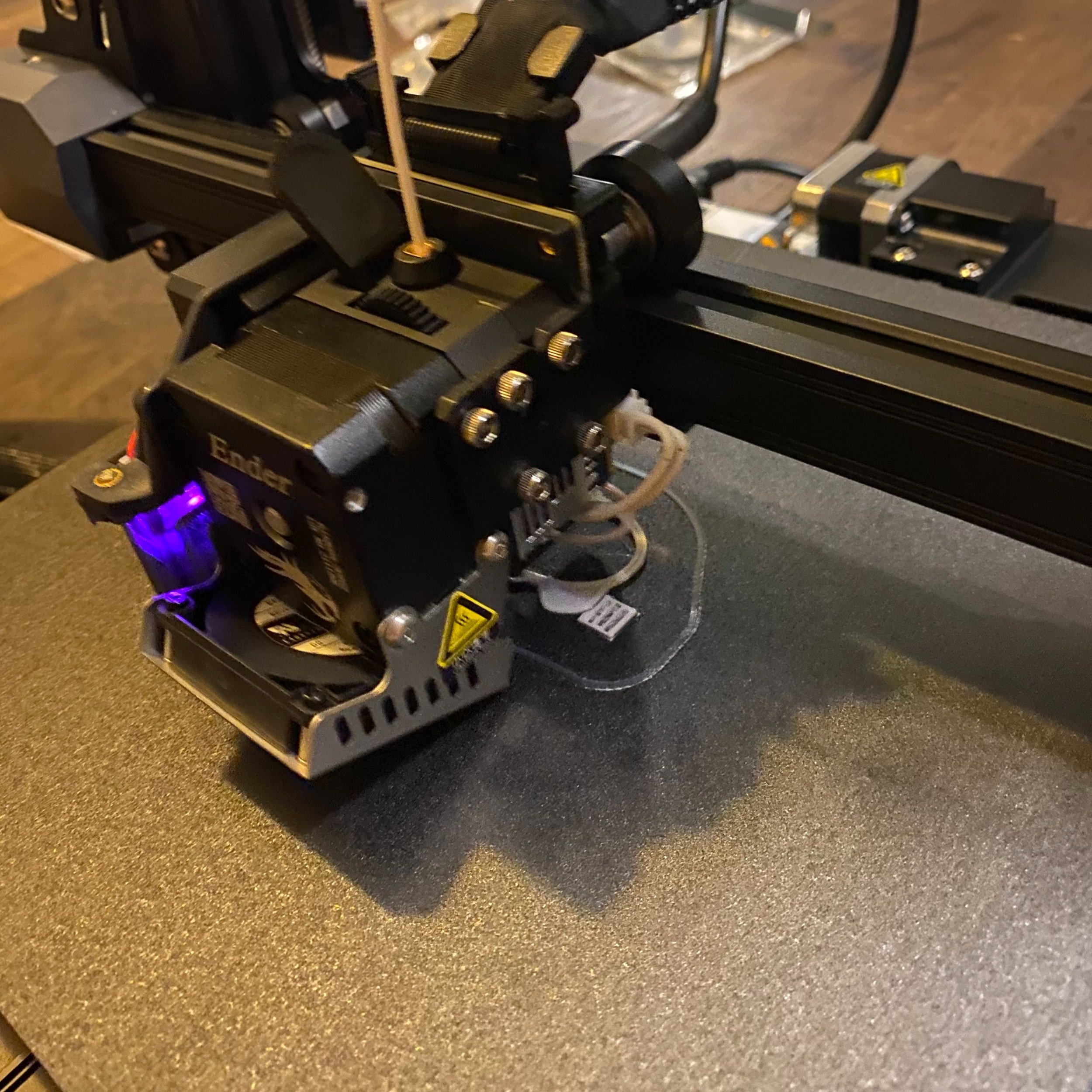

The Creality Ender 3 V3 SE (view on Amazon) is one of Creality’s newer entries into this space, and it outclasses older 3D printers such as the Ender 3 V2 Neo and Ender 3 Neo in several important ways. It maintains the same 220 x 220 x 250 mm (8.75 “ x 8.75 “ x 10”) build volume as the older Ender 3 series printers, but adds a direct drive extruder, high speed printing, and an improved user interface. Since the Ender 3 V3 SE still comes in at a similar price to the most affordable printers in Creality’s lineup, it’s an obvious top pick in this category.

If you’re new to 3D printing, there’s a lot to like with the Ender 3 V3 SE. Creality has simplified the assembly process compared to its older Ender series printers, and a new strain gauge sensor allows the printer to self-configure the Z offset for automatic bed leveling. From our testing, this is an easy printer to assemble and calibrate, and produces great prints out of the box.

The direct drive extruder sets the Ender 3 V3 SE apart from other entry-level 3D printers.

For users at all skill levels, the direct drive Sprite extruder sets the Ender 3 V3 SE (and its sibling, the Ender 3 V3 KE) apart from other entry-level Creality 3D printers. Direct drive extruders are faster and more reliable than their Bowden counterparts, and also make it easier to print with flexible filament such as TPU. This has often been a feature found on more expensive machines, and it’s great to see at the more affordable end of Creality’s lineup.

The Sprite extruder, combined with some structural improvements, make the Ender 3 V3 SE capable of much faster print speeds than most of Creality’s other printers. In our testing, we easily printed at 175 mm/s without compromising on print quality.

We highly recommend the Creality Ender 3 V3 SE and feel that it offers excellent value for its price. We currently consider this to be the baseline Creality 3D printer and recommend it over older printers such as the Ender 3 Neo due to its improved feature set.

You can look at the Creality Ender 3 V3 SE on Amazon by clicking here.

Ender 3 V3 KE

The Ender 3 KE adds more features to the Ender 3 V3 SE at a moderate price increase, but we are very happy with what Creality added. It has all the features of the Ender 3 V3 SE, but with the following improvements:

the PC bed was replaced by a PEI build surface, which is less prone to damage and has much easier part removal once the bed cools. PEI is a premium build surface that we recommend upgrading to on machines with other surfaces

The use of linear rails on both the X and Y axis (the V3 SE uses them on X but not Y), which provides more stability

A redesigned hot end with a larger heat cartridge and a longer heated area, which enables higher flow rate printing, which is important when trying to print very fast

Dual cooling fans, which provides superior overhang performance and addresses issues where overhang performance can be degraded for certain part orientations

The higher flow hot-end allows for faster printing

Dual cooling fans improve overhang performance

Choosing an Ender 3 Printer

Now that you are more familiar with the 3D printers in the Ender 3 series, here are our recommendations based on our experience with these machines.

Best First 3D Printer

We think the Ender 3 V3 SE (view on Amazon) is the best choice for a first 3D printer since it has reliability upgrades and a direct drive extruder to help avoid early issues, as well as auto bed leveling, which will save a lot of headaches that come with initial issues related to incorrect bed leveling. With your first 3D printer, you’ll be learning a lot about how printers work and dialing in the quality of 3D prints, so reliability is very important to ensure you have fun and are not encountering frustrating issues while you learn. If you’d prefer a printer that is sleeker and easier to assemble, stepping up the the Ender 3 V3 KE (view on Amazon) offers more features for a modest price increase

Best Low Cost 3D Printer

If you are looking to spend as little as possible, and you are not intimidated by a steeper learning curve and more involved assembly process, the Ender 3 (view on Amazon) is the cheapest printer you can buy. You can apply many of the upgrades yourself, such as the glass bed and an upgraded power supply, and come out saving money on the printer even after the cost of upgrading. The Ender 3 has a large community and more history of upgrades for you to build on, and the print quality is capable of matching much more expensive machines.

We typically recommend going with the Ender 3 Neo (view on Amazon) , which costs a bit more but has far more features.

Best 3D Printer for Printing a Variety of Materials

The most versatile 3D printer in the Ender 3 series is the Ender 3 S1 Pro (view on Amazon). The direct drive extruder allows you to easily work with flexible filaments, while the all-metal hot end allows you to print high temperature materials like PC or Nylon. If you like to experiment with different materials and are looking for the most capable printer, the Ender 3 S1 Pro is a great choice. If you are also considering the Prusa MK3S+, we’d suggest talking a look at our in-depth comparison here.

Overall Recommendation

We think the Ender 3 V2 SE (Amazon link) is the best all-around 3D printer in the Ender 3 series since it packs in a lot of great upgrades for a reasonable price and is still a bargain compared to other printers in its class. If you are more budget conscious, we’d recommend the Ender 3 Neo (view on Amazon) which offers most of the modern features at a very low price. Though the base Ender 3 is somewhat cheaper, we think the many upgrades on the Ender 3 Neo are well worth the additional cost.

If you prefer to examine the specs of each printer, you can use the table below to compare these printers side by side and decide which of these 3D printers will work for you: